I was doing a video shoot with Ben Nelson for Brown Dog Gadgets last week and I noticed his Vinten tripod leg had an issue staying locked in place… Seems one of the leg lock pieces had broke in half. It seemed liked a perfect reason to fire up OpenSCAD and get the 3D printer spitting out a new part.

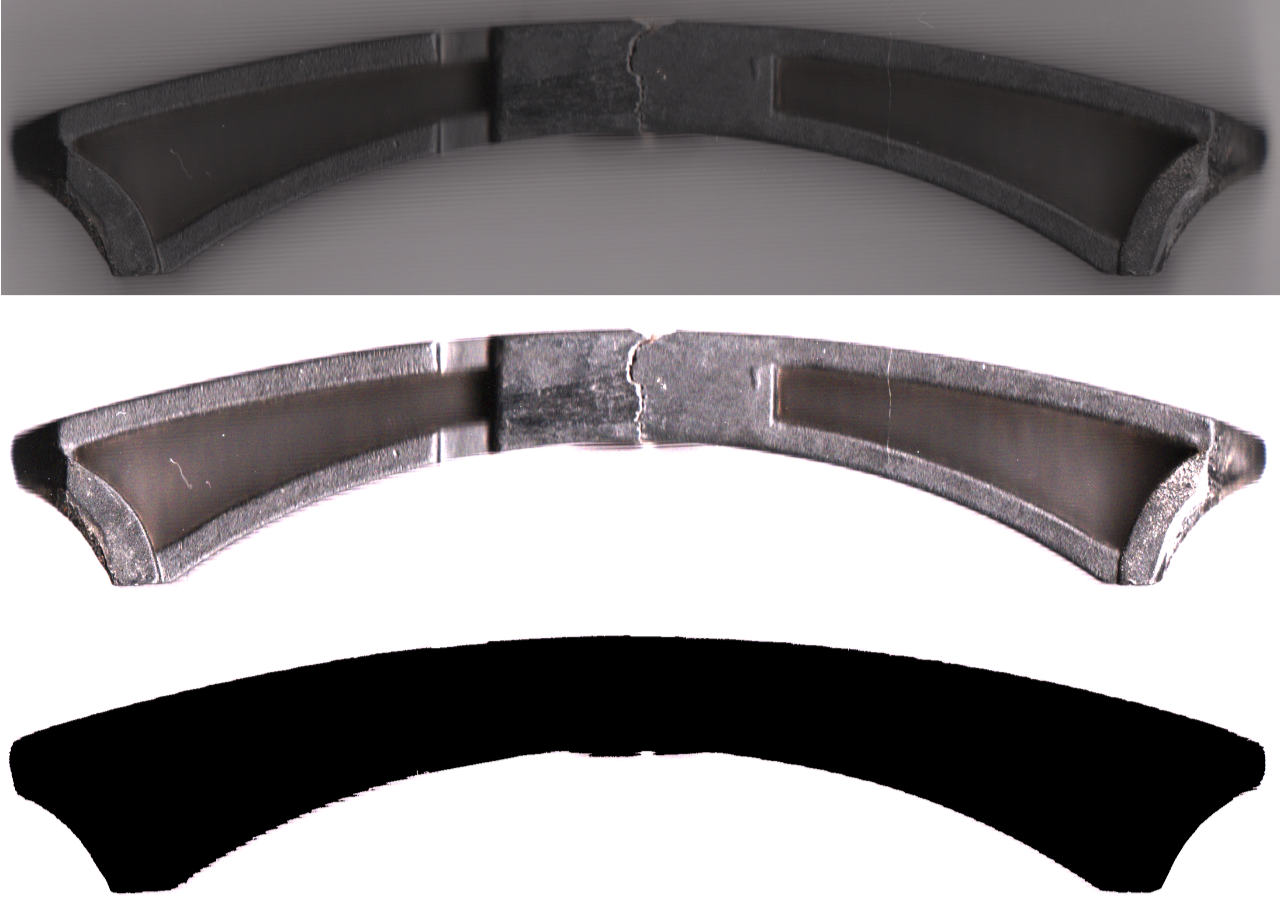

In the photo above you can see the new part in silver, and the two original parts on the other legs, in black.

It took two prints to get an acceptable fit. The first was a little too wide and wouldn’t quite fit in place. I tweaked the file just a bit and the second version worked well. I’ll walk through the process a bit below.

For an organic shape like this I usually start by putting it on a desktop scanner to get the profile. This one is curvy, and I’m not big on drawing curves in OpenSCAD, but I am big on scanning in an object and then tracing it in Inkscape. I did a few scans and even then I edited the image a bit to adjust the contrast.

I import the images into Inkscape, each layered directly on top of each other, then add another layer on top of that to do the drawing. I can then easily switch out the image below and compare things. For a symmetrical drawing like this I really just need to draw half of it, then I just dupe and flip to make the other half and combine them into one.

Once I have a vector file created I export that and then import it into an OpenSCAD file where I can extrude it changing it from a 2D shape to a 3D shape. Creating a solid object is the goal. Once I’ve got a solid object I can start knocking holes in it and adding angles by subtracting with various shapes. (The reddish parts are all subtractions or differences from the main piece.)

And yes, the above image does appear to be some sort of special forces TIE Fighter from the Star Wars universe.

Here’s our final piece, ready to be rendered, sliced, and printed. The original part had some pockets on the top and bottom, but since they were not required for functionality I left them out.

Ben installed it and briefly tested it and it seemed to work, though time will tell if it holds up under stress. (Also, this one is PLA so if he leaves the tripod in a hot car, it might soften and fail.) I’ll probably print a few more for him to keep in the tripod bag in case this one does fail in the field.

If you want to print one of these, you can grab the file from Vinten Tripod Leg Lock and have fun!