Back in 2015 I became a Producer for Maker Faire Milwaukee, and helped put on the Faire for the next four years until 2019. Life changed a lot in 2020 and I did take part in the event as a Maker in 2021 and 2022, but life got a little upset in 2023 so I just attended as an Attendee. Well, it’s 2024 and I’m back as a Maker!

So come on down to the 2024 Edition of Maker Faire Milwaukee happening on November 23rd & 24th November 2nd & 3rd at Discovery World and see Pete’s Prints.

HEY! So yes, the date has changed! It was November 23rd & 24th but is now November 2nd & 3rd, 2024.

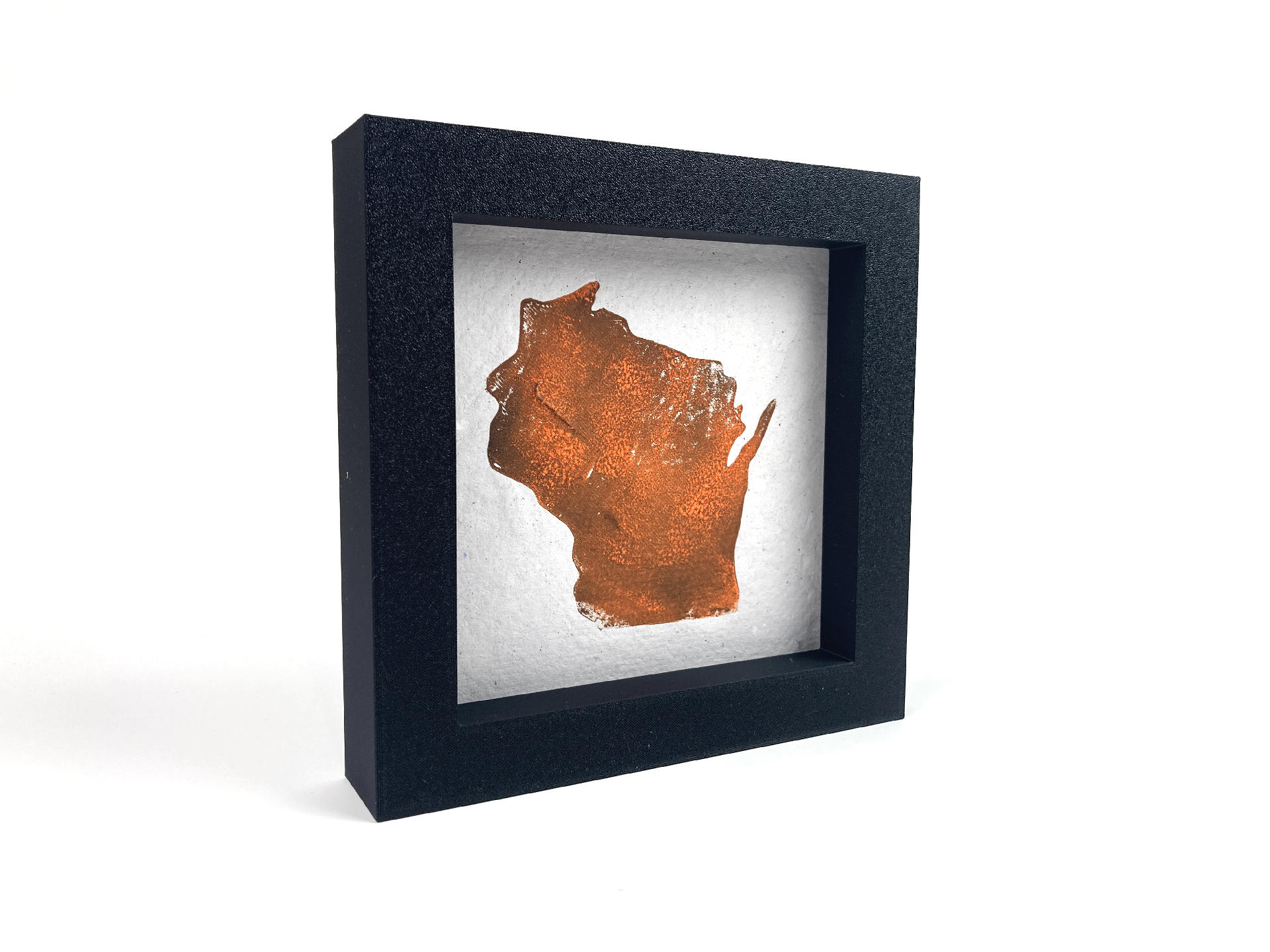

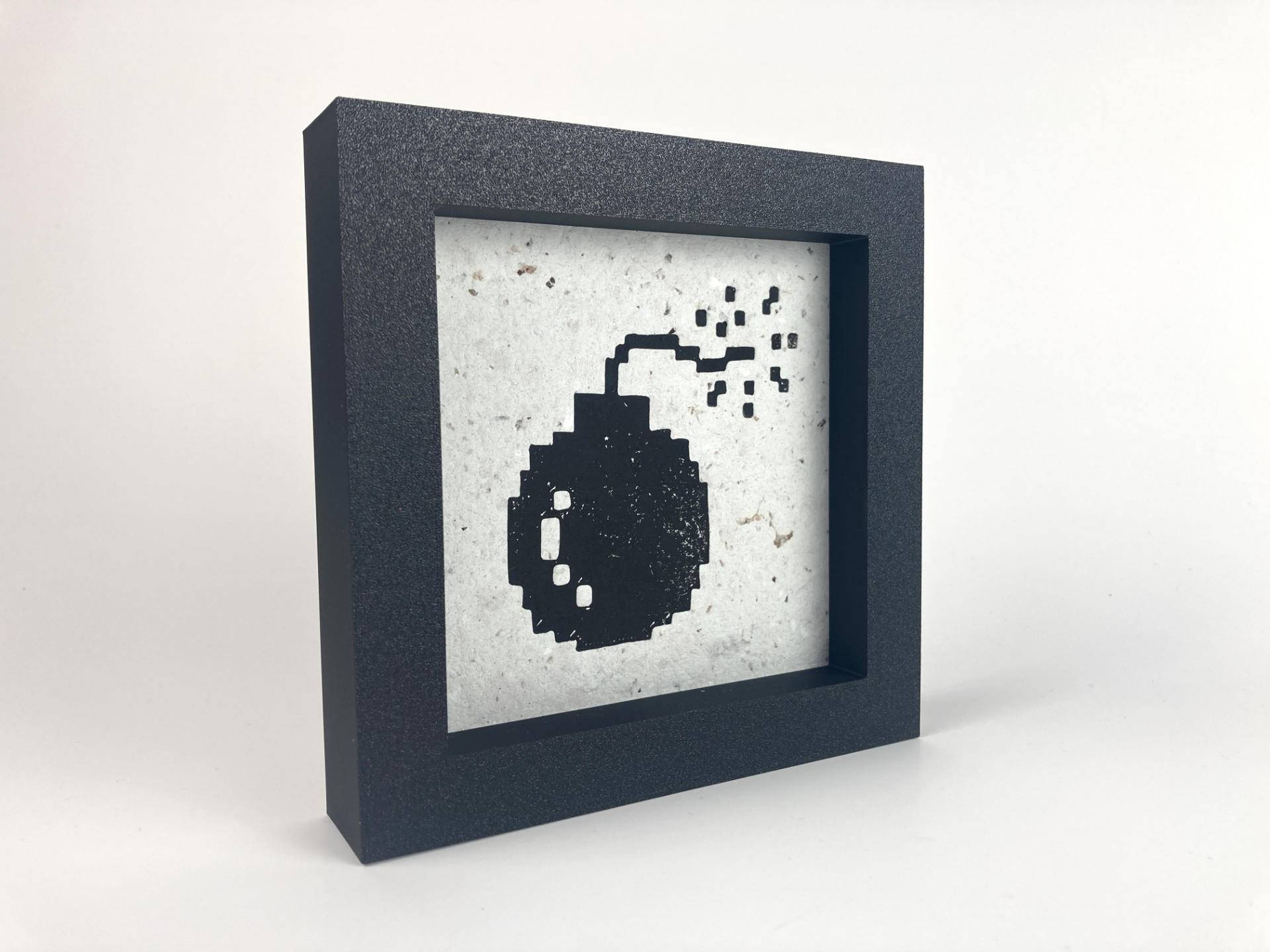

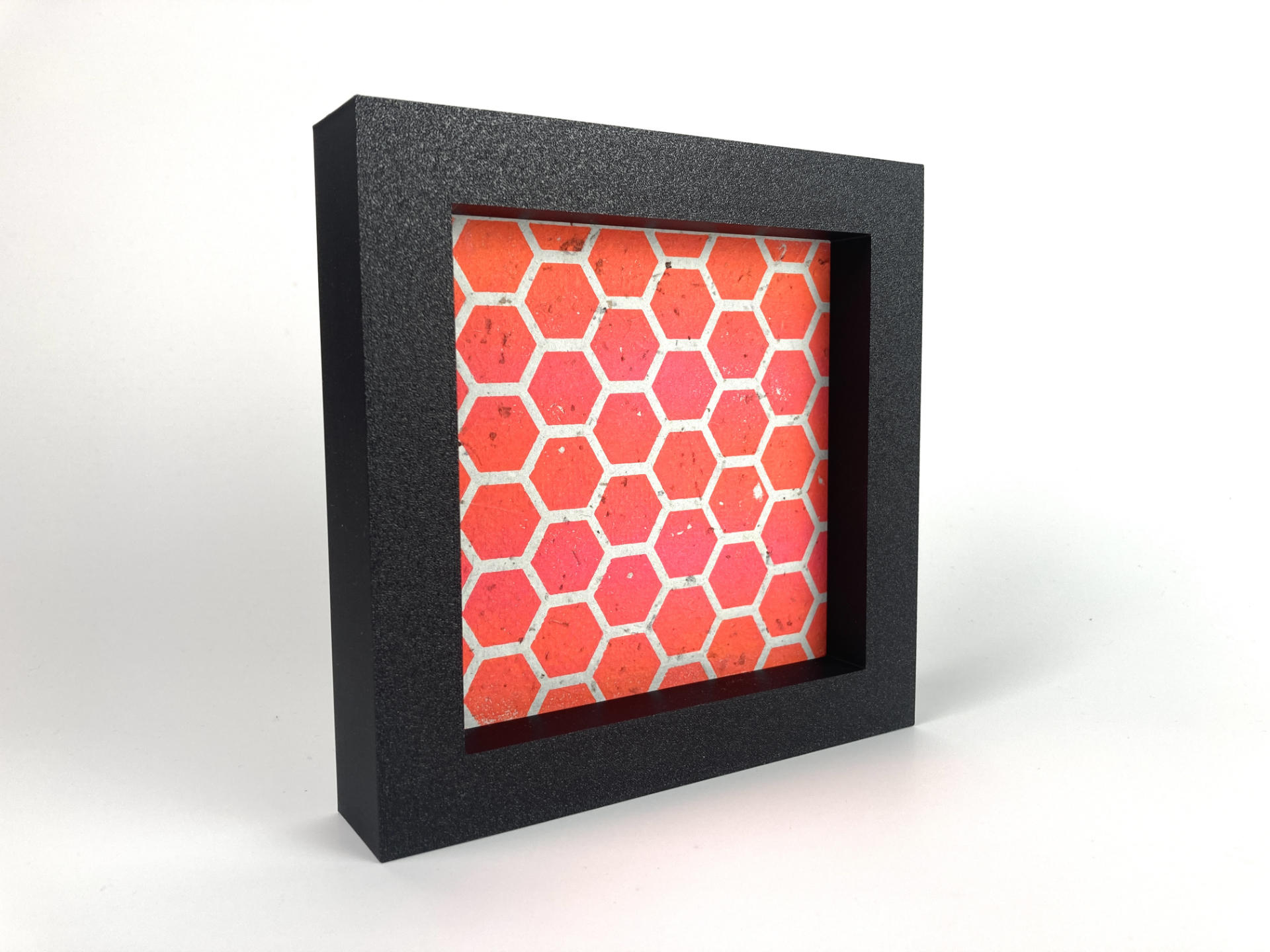

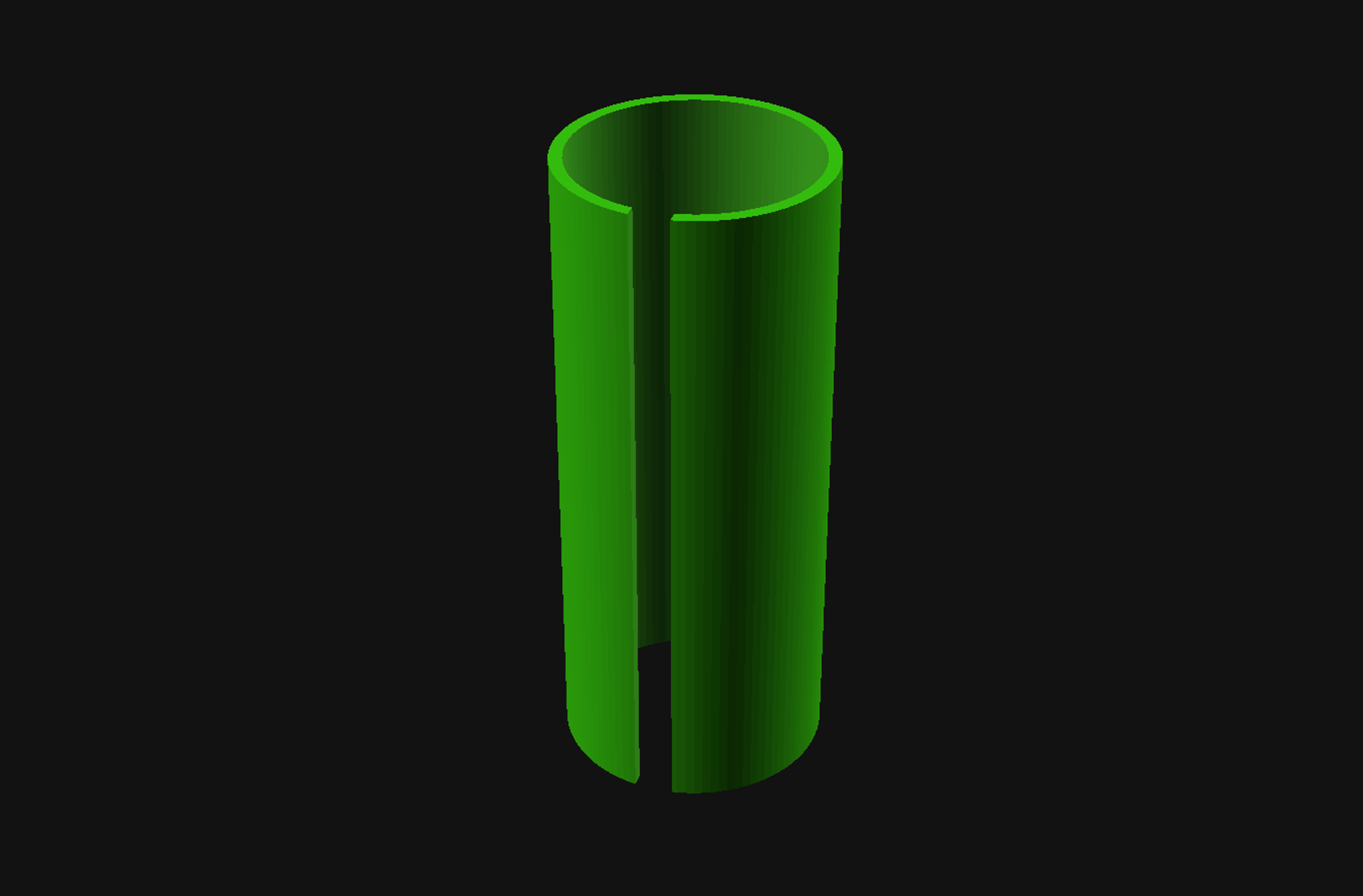

I will be there to show off my unique relief printmaking process. If you missed it, I designed and 3D printed my own mould & deckle and I make my own paper, mostly from recycled junk mail and other scraps of paper, and I then 3D print printing plates and print with them (onto the handmade paper) using a DIY printing press I assembled. Oh, I also 3D print frames for the prints.

Yeah, that’s a lot, so here’s a list of all of the posts I’ve written about my printmaking endeavors over the last year or so:

- 3D Printed Mould and Deckle

- Making Paper

- Paper Making (Again)

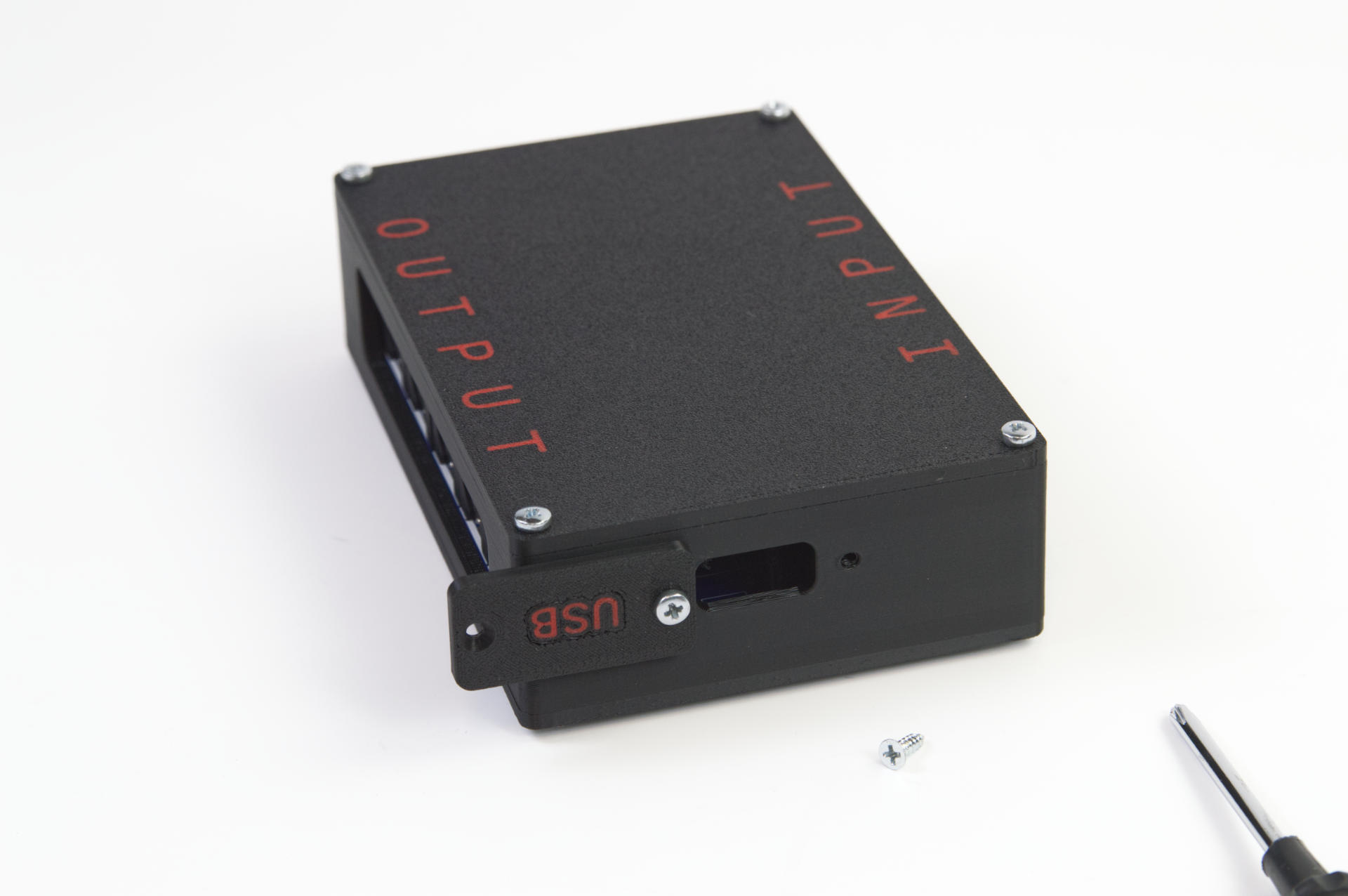

- Provisional Press

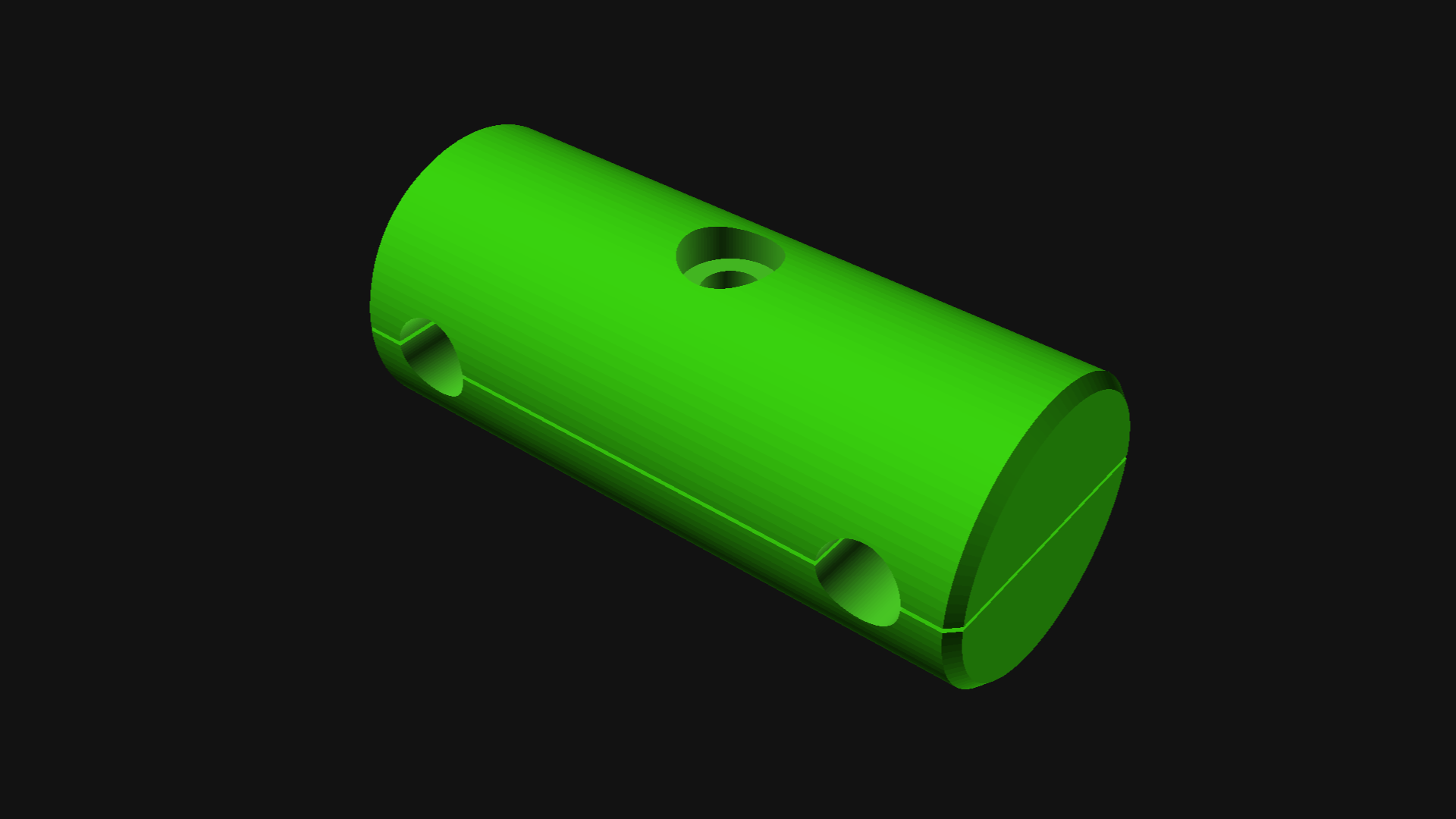

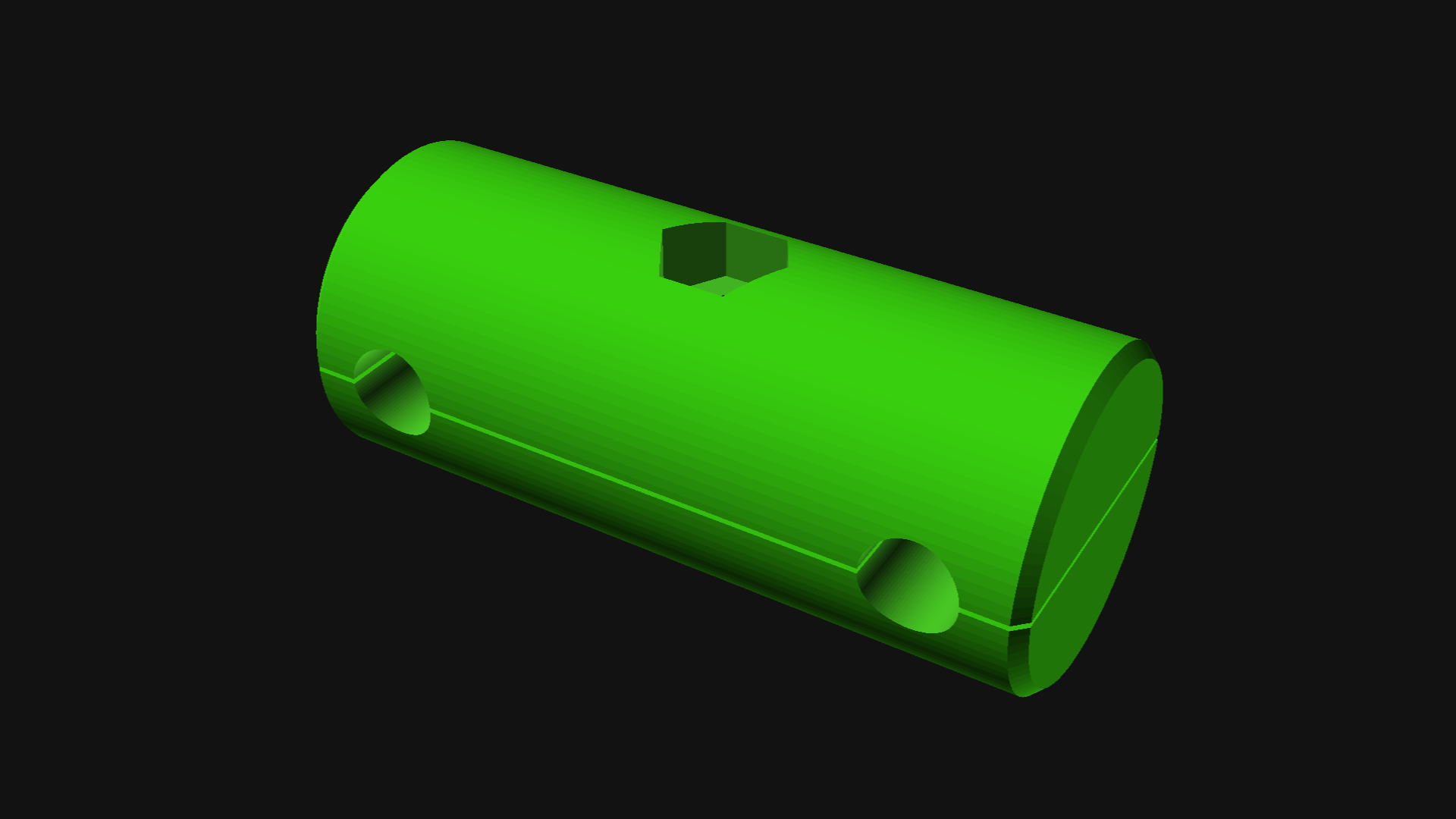

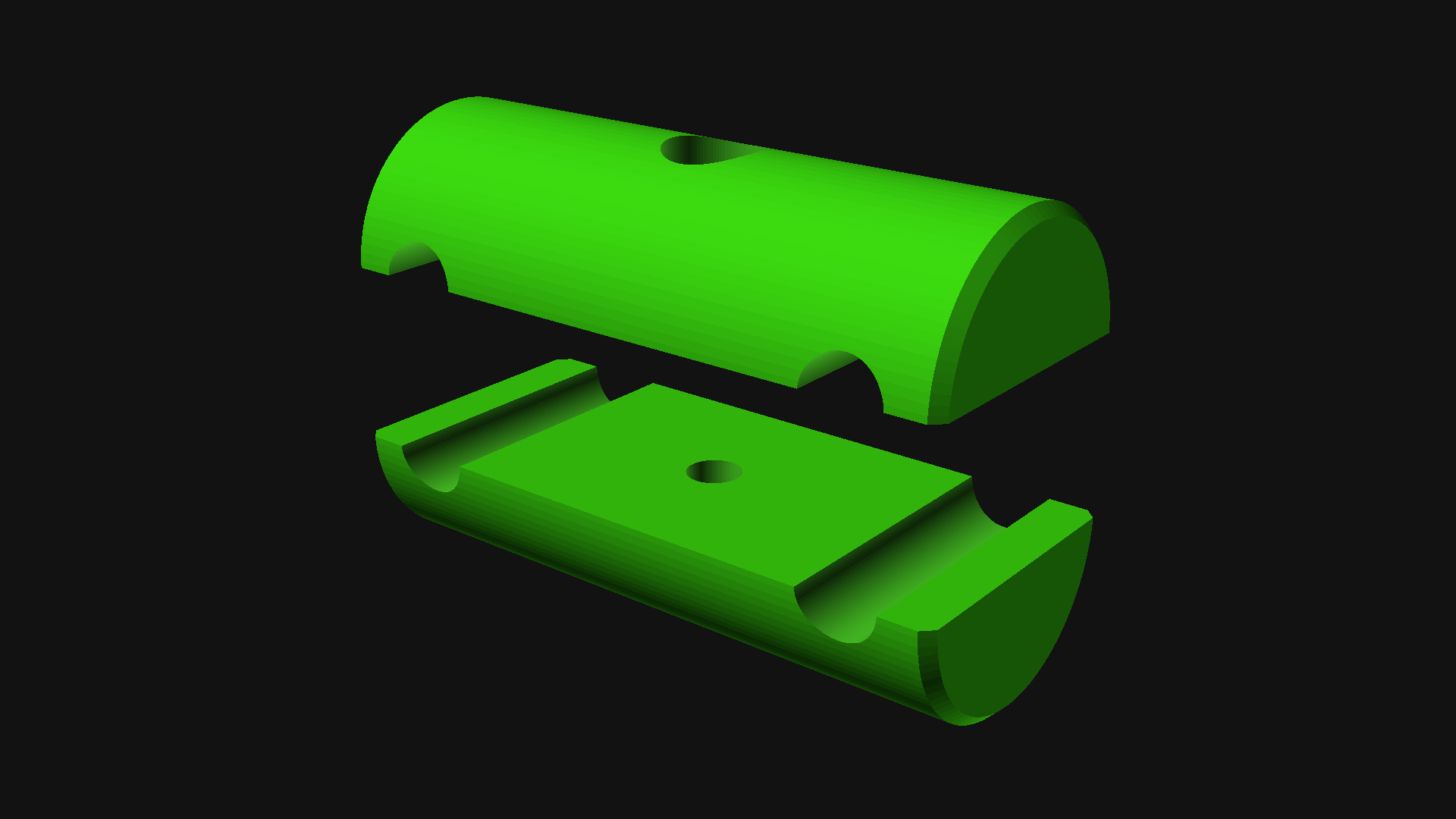

- Printmaking Registration Pins

- How I 3D Print Printing Plates

- 3D Printed Printing Plates

- January Prints in Progress

- January Prints in Progress (Part II)

- January Prints in Progress (Part III)

- January Prints in Progress (Part IV)

- Framed Hapto Cone Art

- Ampersand Framed Print

- Speedball Brayer Holder

Whew! If you read all of those (or even just some of them) you might have some insight into my process. If not, feel free to come to Maker Faire Milwaukee and ask some questions!