When I first launched Gallery 69 (a Free Little Art Gallery) I had this plan to add a light inside and have it solar powered. That never happened, but Dana offered me a set of battery powered holiday lights when winter came and I put it on the outside of the gallery so you could see it after 3:45pm when it started to get dark outside.

I would swap out a set of AA batteries every week or two depending on how long they would last and how often I would remember. I decided to revive the solar idea to power the lights. Here’s where I will add the disclaimer that I am terrible with calculating power requirements. Terrible. Too much maths for me. Anyway…

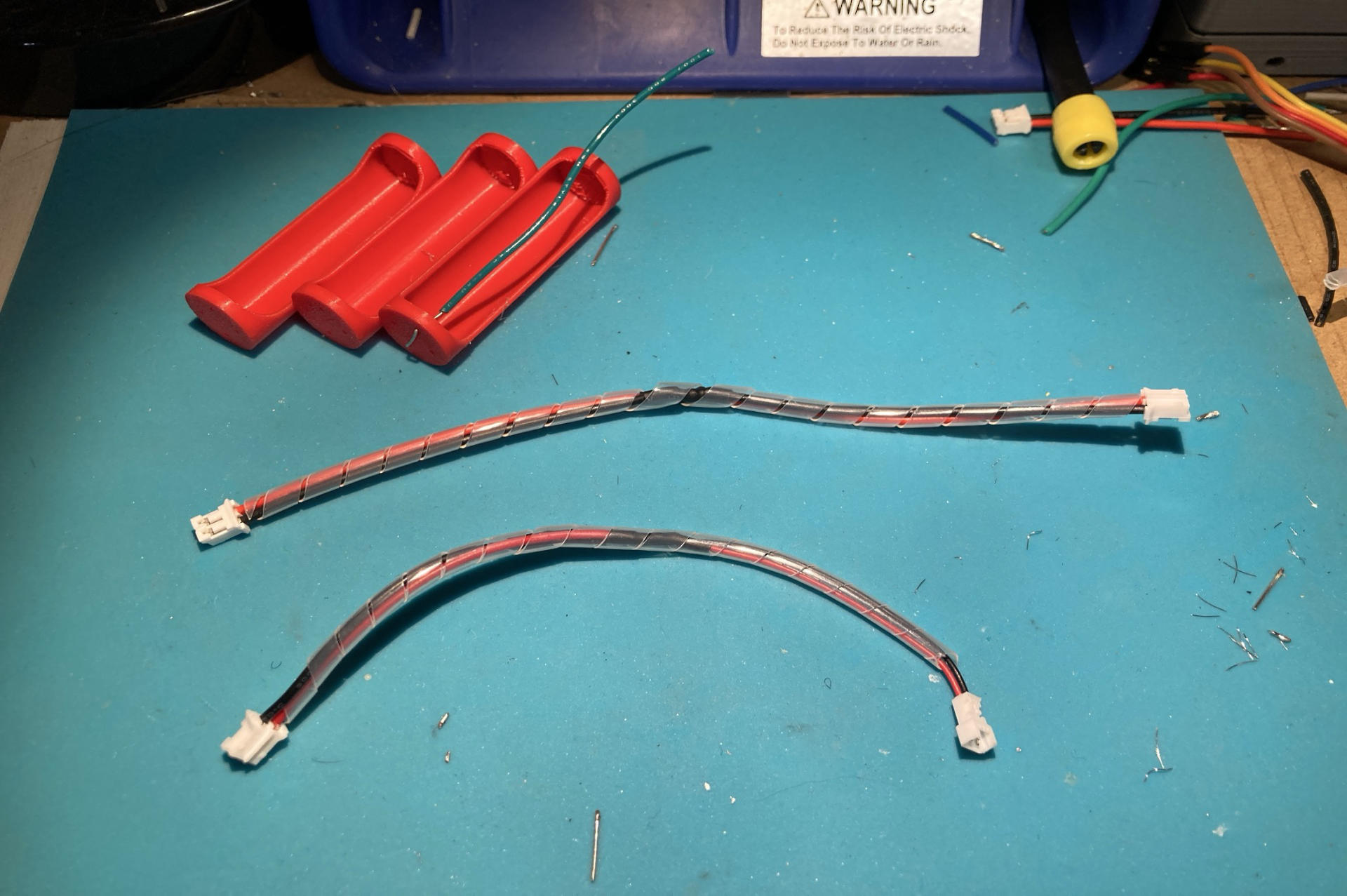

I had this Solar Panel from Brown Dog Gadgets which I wasn’t sure would work, but I had it so I figured I would start with that. I got these CN3065 Solar Charger Boards for cheap not expecting much. I also had my eye on an Adafruit solar charging board but they were out of stock, which seems to happen a lot with Adafruit. I grabbed a bunch of JST connectors as well.

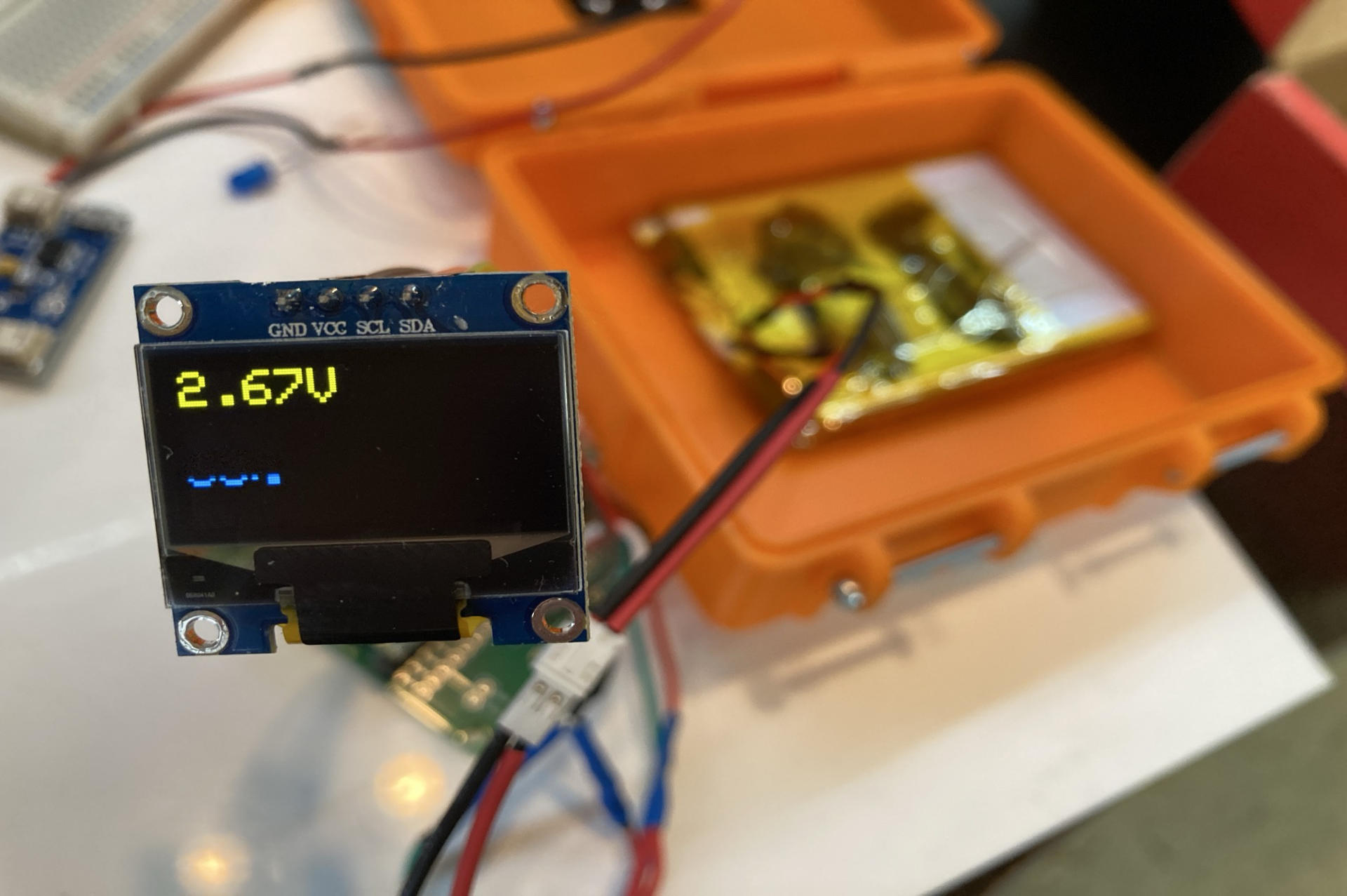

For the battery I tore apart an old USB power bank. It was probably 10+ years old but it seemed to still work so hey, I’m cheap. (Don’t worry, I still have at least a dozen working power banks.) I did do a bit of testing to see how long it go before the voltage dropped too low. That testing is part of another project still in the works. Anyway…

Remember when I was making Rugged Box Silicone Gasket Seals? Well, I printed a rugged box with a hole in the top, hot glued the solar panel to it, ran the wires through the hole, and then sealed the hole and wires with hot glue. (Somehow I have no photo of that.)

Okay, I needed to power the lights, which worked with 3 AA batteries, so I used these Customizable Dummy Battery(s). Originally I was going to print three, wire them up, and use that… Along the way I only used one to make contact with the negative connector then used alligator clips for the rest of the connections. This is one of those “I’ll test this” sort of things that is now somehow permanent.

Yeah, so somehow I threw all that together and it works. It’s messy, but it works. At first I thought it was not working. I’d turn it on, check it the next day and it would be “dead” but it would turn on again. Then at some point Dana gave me the box the lights came in and I realized it lights up for 8 hours and then turns off for 16 hours. So it was working just fine. After that I left it alone to do its thing. I did make sure I turned it on at 3:30pm in December so it would be running when it got dark out. They should stay lit until 11:30pm.

When I wrote “A solar project that actually works…” above it was mostly a joke. I thought it didn’t work, but it did work. Meanwhile I struggled with another solar project at the same time, which I now also have working. I didn’t want to say “My First Solar Project” because as a kid I connected a solar panel to a small fan I got from American Science and Surplus and was amazed it worked. (That was probably around 1981 or so…)

So yeah, I did this back in December but wanted to wait a bit to make sure it would keep working… and since it’s been two months I think it’s good. The panel gets some really nice direct sunlight in the afternoon and even with a bunch of cloudy gray days it’s kept running quite well.