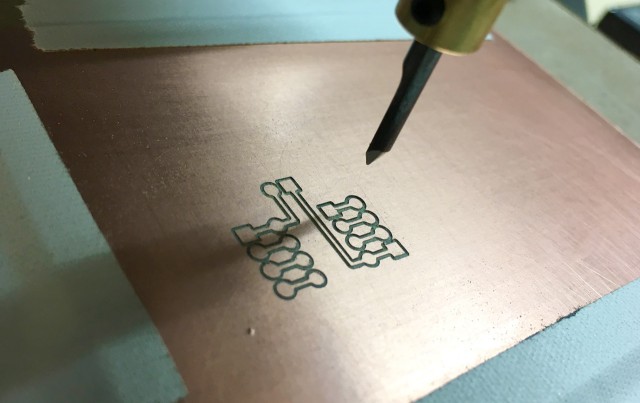

I’m still (slowly) working through using the Little CNC Milling Machine. I (mostly) successfully milled a PCB, but before I did that I managed to grab a piece of HDPE and mill something.

I started with a vector file of one of the Milwaukee Makerspace logos, taking just the (“new style”) helmet and I brought that into MakerCAM to create the cutting paths. I created a pocket for the inside part, and used a profile for the cut to remove the part from the material. Since I was just using one bit I exported both jobs into one file so it could run it all at once, since I didn’t need to change tools.

I then used GrblController to connect to the machine and send the G-code needed to cut the part. I’m still not convinced everything is working as it should be, because either I keep doing the math wrong (possible) or the machine seems to step down farther than I expect it to. More experimentation is needed.

I secure the HDPE piece down to a piece of MDF that is attached to the bed of the machine. The bed is a piece of Aluminum and I’d rather dig into the MDF if I go too deep than carve into the Aluminum. I’m still not totally happy with what I’ve got going on with the bed, but I’ll work on that another time.

Let the milling begin! Again, it seems like the machine was going a bit deeper than I estimated. I’ll have to work on getting the speeds & feeds more dialed in, but that’s pretty much a true statement with every CNC machine & material combo, right?

Here’s our final piece. I made the pocket deep enough that you can actually see some light coming through. Nice! There’s one little bad spot around the outside cut. I should have added tabs to hold the piece down, since it shifted a little when it was finally cut all the way through and the bit took a bite out of the material.

In a way, this is an update to my original HDPE milling experiment, which is fitting, because I used a Shapeoko the first time. Now, when the Shapeoko was first presented on Kickstarter it was presented as a CNC mill that would cost around $300. Well, it ended up casting quite a bit more, but six years later we’ve got the (under) $300 CNC milling machine you can have at home. Yes, the work area is a little small, but we’re going to rectify that in the future.