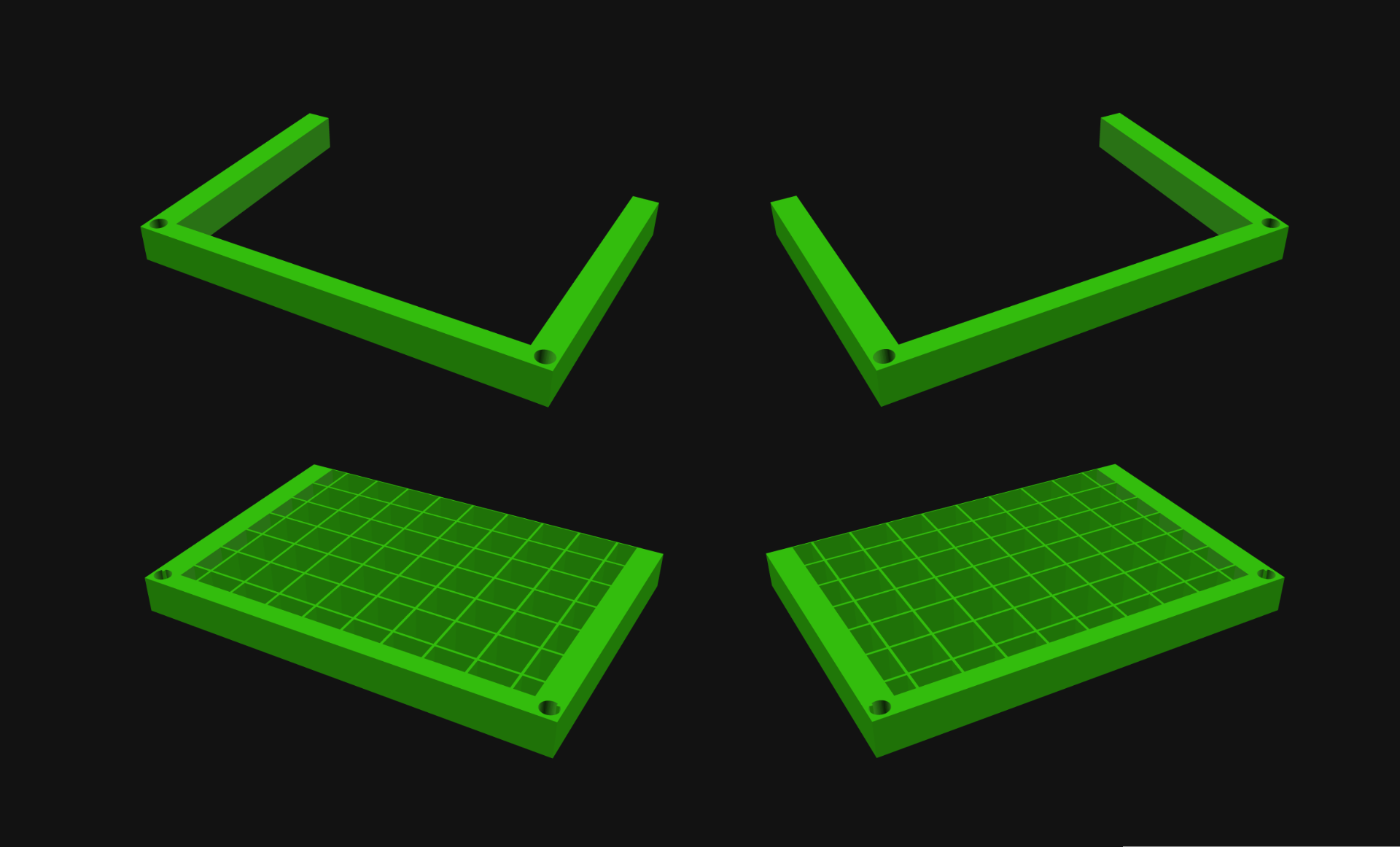

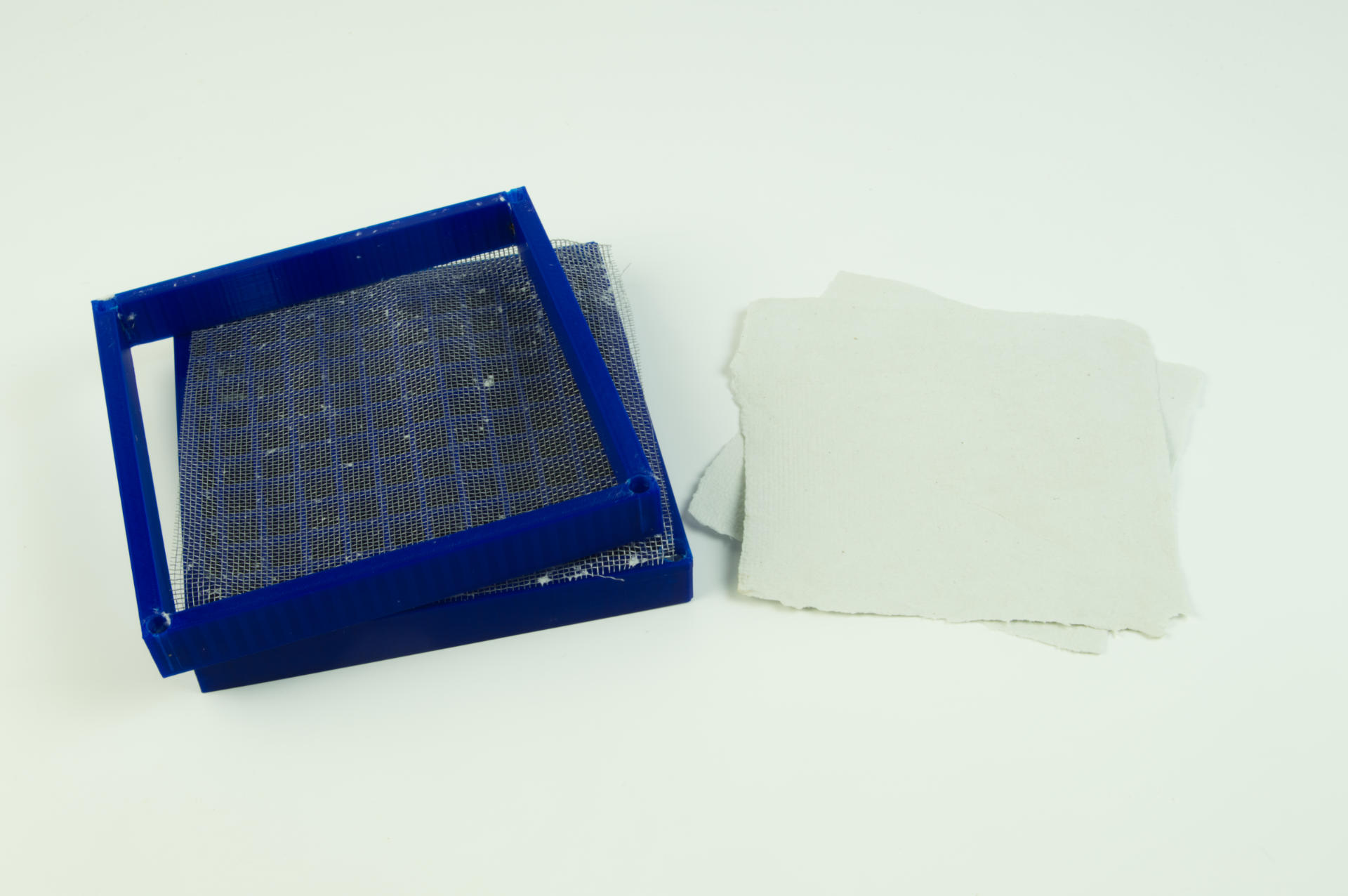

If you read the previous post you saw the mould and deckle I made, and the start of the process of making paper using the mould and deckle. Well, once the paper dries it looks quite different!

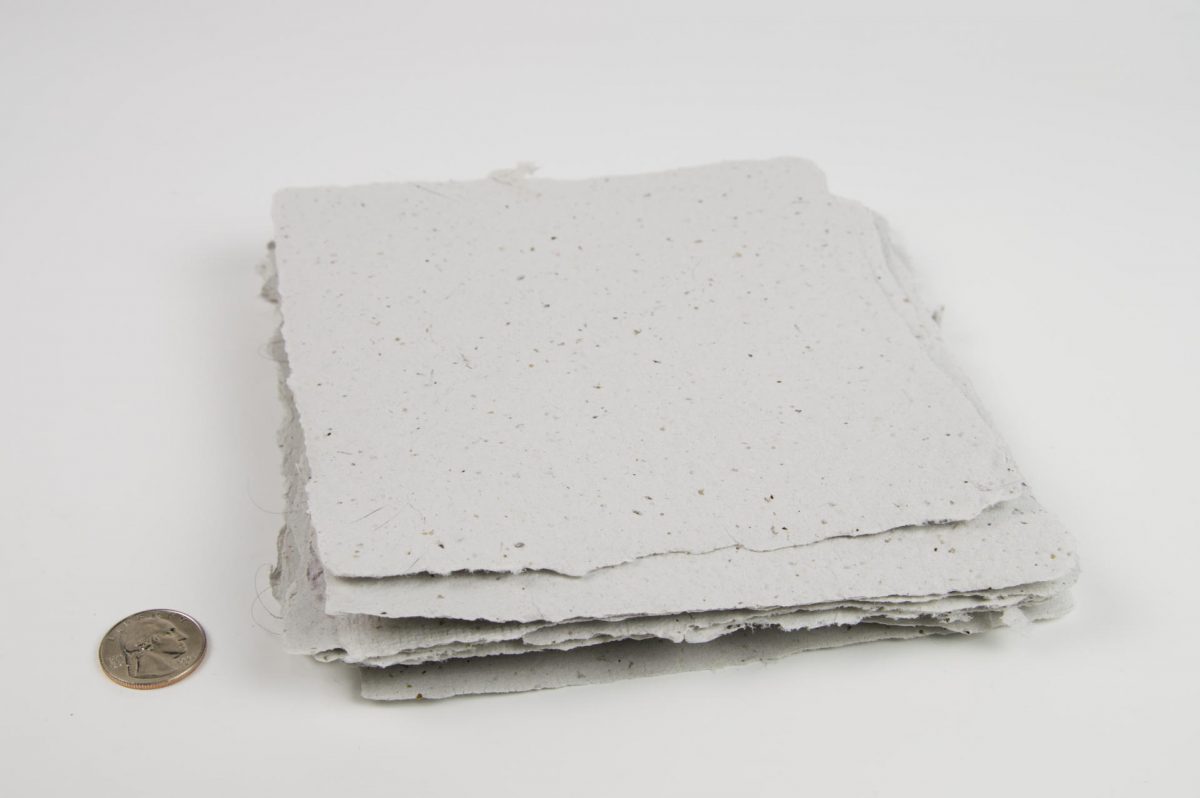

Here’s a stack after the pieces have dried. They are not exactly flat, as they curl up while drying. I couch them onto cut up pieces of an old bed sheet. I don’t press them when they are wet, I just let them air dry while laying flat, which takes about a day or so.

(Most people will tell you to press the paper when wet to remove the water and to flatten it, but I just sort of do it the way I’m doing it and so far it seems to be working fine.)

Once the sheets are fully dry that’s when I press them. I put each piece between a sheet of 3mm thick Baltic Birch plywood and then put the stack between two steel plates in a hydraulic press. (Here’s a press similar to the one I have.)

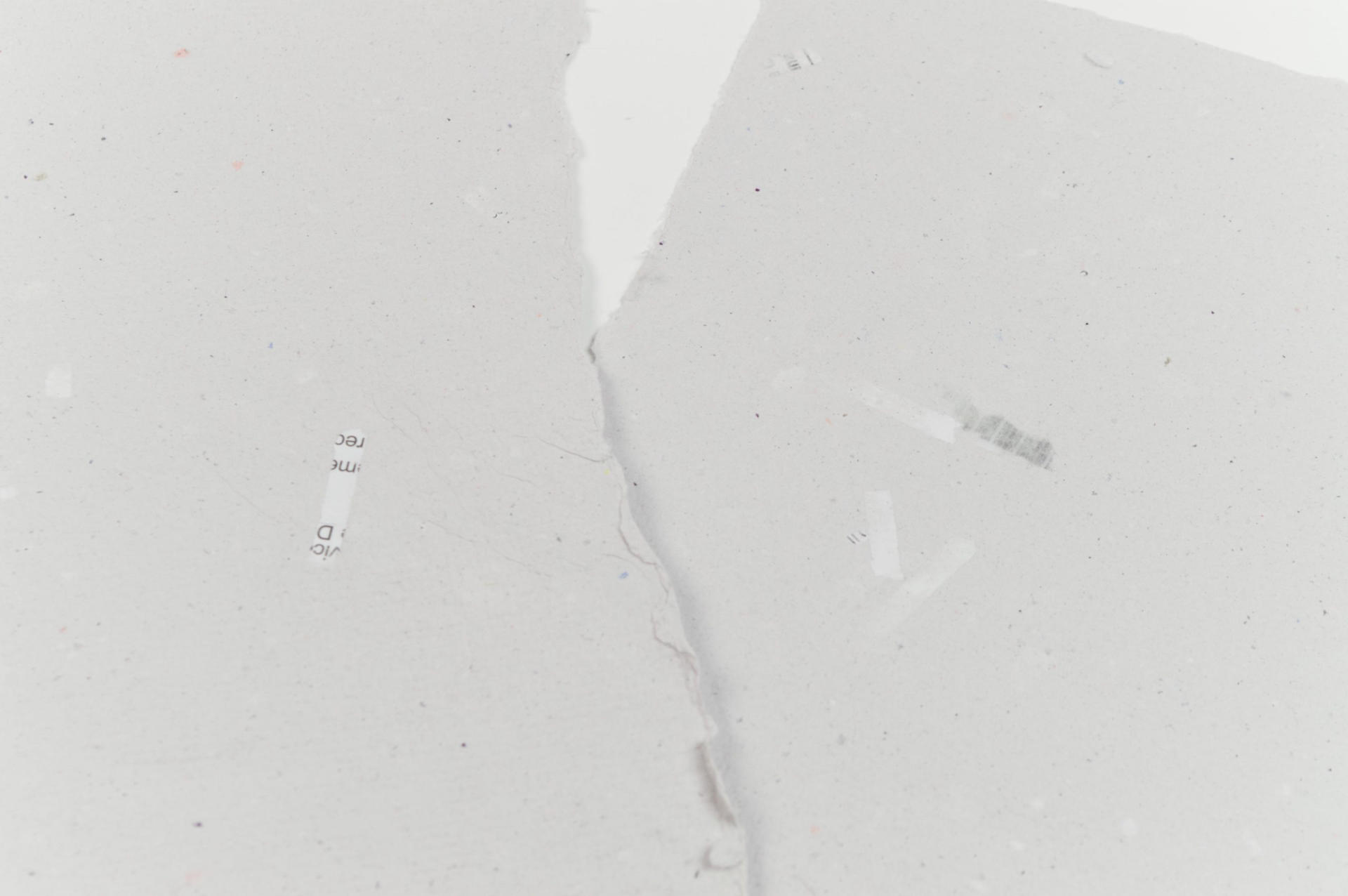

I’m still experimenting with the right amount of pressure. If I totally crank the press down hard I can get some very flat (and sometimes very thin) paper. One batch was actually a bit too thin! This batch is a bit thicker (since it was made better) but I also didn’t apply quite as much pressure, so it would retain some of the texture. Either way, one side is going to be much smoother (the side that dried face up) and the side that was against the bed sheet will have some texture to it.

Wait, bed sheets? Yeah, this is all pretty DIY, and I’m mostly using materials I have available and not purchasing a bunch of stuff. As I mentioned in the mould and deckle post I am using old window screen material because I have a bunch of it.

To make the pulp I am using paper shreds create by our home paper shredder. I’m making sure I don’t shred any envelopes with plastic windows or other strange matter (though my first batch did contain plastic!) The paper is never white because the ink/toner/whatever from the paper mixes with the water and pulp and turns it gray, which is fine. I do plan to experiment with some colorants. If you notice the brown speckles in this batch that comes from a bunch of dried up leaves I harvested from the garden. I crunched them up and added them to the pulp when blending it. I think it adds some nice character to the final product.

I was able to make a total of 16 sheets on the attempt, which isn’t bad, as I am somewhat limited in space. I’m starting to get to the point where I know how much pulp and water to use and how much it will make, so that’s good. I should probably measure things and write it down but at this point I’m still just screwing around to see what works and what the outcome is… Stay Tuned!

Note: This post contains an Affiliate Link. Read More.