I recently got a NIIMBOT D11 label maker. I’ve had a DYMO for years (and even shared a great tip for it!) The NIIMBOT has some nice features but also a few things that are sort of annoying, and I’ll ramble on about those things in this post.

Here’s a short list of the good things:

- It uses an app

- It has a built-in battery

- It’s inexpensive

- It’s pretty simple

- You can make fully custom labels

And another list of the bad things:

- It uses an app

- It has a built-in battery

- It cannot stand up

- It’s complicated

The App

Okay, let’s start with the first item on both lists… the app. Many years ago I got a DYMO LabelManager 160 Portable Label Maker. It’s dead simple to use, does not need an app, and just… makes labels. We have one at work, and at my previous job, and anyone can use it quite easily.

With an app, you first need to install an app (of course) and that is the only way you can use a NIIMBOT. There is no keypad, you can’t connect it to a computer (which would be awesome) and so yeah, an app. The world is full of apps now, and you need them to do things, which means you need a mobile device to do things.

And yes, the NIIMBOT is a Chinese product, so the app is also from China, so if you are hesitant about installing apps from China, you are out of luck. Supposedly you do not need to register to use the app, unless you want to save labels/templates for future use. I found this out after I registered. The app also has “Premium” content, where it shows you clip art and fonts that you cannot use unless you pay, which is quite annoying.

The Battery

It has a built-in battery, which is of course good and bad. When the battery dies, it’s not going to work until you charge it. You can’t swap in a fresh set of cells. Of course this also means it won’t kill a set of 6 AAA batteries like the DYMO might. The built-in battery thing is a toss up but everything nowadays seems to be headed that way. Once the internal battery is dead I guess you just chuck the whole unit into the bin. More rubbish.

The Cost

The NIIMBOT D11 costs just under $20 USD, which isn’t too bad. My DYMO purchased in 2017 was about $10 USD (and is currently $45 USD!?!?) of course you can get an old school embossing label makers for $12 as well, and no batteries are needed!

It cannot stand on its own…

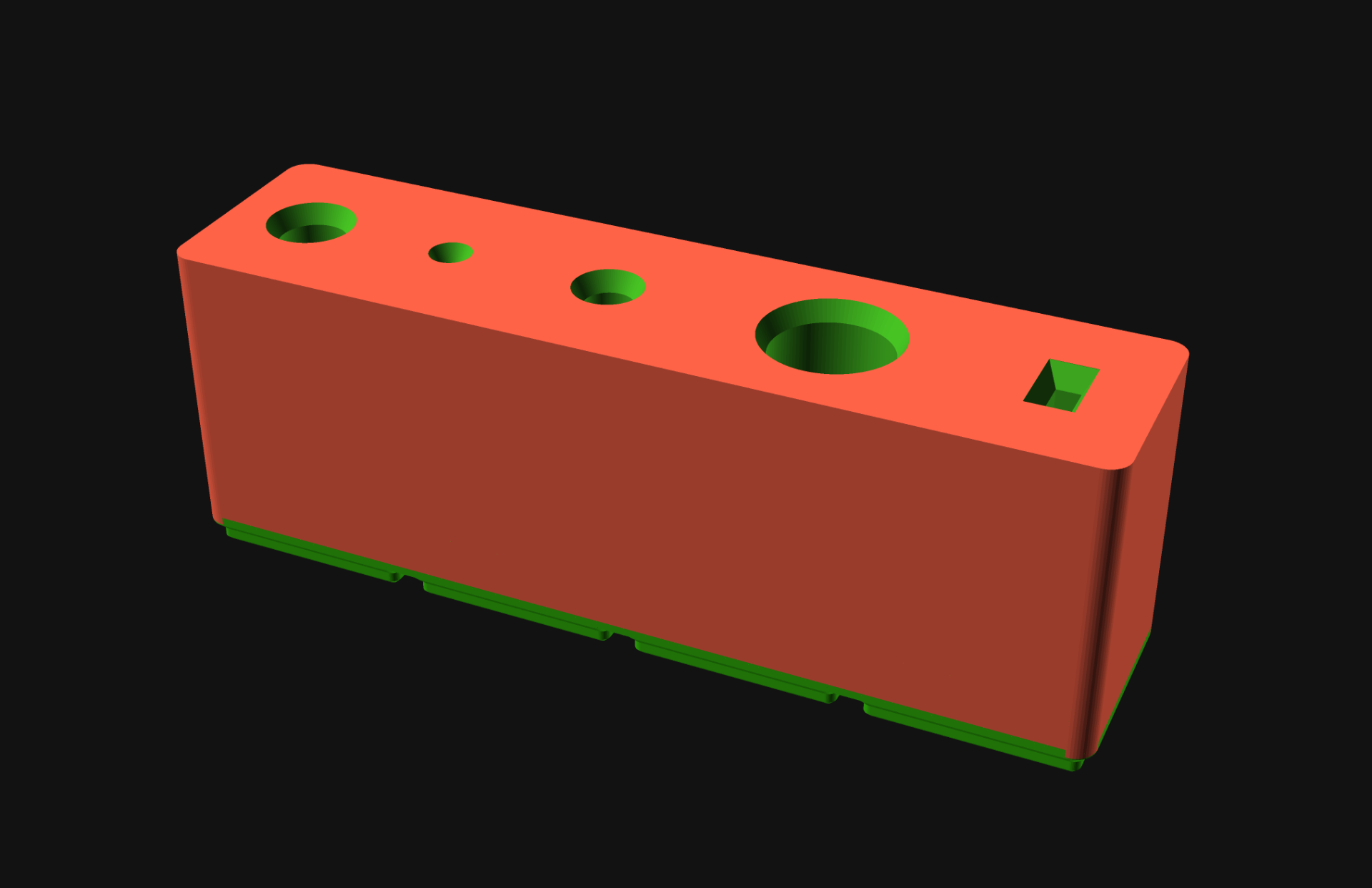

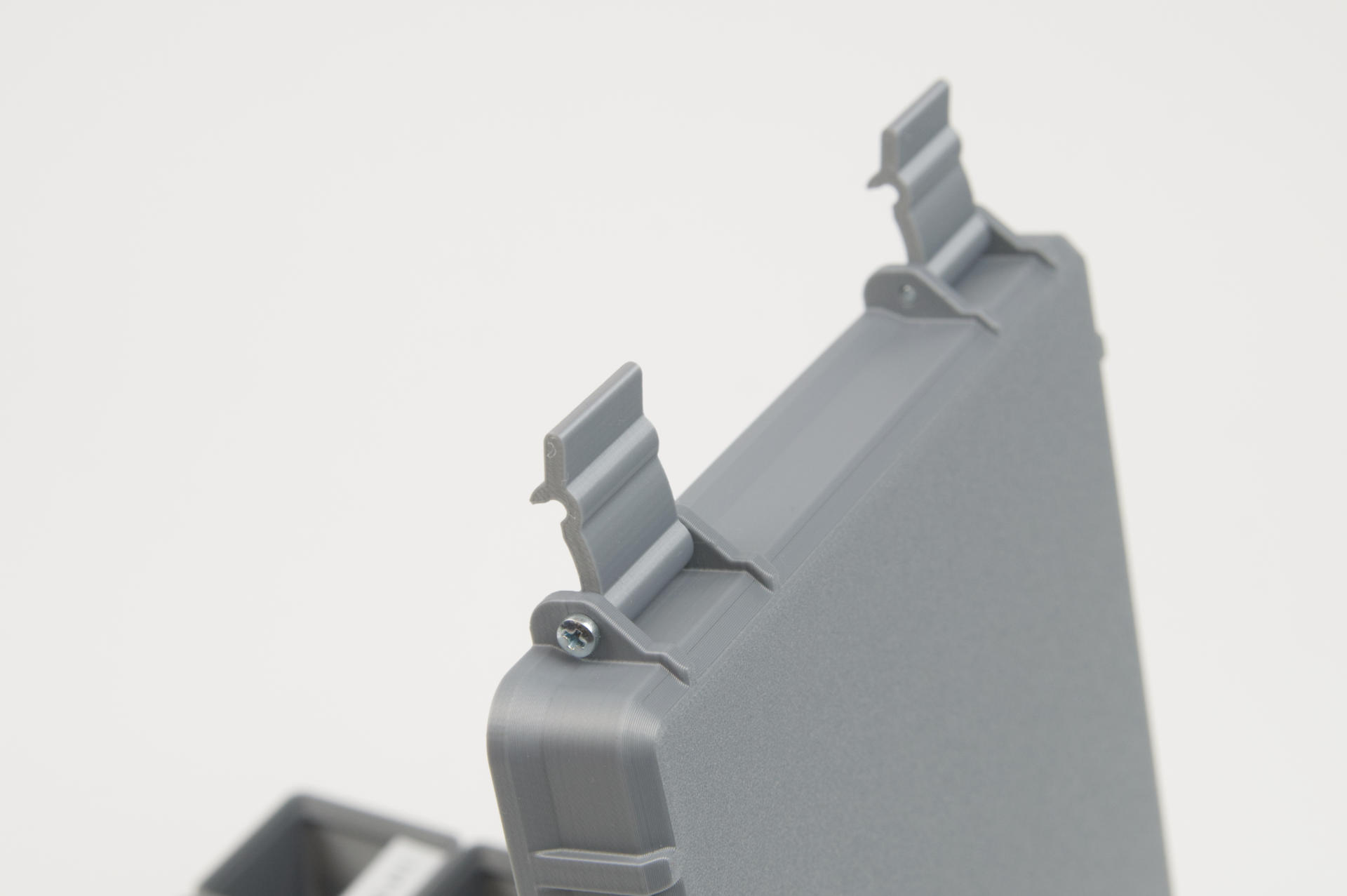

The strange design choice to add a completely rounded bottom to the unit means it cannot stand upright. I fixed that with a 3D printed NIIMBOT D11 Stand.

Simple

If you just want to print labels, it’s pretty simple. In some ways using the app can be easier than using the keypad on a DYMO 160. So yeah, as long as you have no issues using the app, you get simple.

Complicated

If you want to get complicated, you can. As I mentioned, completely custom labels are possible but they are more work. If you don’t like some of the aspects of the app (China, Premium content, an account) or have issues connecting via Bluetooth, well… it can get more complicated.

Completely Custom Labels

Now for some good news. Since you can load any image into the app, you can create completely custom labels outside of the app. Just use your favorite software to design a label the proper size (in one color) and export it as an image file (PNG or JPG) and then load that into the app and print it. This works well, but is obviously more work than just doing the label design within the app. I used Inkscape on my desktop computer, but for you mobile freaks you can probably figure out some mobile app that can work.

One More Bad

I saw a YouTube review of a NIIMBOT printer and supposedly the reviewer had a NIIMBOT made by… not NIIMBOT. Yes, there are fake/counterfeit units. NIIMBOT themselves even note that there is a fake app you need to avoid. So fake hardware and fake software are things you need to avoid when dealing with this device. Fun! (No, not fun. Bad.)

Whew! With all that out of the way, the labels themselves are good. The app can certainly be easy to use, and spits out labels quickly and they stick well. So yeah, a label maker should be simple, and the NIIMBOT D11 certainly can be simple.

Note: This post contains an Affiliate Link. Read More.