Universal Parametric Rugged Box by Rainer Backes is perfect. Read more below if you need to.

Universal Parametric Rugged Box by Rainer Backes

Universal Parametric Rugged Box by Rainer Backes

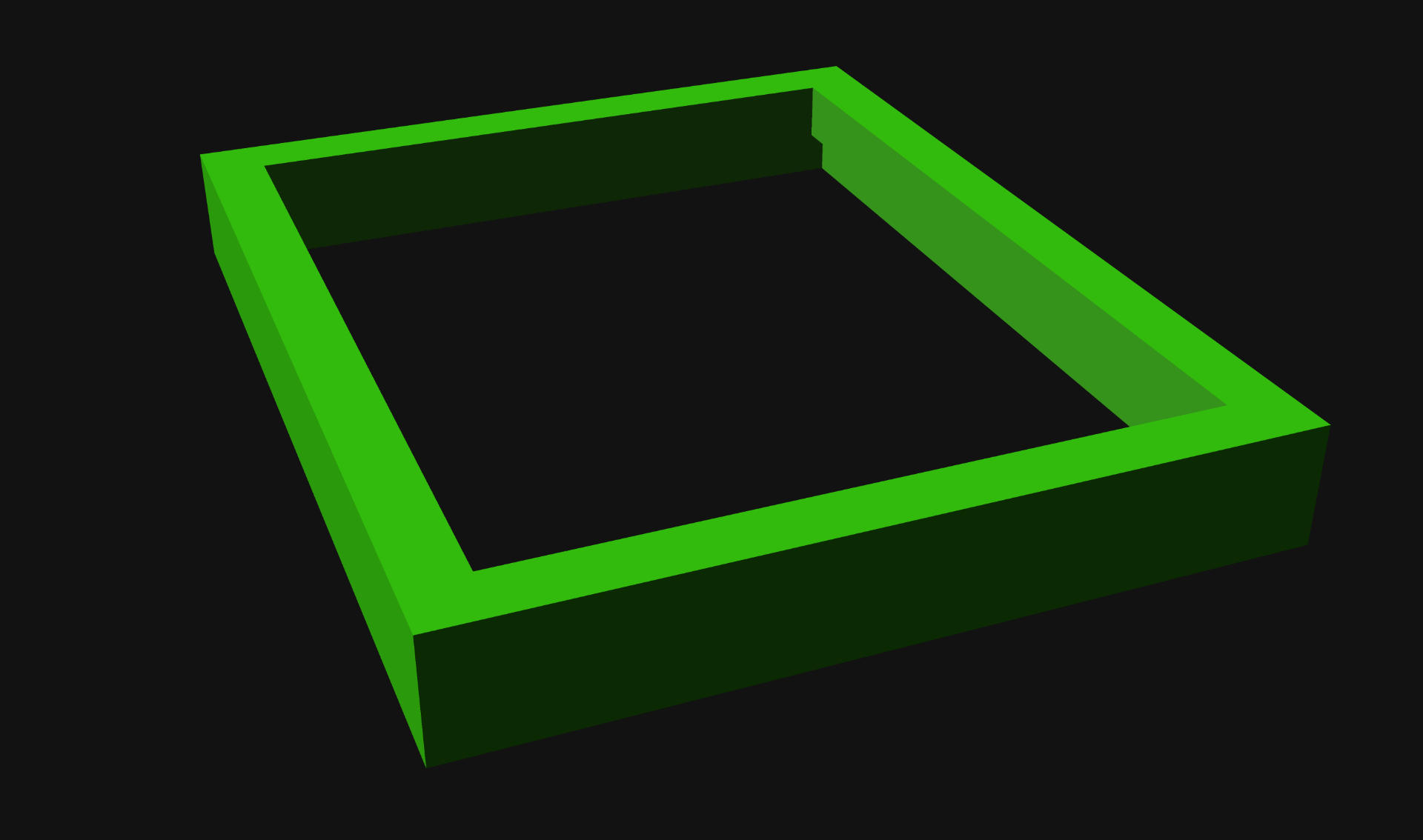

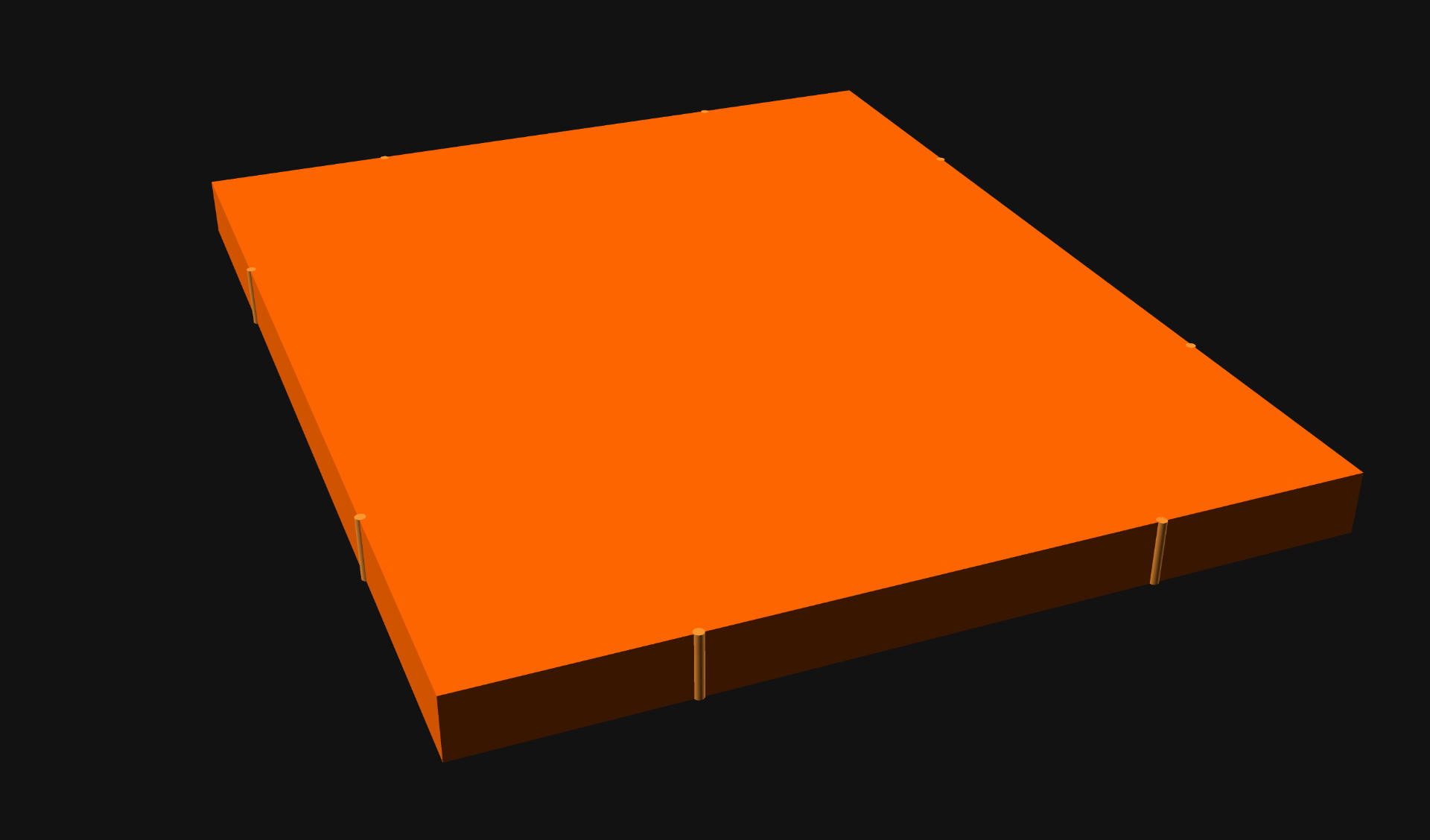

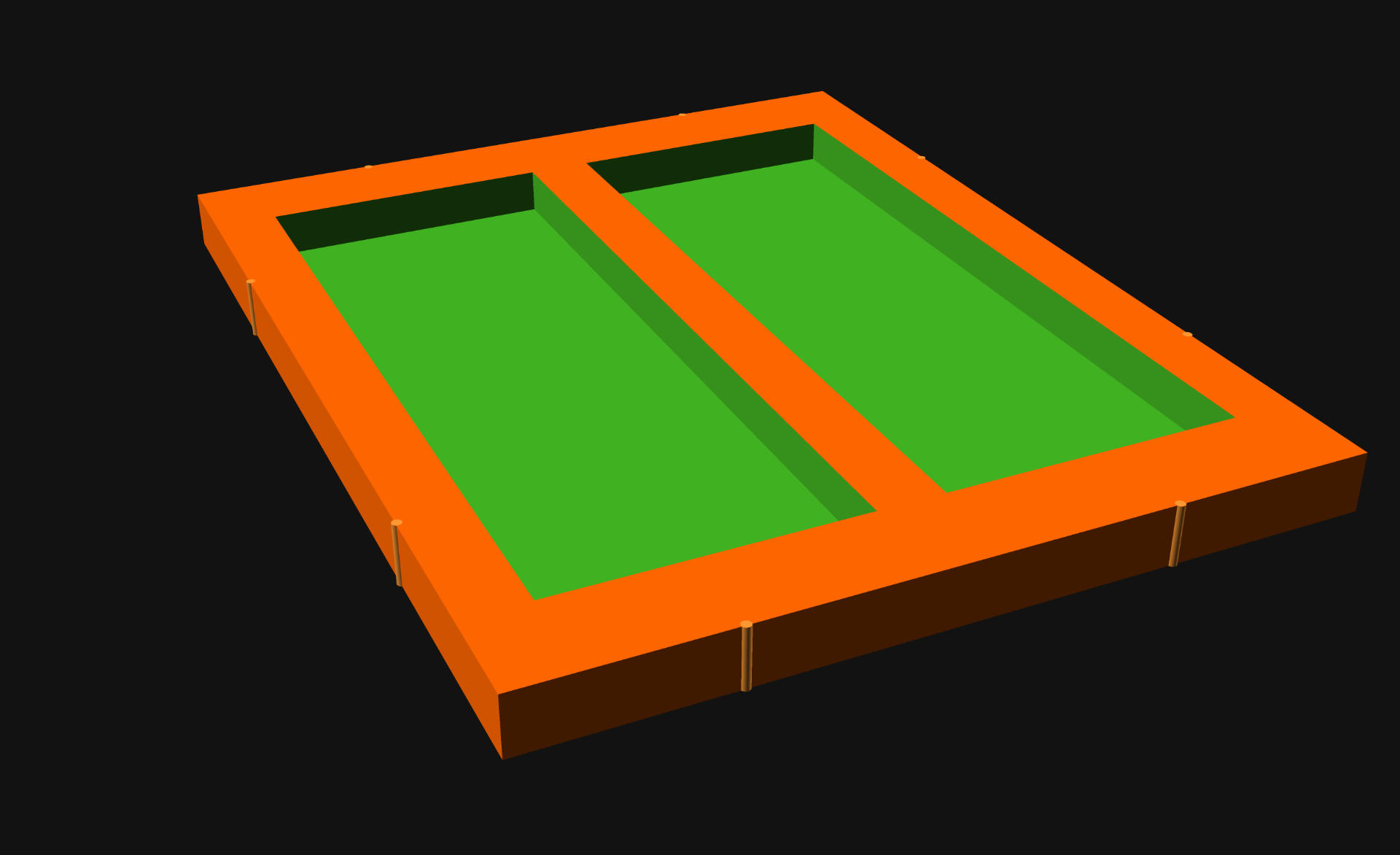

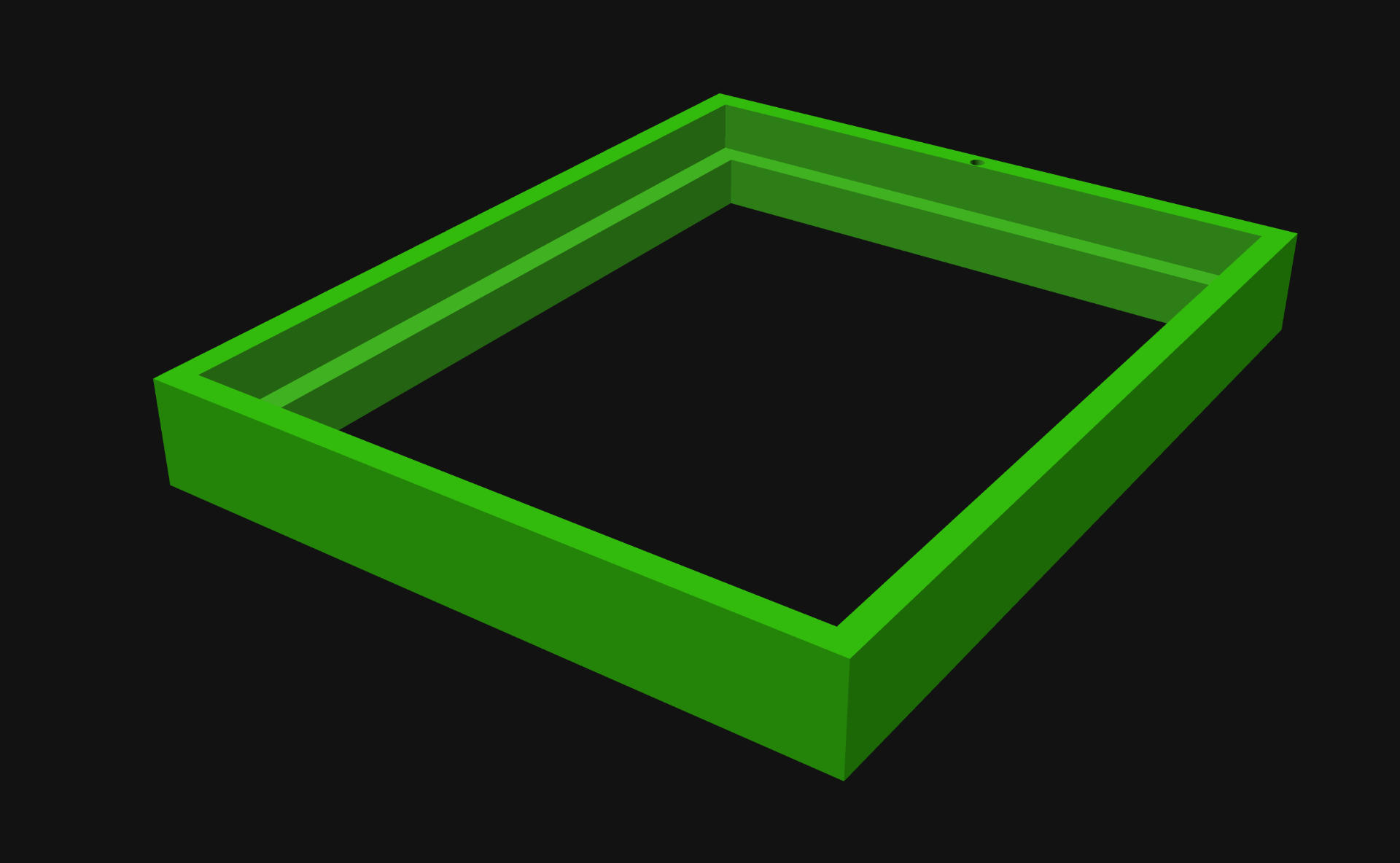

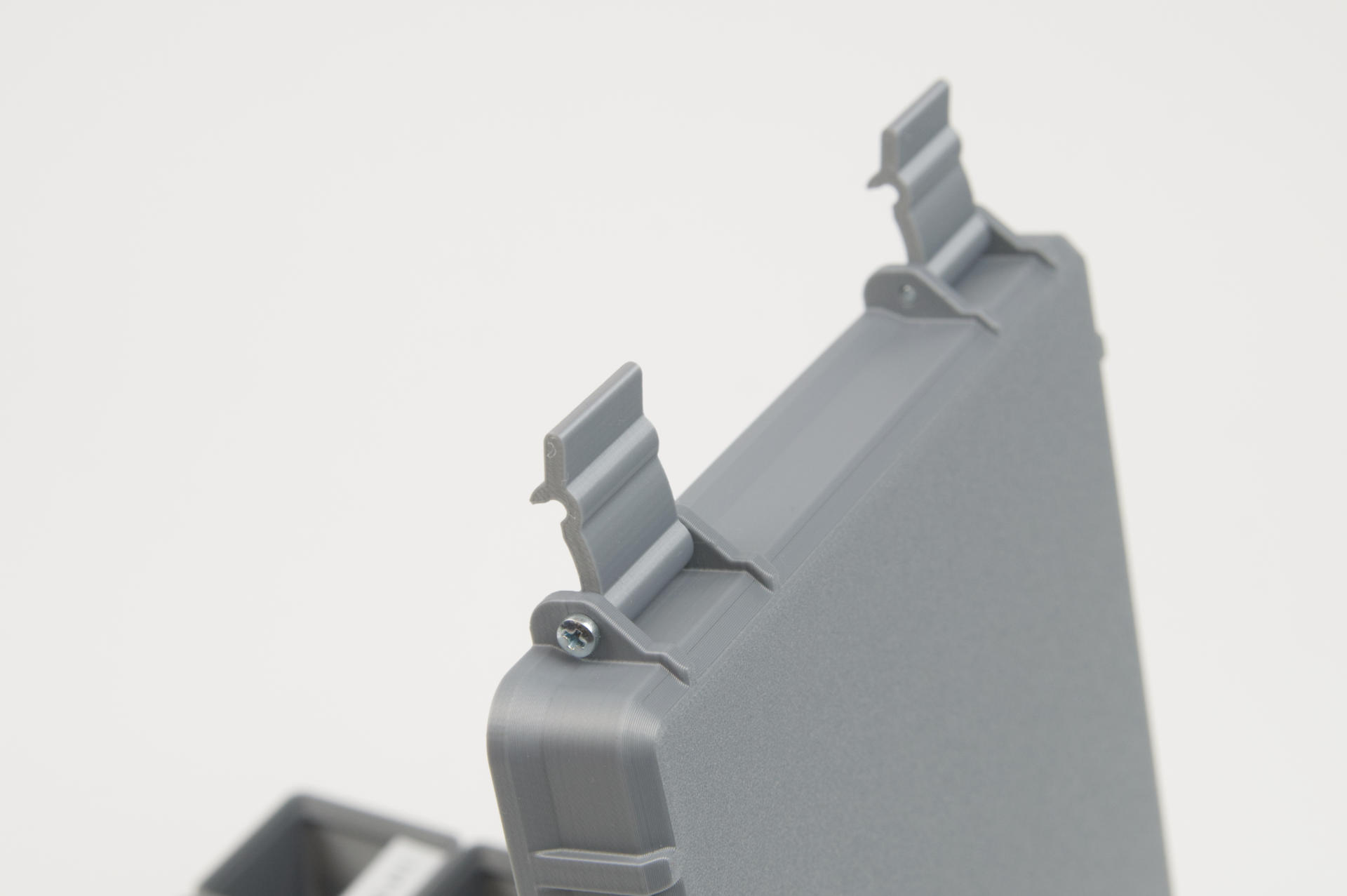

I mentioned “Rugged Boxes” a bit in my Hardware Gridbox post, but the idea is basically a small box with a latch that is rugged, so it’s like a tiny Pelican case that you can print yourself.

It’s the sort of thing that if you want one a specific size for a specific use that someone else also needs, you might find it easily… but if you want it a custom size just for your specific application, well… you need to be able to adjust the design. There are a bunch of parametric designs that work with Fusion 360 (which I do not use) and I don’t know if Rugged Box (Parametric) by Whity is the original but it’s definitely quite popular.

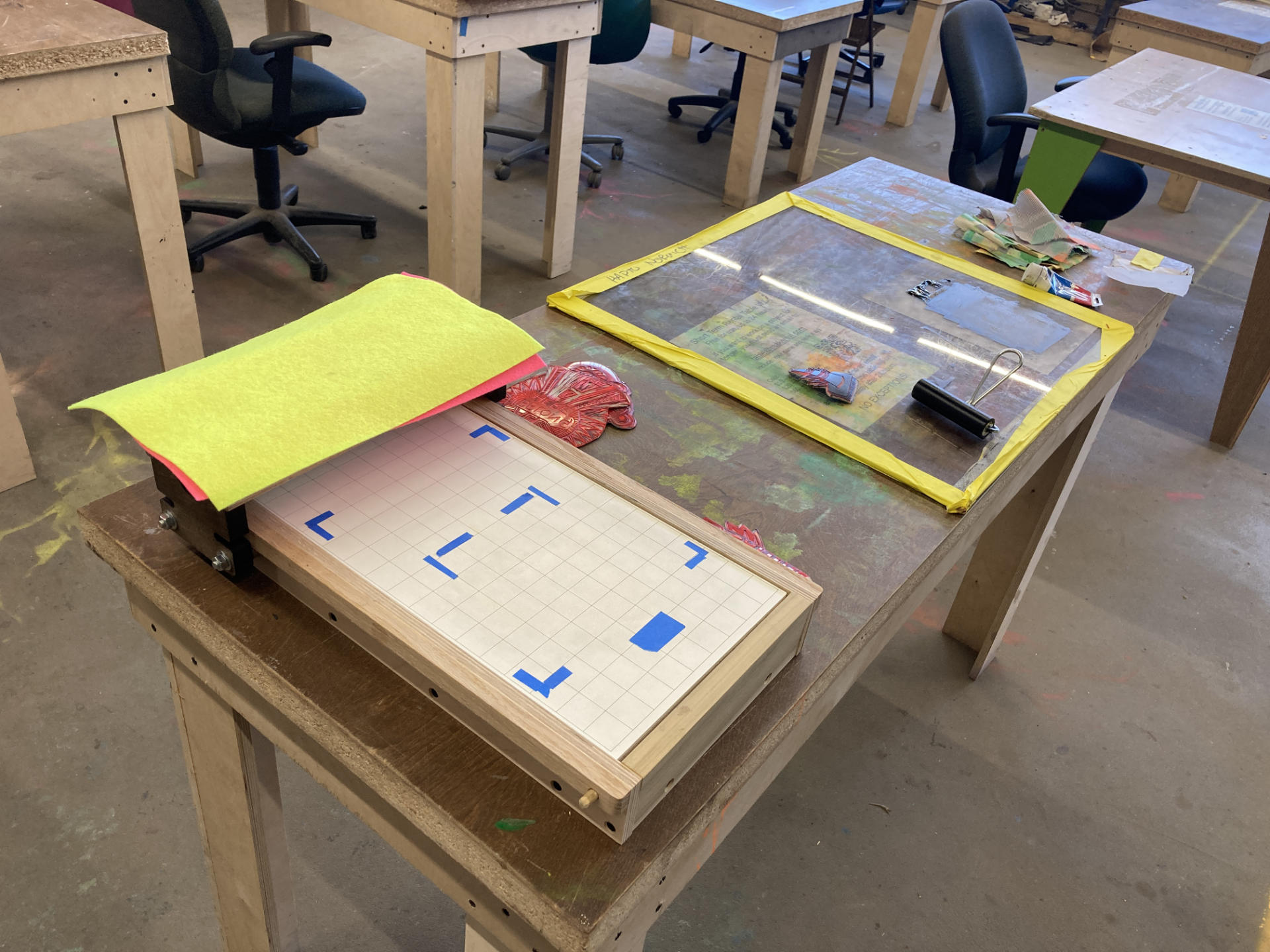

Here’s an 80x80x60 version I printed, but I wanted something smaller. I tried this one but didn’t like it. So finally, we’ve got one that ticks all the boxes!

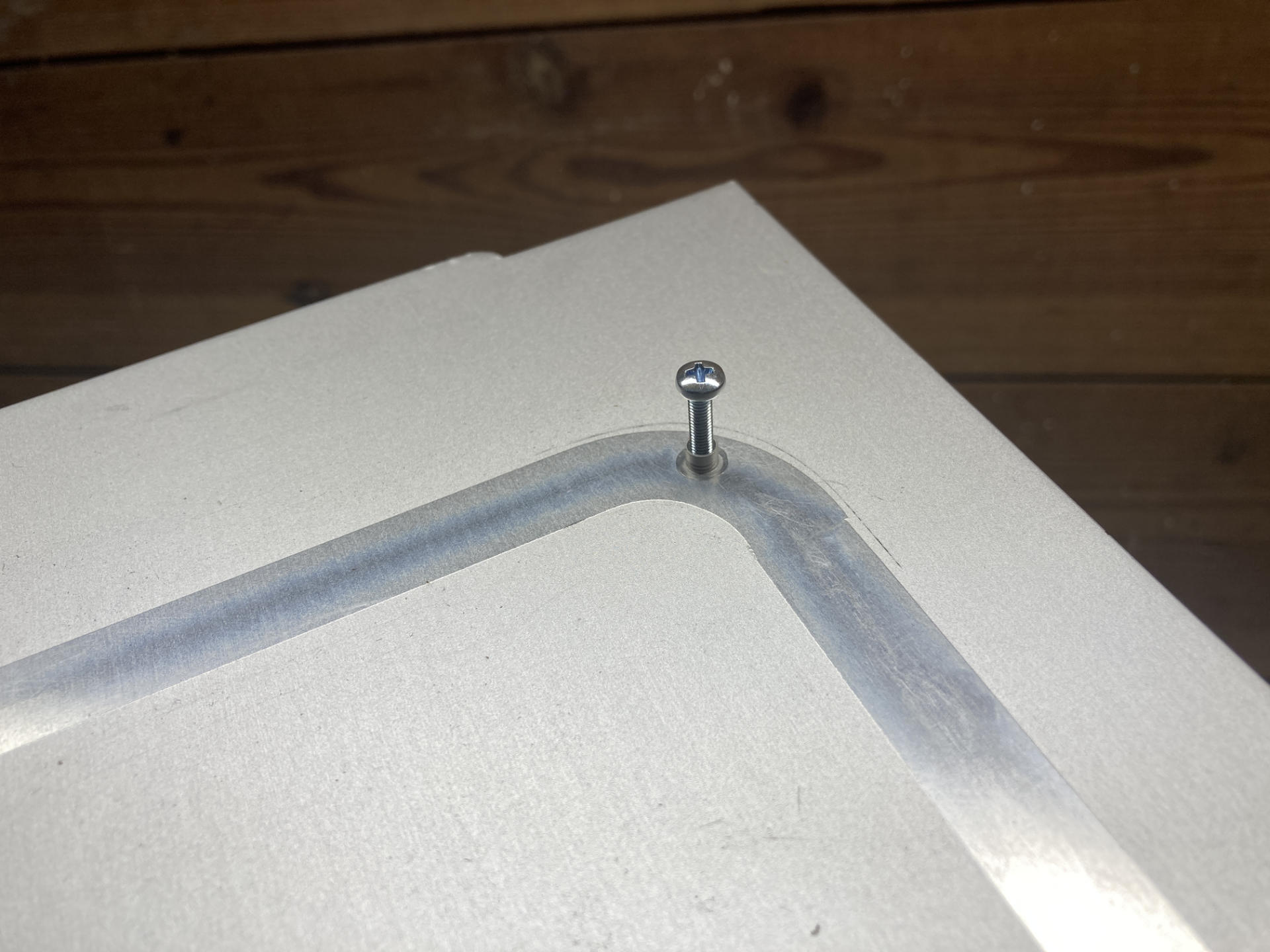

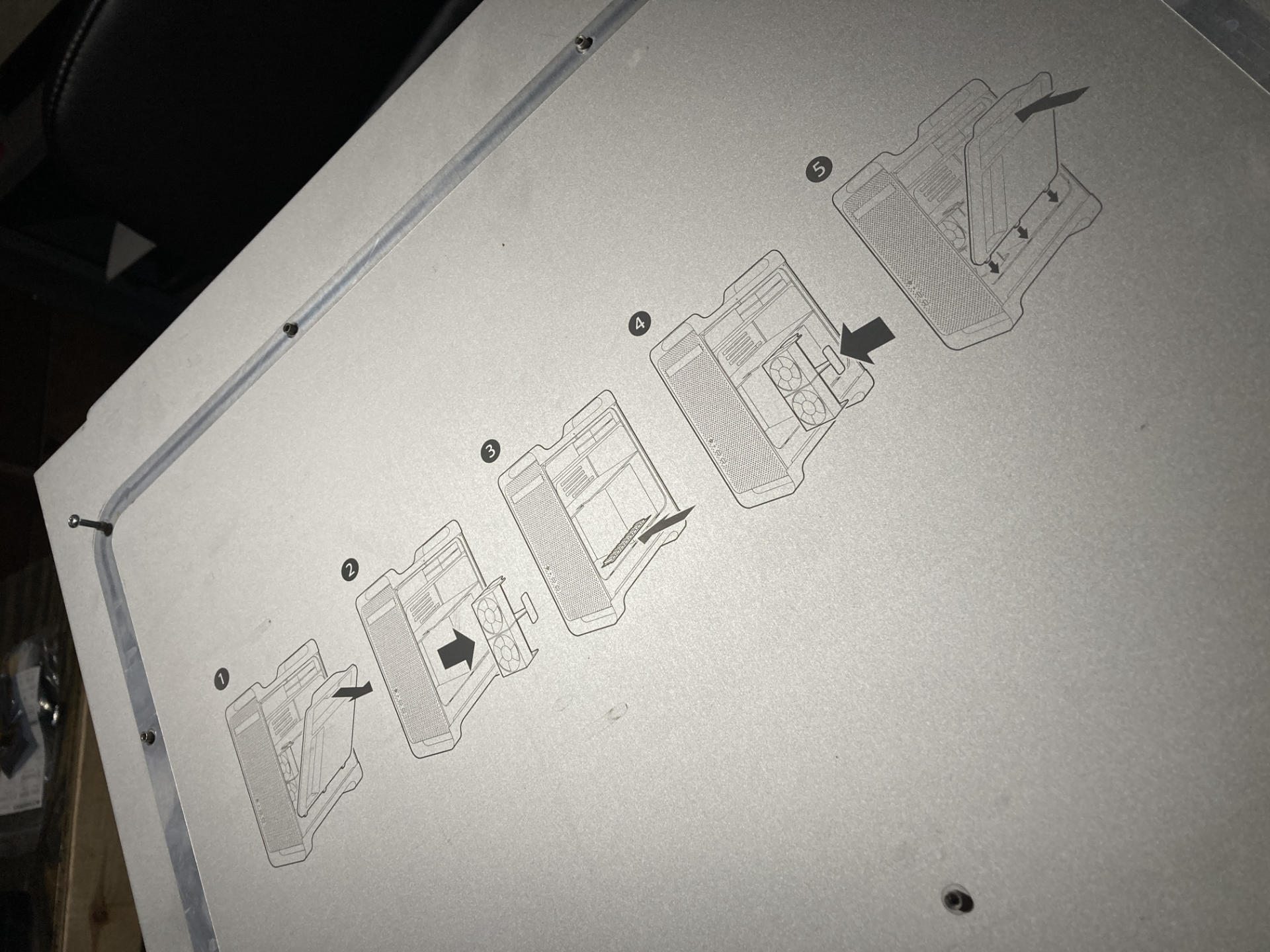

Universal Parametric Rugged Box by Rainer Backes is perfect. And by “perfect” I mean it’s written in OpenSCAD, and it works. At least my first print worked, as you can see by the photos. I haven’t pushed the design too hard yet, but being done in OpenSCAD means I can go crazy with it.

This saves me the trouble of having to write my own, which I did start working on. While I do enjoy designing objects I also enjoy finding code that someone else wrote that does exactly what I need. It looks like Rainer has a bunch of models written in OpenSCAD, so I may need to dig through the others for inspiration. Thanks, Rainer Backes!