Back in December I heard about the Shaper Trace and ordered one immediately. I normally don’t order products immediately but a few client payments all came in at the same time and I needed to spend something on new tools before the end of the year, so the Shaper Trace was it.

I am no stranger to using the the Image Trace in Adobe Illustrator or Trace Bitmap in Inkscape to convert images into vector artwork. I’ve also uses a desktop scanner dozens of times to scan an actual object or a drawing, and convert that to vector lines so I can use it in various ways. The Shaper Trace streamlines that process and makes it (in theory) as simple as taking a photo on your mobile device and letting a web site (not a locally installed app) covert it for you.

Does it work? Yes, it does work. Is it perfect? No. I mean, nothing is perfect, but it is quick and easy and as I’ve mentioned before the easier a process is the more likely I am to do it. If it takes me between 5 and 10 minutes to scan something, bring it into Inkscape, and then convert it to lines that’s not bad. But… if I can take a photo with my phone, save the file, and have it in Inkscape as a vector file in less than 60 seconds? Well that’s pretty damn good. Shaper says “From Sketch to Vector in Seconds” and it’s kind of true.

Caleb wrote up a post on Makezine back in July. I dug around but didn’t find too many other posts about it. Some forum posts, and some promotional videos, but few longer write-ups.

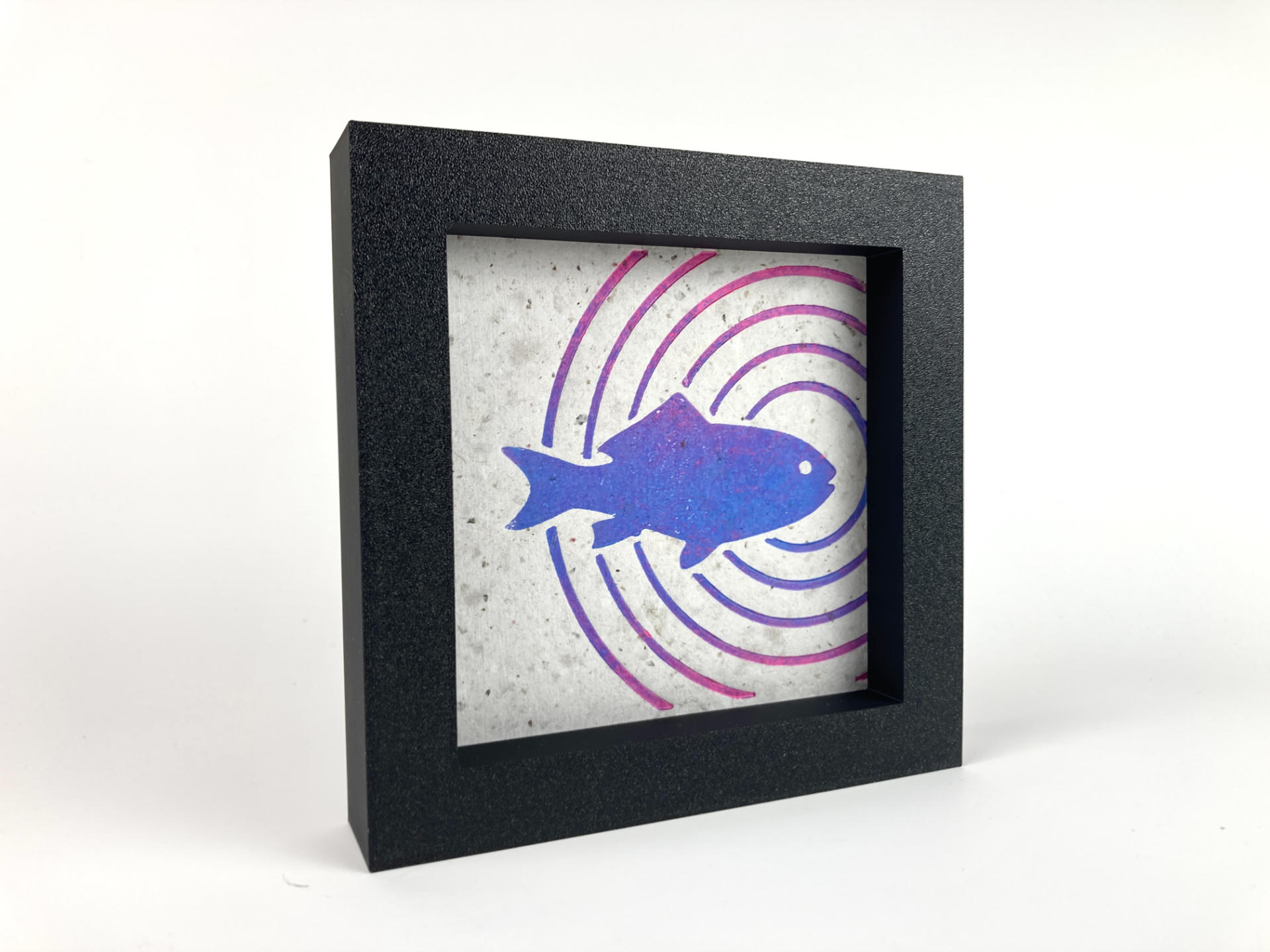

The idea that Shaper has is that you’ll use the Trace to capture a paper drawing, vectorize it, and then send it right to a laser cutter or CNC machine for cutting or etching, maybe with some minimal design work along the way. They show someone tracing the outline of a tool and then cutting out a pocket for the tool. I tried doing a few traces of objects and I just wasn’t pleased with the results. I’ve been using calipers and measuring things for CAD for a decade now, and I just feel like that’s a lot more accurate for my needs.

So what is this thing? It’s just a frame? Well, it’s a frame and a web app (not a mobile app) that captures an image and gives you a vector file. Note that you don’t have to perfectly align the camera directly above the drawing as the frame will compensate for angles. That’s nice. (In fact it seems that it might work better if you do shoot from a slight angle.) Each frame is the same on the front (more on that later) but on the back is a unique QR code associated to that frame, and you then register it to your account to use it. Want to share the frame with someone? You’ll need to use one account. The frame itself is just a hunk of plastic with no magic inside. And I mentioned the web app, right? A lot of people were really upset there is no local app that can work without an Internet connection. (I’d like both options, please!)

So basically you are paying a (one-time) fee to get access to an application running on the Shaper Tools web site that works with the frame. For $99 USD I guess I’m okay with that. (I will probably never buy a $2,900 USD Shaper Origin, and $99 is probably the upper limit I’d pay for a device like the Trace. It could honestly be a bit cheaper if you ask me.)

Since this post is titled “Using the Shaper Trace” I should probably explain how I use it.

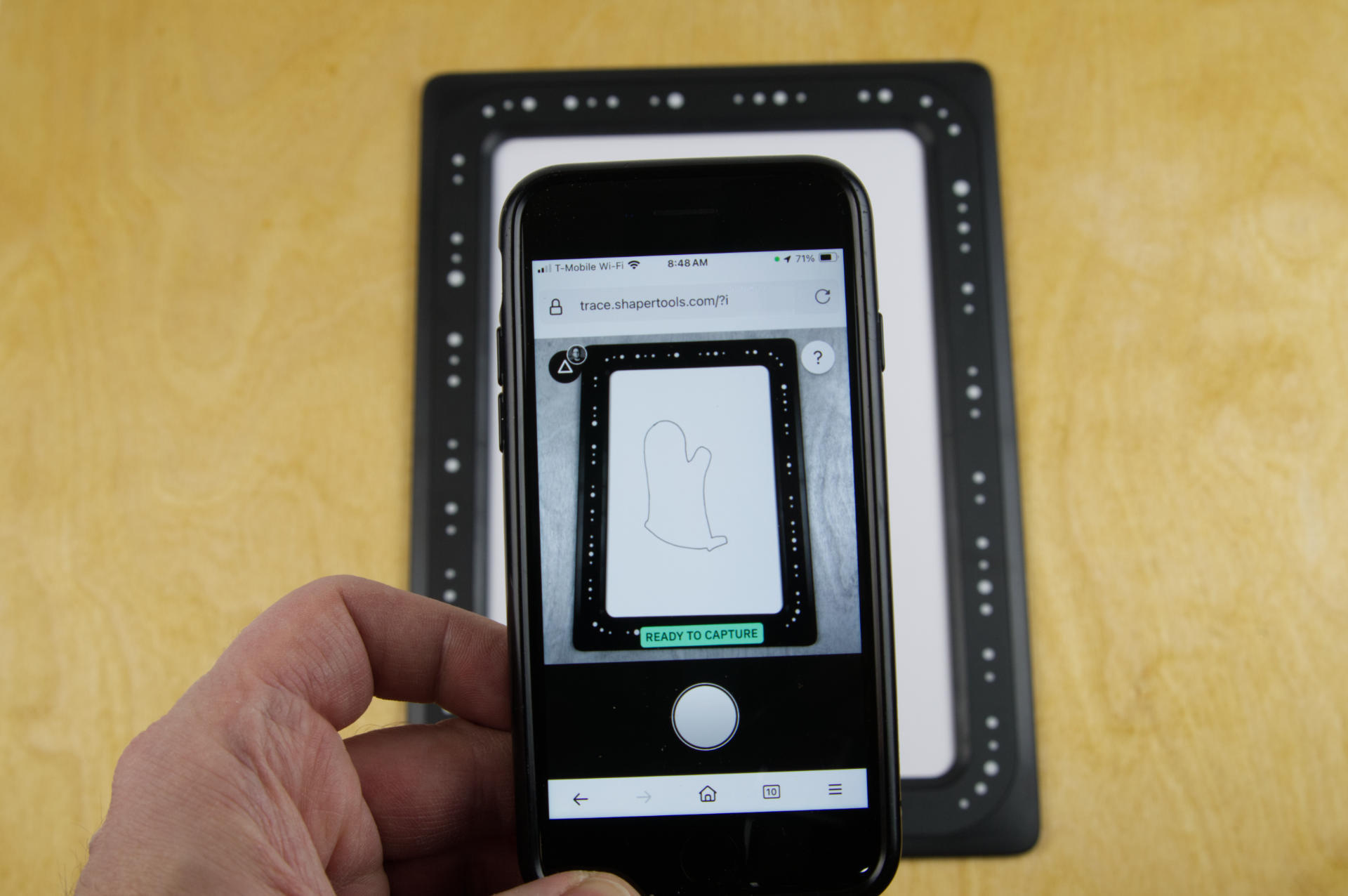

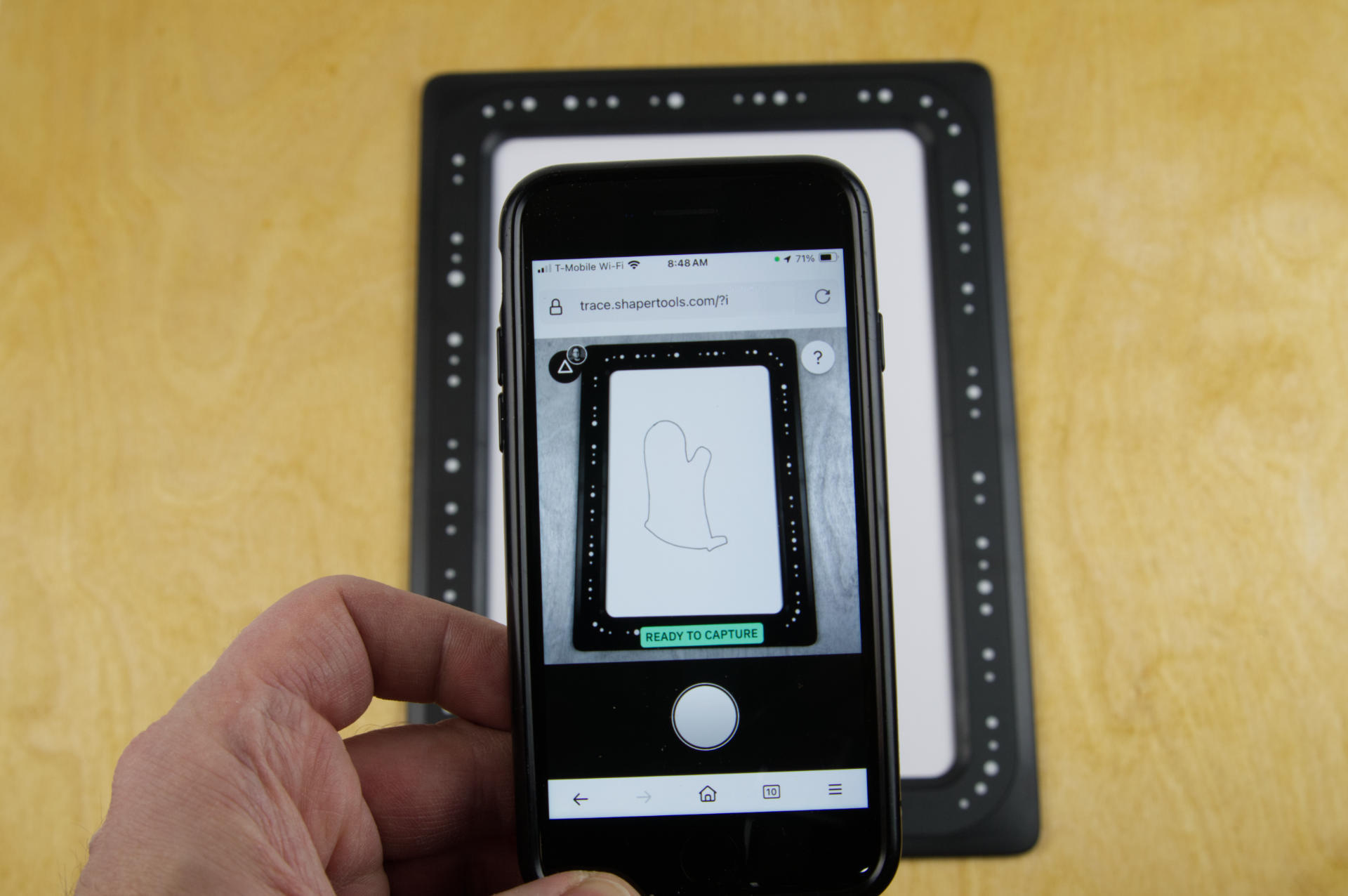

Look, I made a drawing! It’s an oven mitt, in case you couldn’t tell…

I use my mobile device to load the web site and capture the drawing by placing it within the Trace frame.

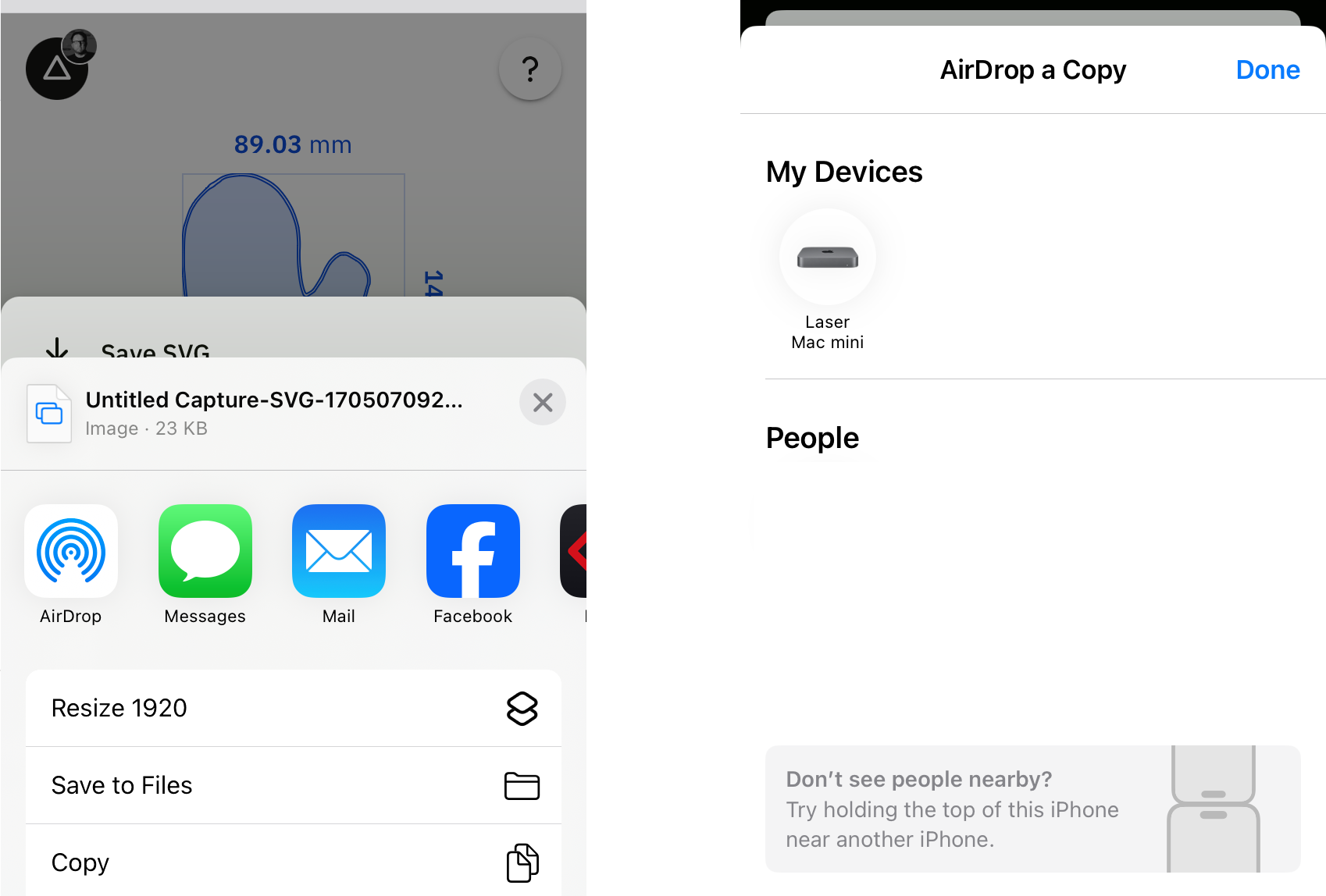

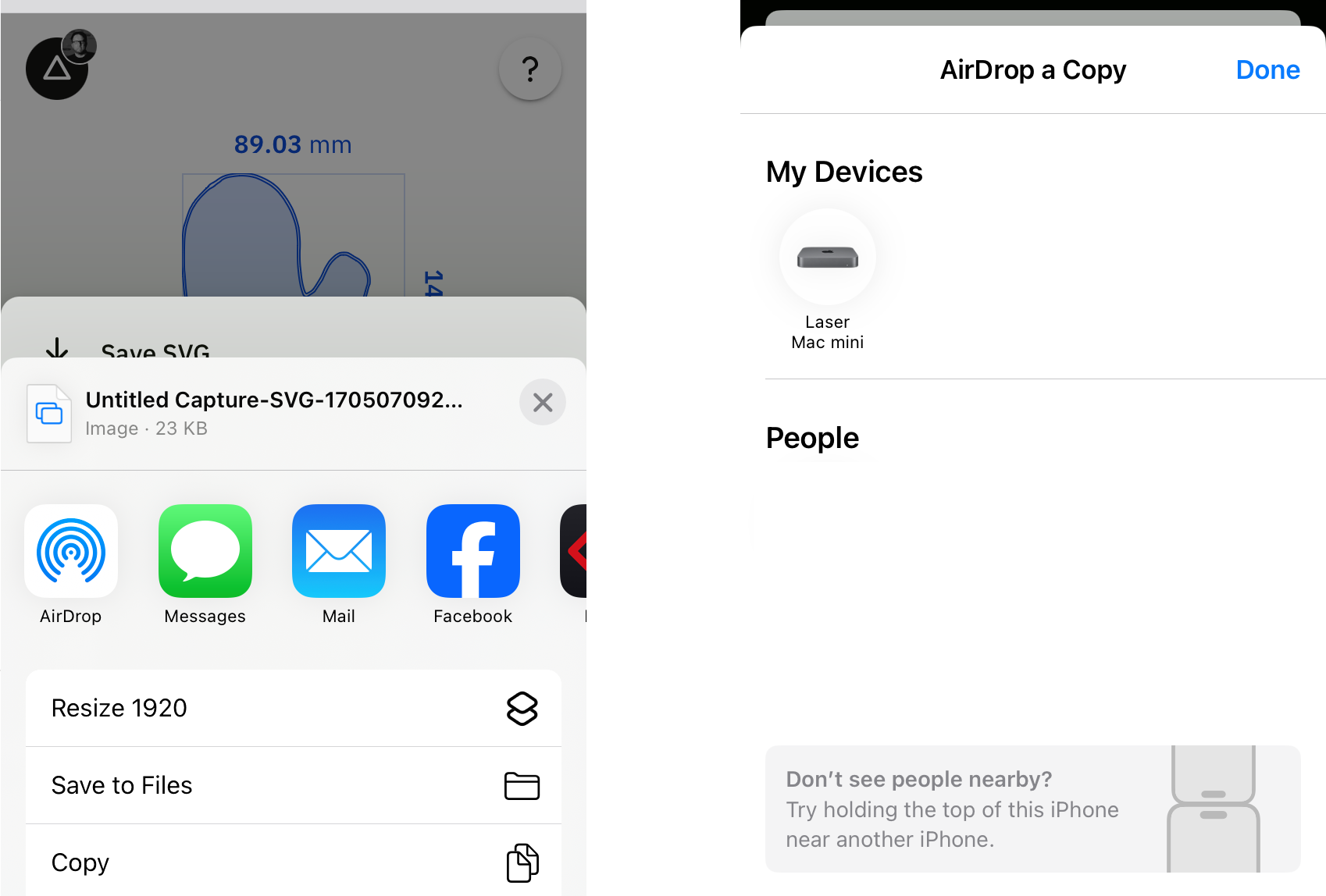

The drawing is converted to vector and you can choose two options, outlines and centerline. I pretty much always use outlines since I’ve create my drawings with the idea that the outside of the line is what I want.

I save the SVG, either to my phone, a drive accessible to my computer(s), or in my case I use AirDrop to send it directly to my computer.

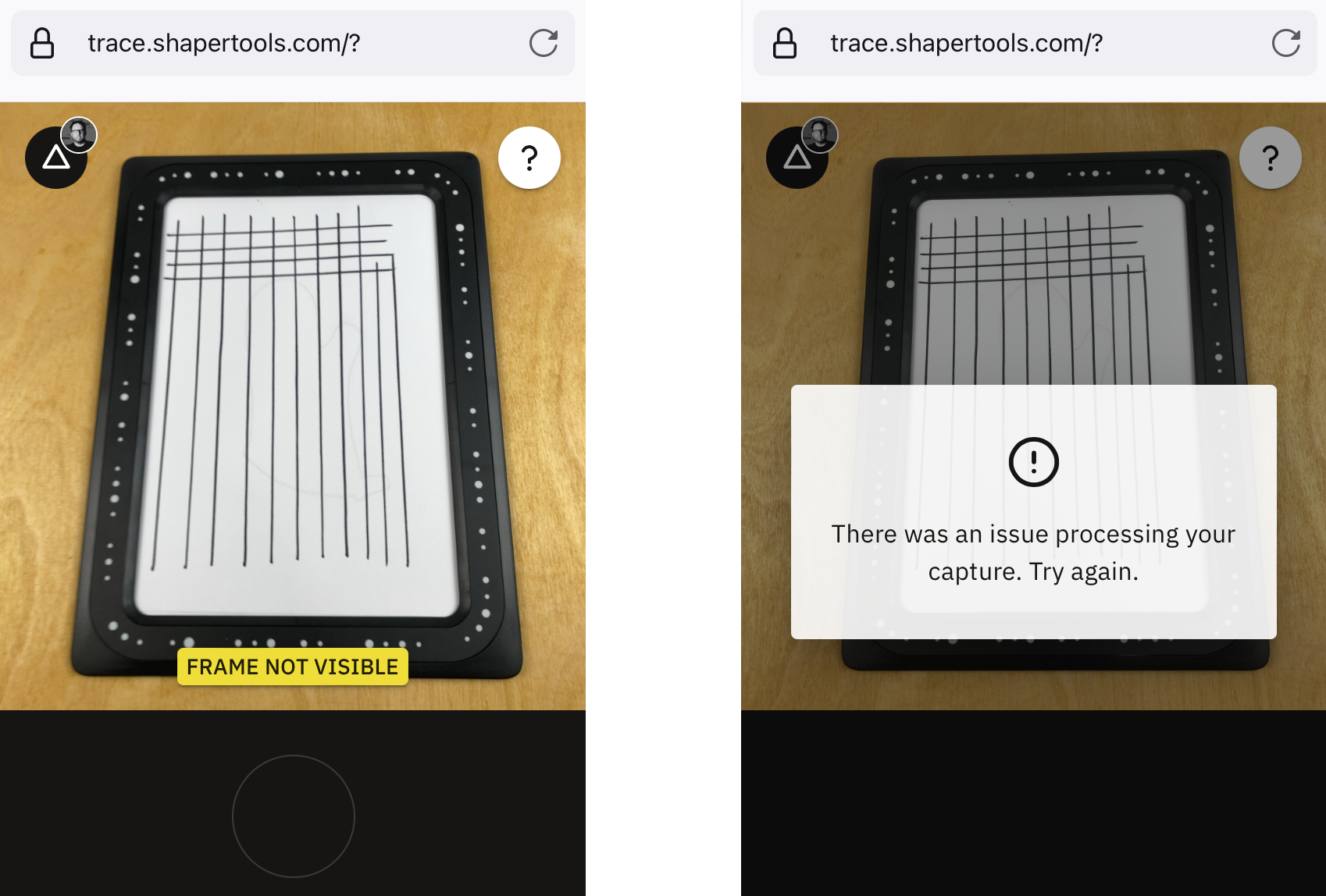

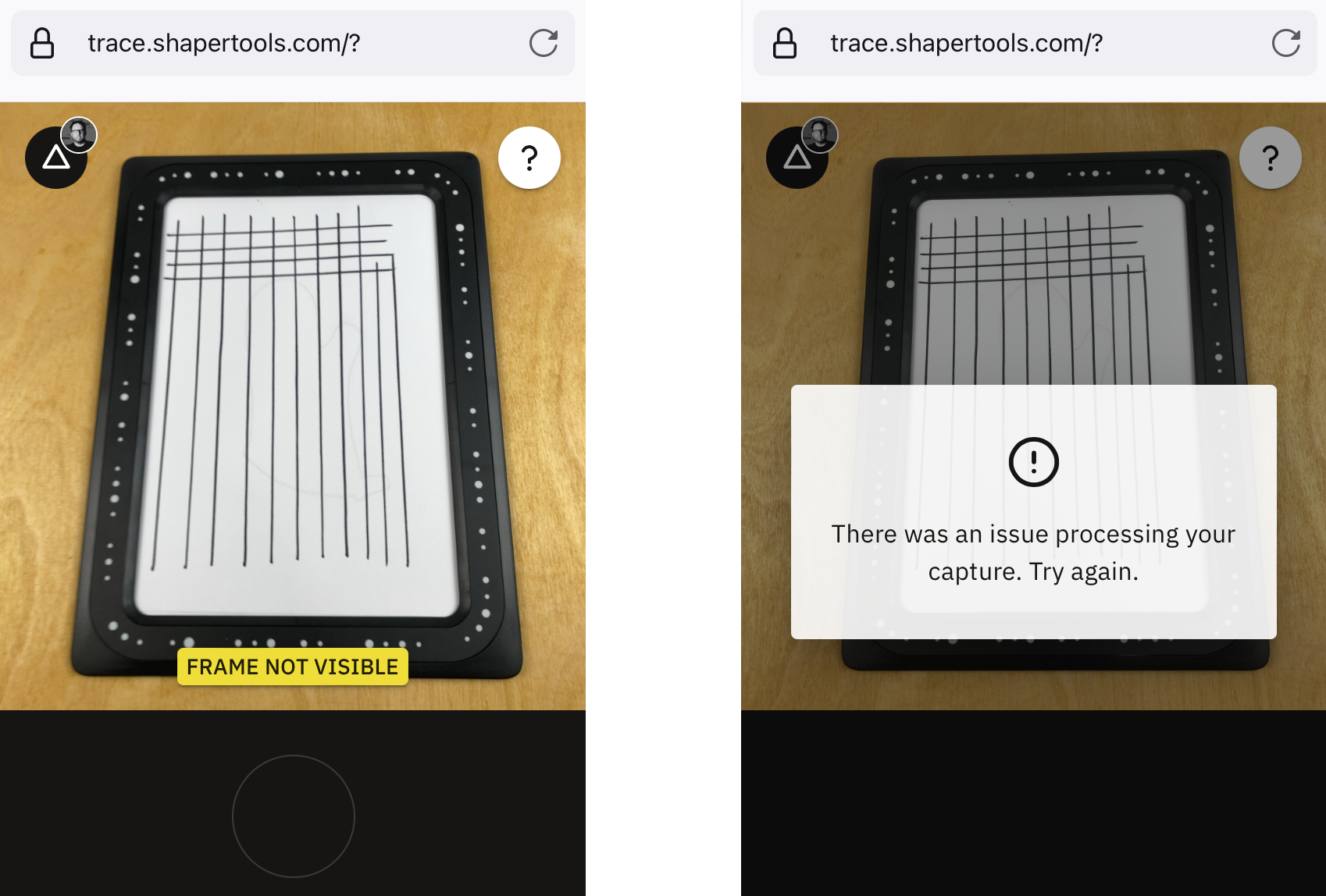

I think I’ve digitized a few dozen drawings with no issues. I do tend to place the Trace and drawing in good lighting and get a nice clear shot of it with the camera. Still, things can go wrong. Here’s an error I got one day. I think I closed the web page, reopened it, and tried again and it was fine. Not sure if the issue was their servers, my browser, or something else. (And of course you do need an Internet connection for it to work.)

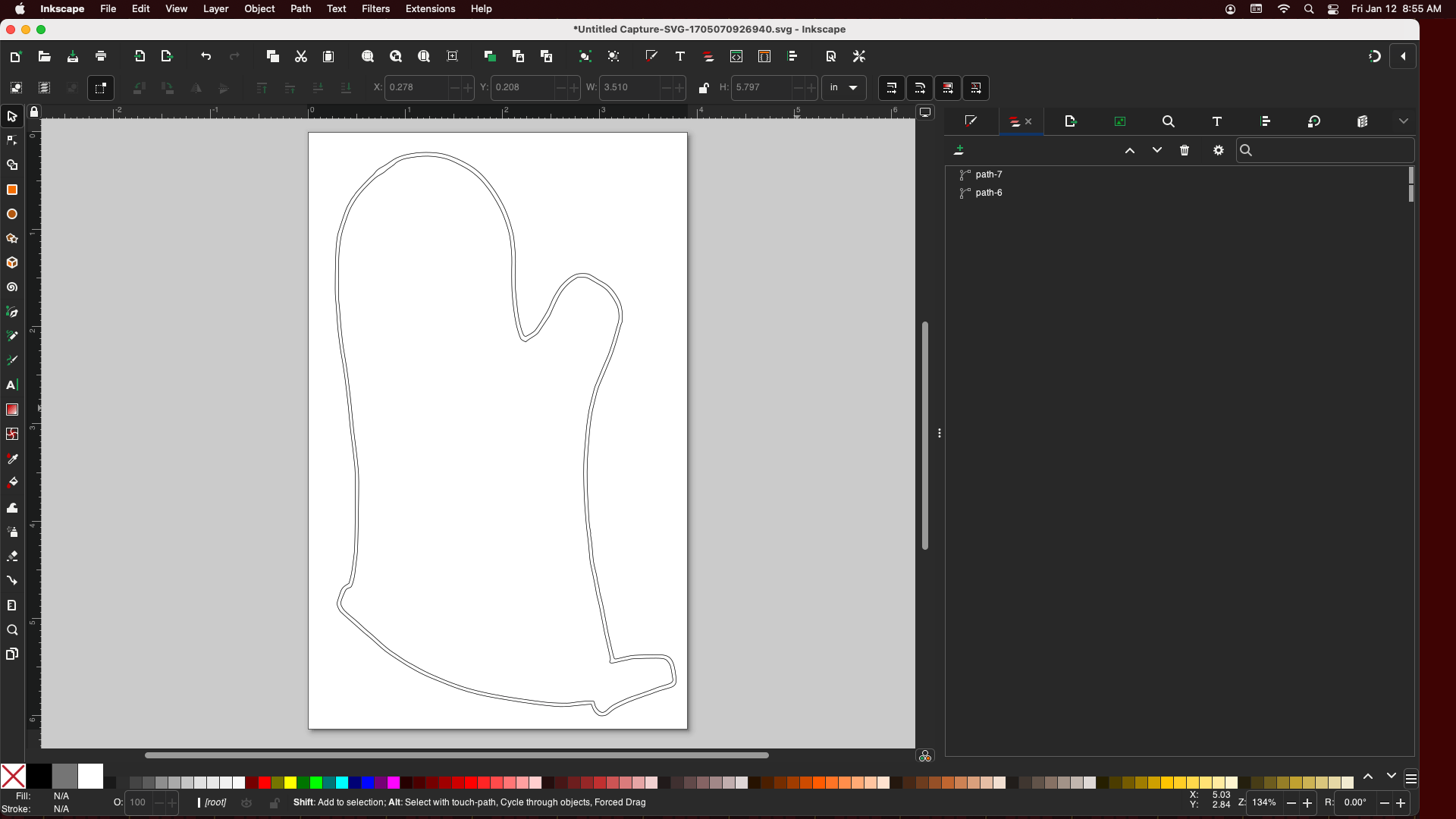

I then sit down at the computer and open the saved file in Inkscape where I can do whatever I want with it. (I won’t get into the specifics of editing a vector file, preparing it for use with whatever machine you might be using, but hopefully you get the idea. It’s that simple.)

But Wait! What if you are at work, and your Trace is at home, and you really want to use it? Well, just use a copy. As I mentioned, all the Trace fronts are the same, so the web app doesn’t care what Trace you are using, as long as you have an account and it sees a Trace-like thing, it works just fine.

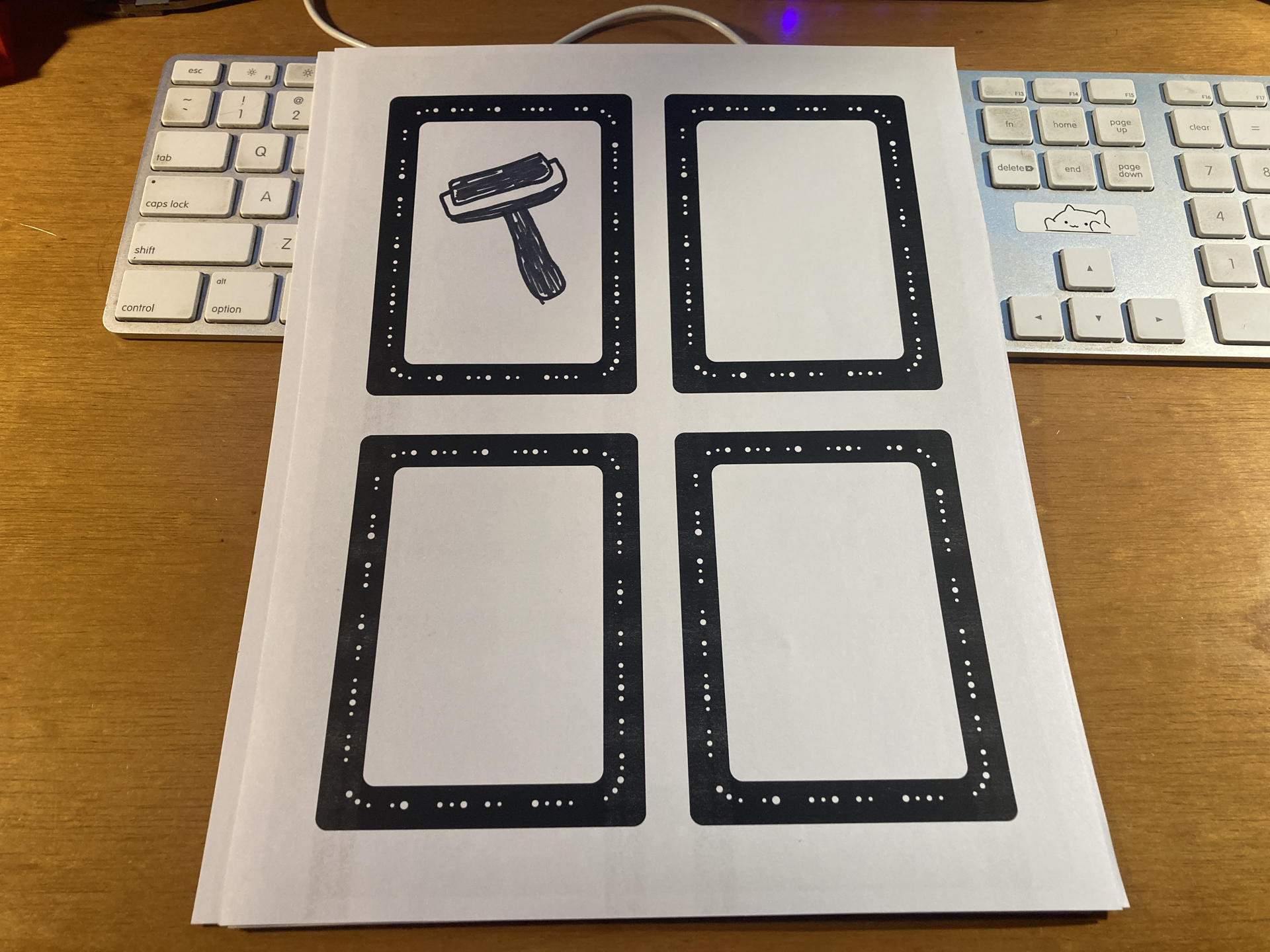

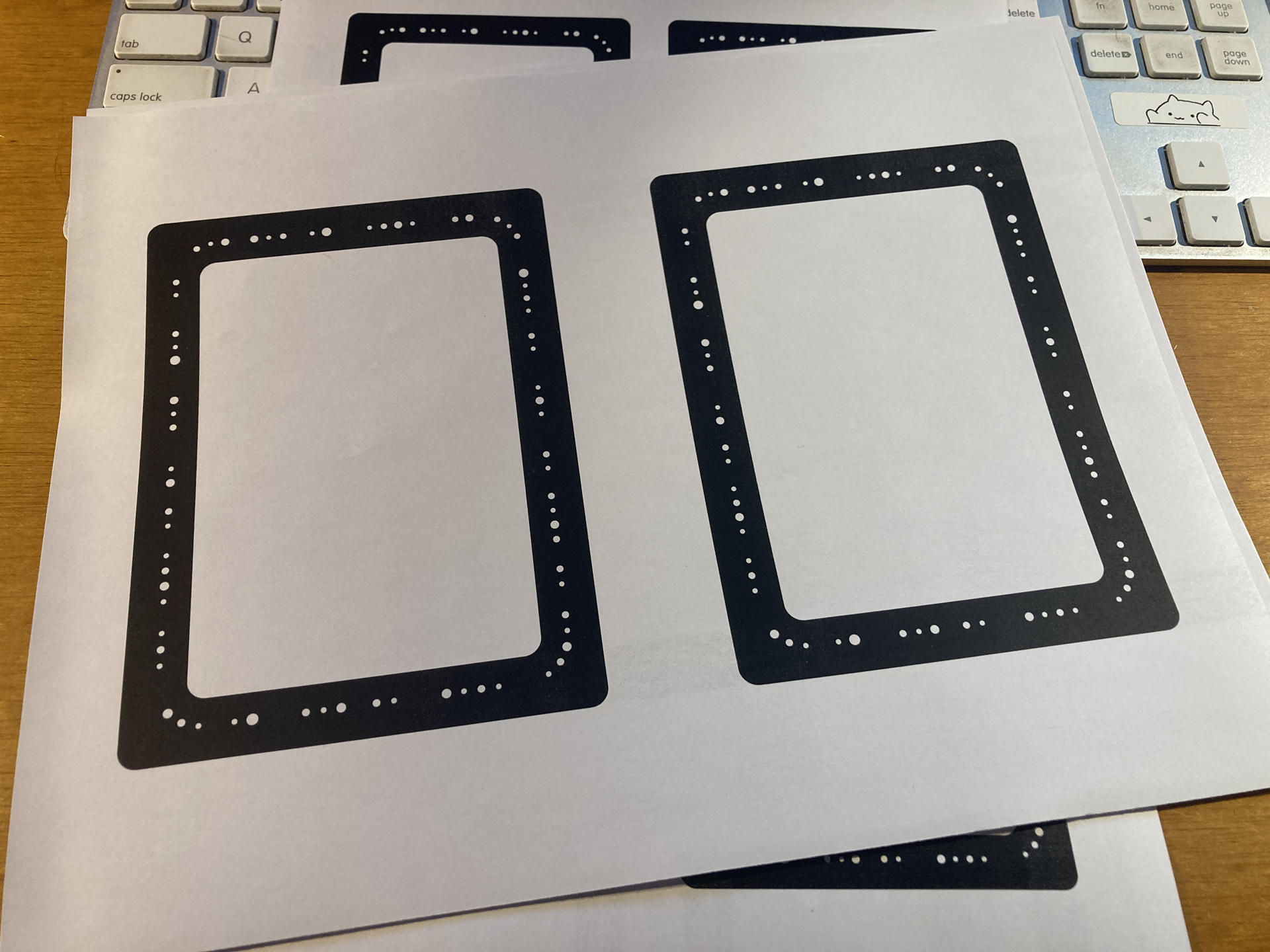

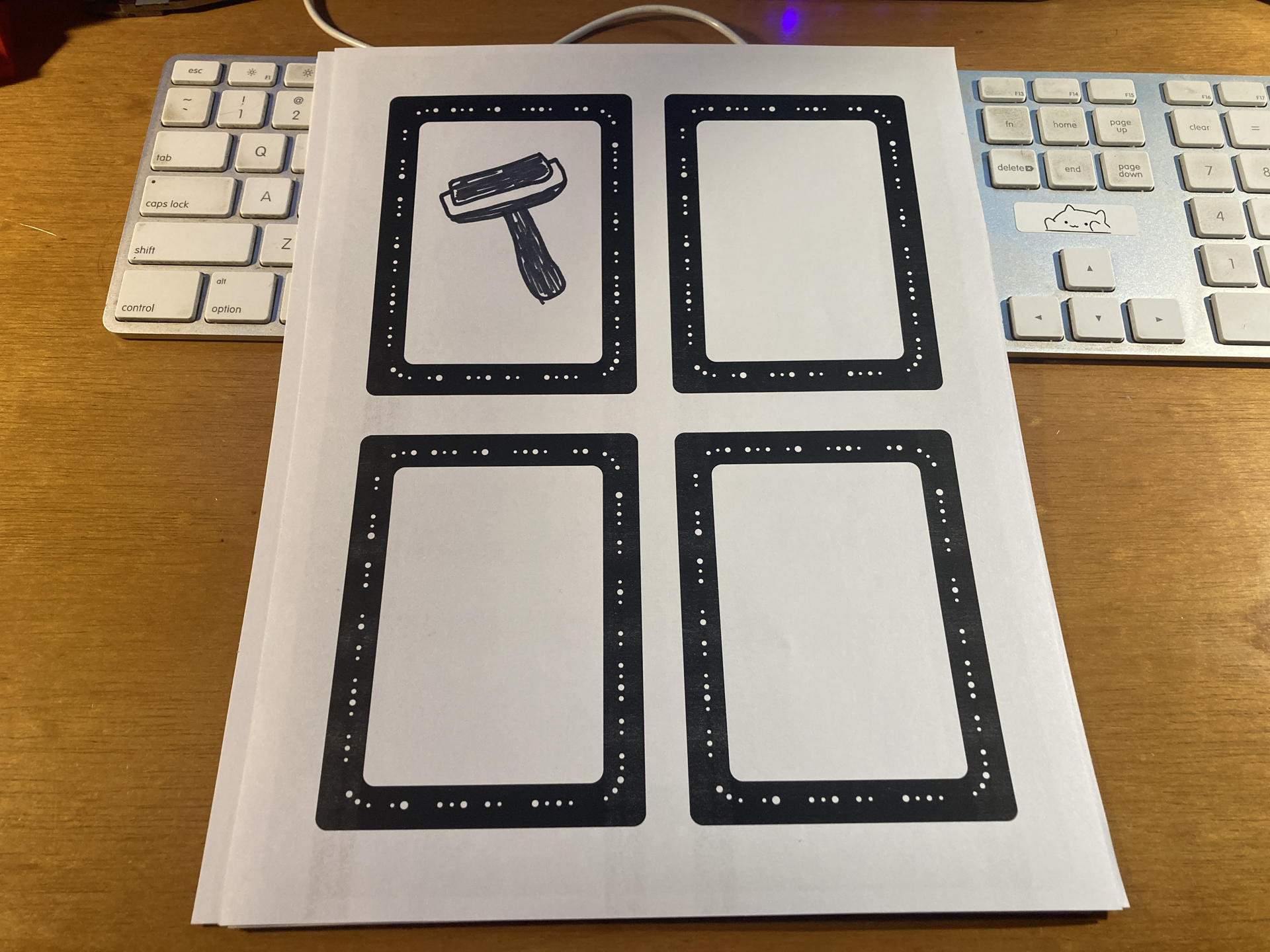

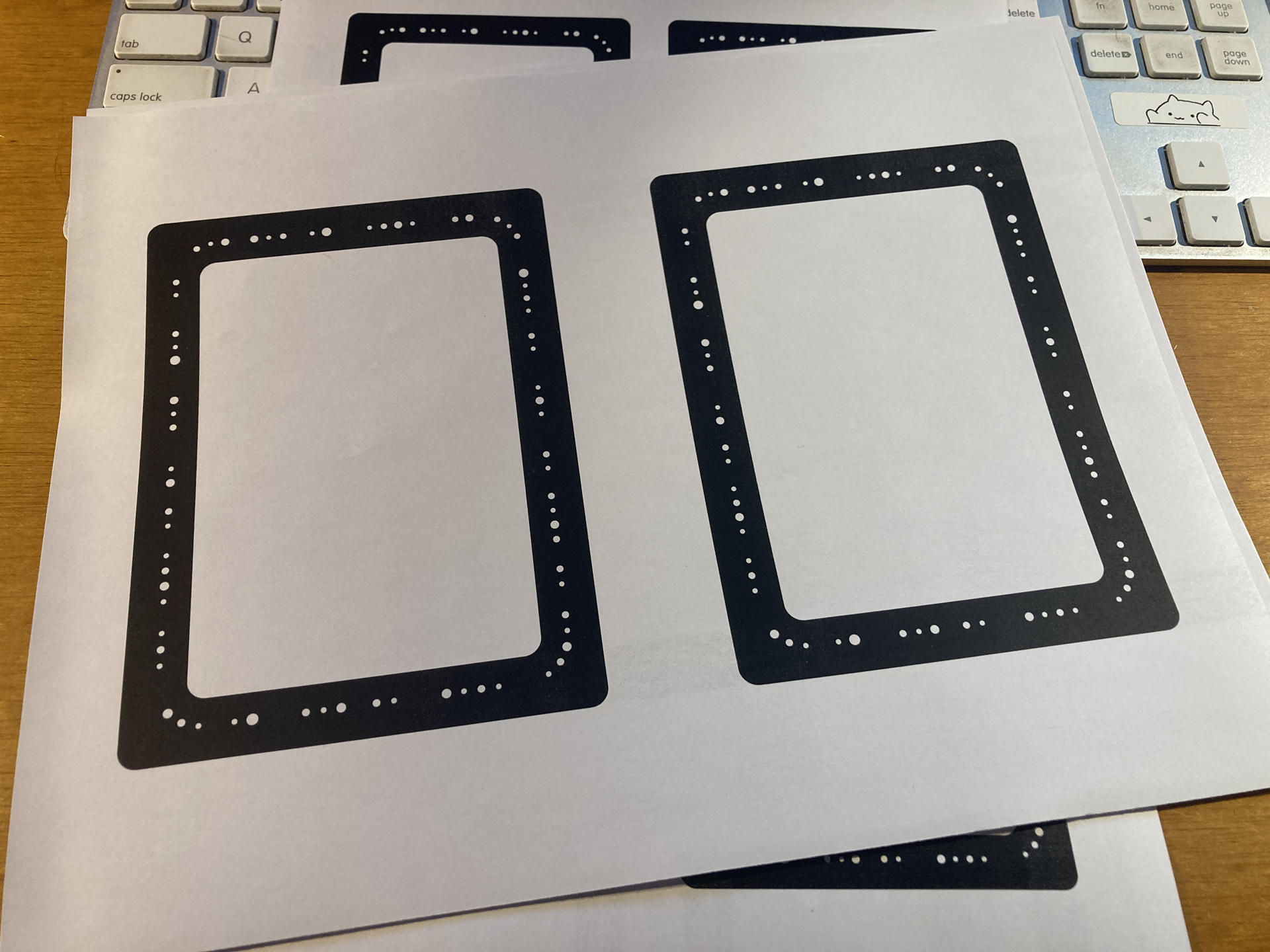

Here’s a printed out copy of the Trace frame. It’s not even my Trace, I grabbed the image from the Shaper web site and printed it on the copier at work. Neat! (Oh, some other people noticed this as well.)

Even better, you can print smaller ones. Here’s a letter size sheet of paper with four Trace frames. You can basically make them any size you want to work with the size of drawing you want…

This is really cool because if I wanted to do a small drawing with the actual Trace frame I’d still need to scan an entire sheet of paper and the drawing might be quite small on it, so this sort of lets you play with the resolution, which can make a different if you are drawing by hand, and lets you play with different pens and line width as well. This basically eliminates the need to even use the actual Shaper Trace frame.

So the Trace is an interesting tool, and I can totally see how someone might get one and it may not do what they want, and I think I felt that way at first, but the more I use it the more I am building a workflow around it, so that’s good. If you’ve got any questions about the Shaper Trace let me know!