I started riding more often in 2024 and was riding anywhere from 3 to 6 days a week but always solo. My old pal Matt mentioned a group ride called Scrappy Hour and described it as a “casual slow roll” ride, which sounded right for me because I don’t really go fast, I just cruise around.

So I joined Matt last October for my first real group ride, and it was fun and easy, so I did it again in December and while it was a little cold it wasn’t too bad. Matt couldn’t join in but my old pal Mike was there and I saw Nora (another Milwaukee person I know) again. Otherwise I really don’t know many people on the rides (yet) but that doesn’t really matter, it’s just about getting out and riding in a group.

The most recent ride (this past weekend) saw me and Matt, along with my neighbor Michael, meet up at Rocket Baby in Tosa to do a smaller group ride that meets up with the larger group. We met Meg and Paige there and the five of us biked down to Cathedral Square Park together. The roads are not very busy on a Sunday morning at 9am so it was pretty easy going, and mostly downhill!

I will say that the Tosa leg was not as much of a “slow roll” as the Bay View legs have been… I guess when you let people half your age lead it can go a bit faster. (Disclaimer: I’m not totally sure but I’d guess I’m one of the oldest people on these rides. Not that age matters but I’m not exactly in great shape like some people are.)

I made sure I would not be cold on this ride. I wore my winter boots and wool socks, balaclava, ski goggles, a scarf, and then two long sleeve shirts with two sweatshirts, and long underwear with insulated exercise pants. I also had my medium winter gloves on. From Matt’s advice I threw a jacket and hat and heavier gloves into a backpack and then used those for the “standing around” part of the ride to stay warm when not moving. I also had some USB hand warmers. I did not get cold, unlike my companions. (Sorry, guys!)

The ride back was just me, Matt, and Michael and the hills were killer. As in, they killed my will to live. I was going slower than I’ve ever gone on a ride. Somehow we took a path that seemed to have even more hills and at the end my legs were jelly. The whole trip for me was 5.38 miles there and 6.4 miles back. I’ve done rides that long or longer without issue, but they are at my own pace and avoiding large hills.

Oh, I forgot! The ride has this whole “coffee outside” thing. The idea is you ride to the location (takes about 30 minutes) hang out outside for about an hour drinking coffee, socializing, etc., then head back (another 30 minutes). So it’s like a 1 hour ride with a 1 hour break in the middle. I don’t drink coffee but did bring some hot chai tea in an insulated mug for this one. Sometimes there are snacks as well. Again, it’s all really chill and a nice little community of people who like to ride bikes.

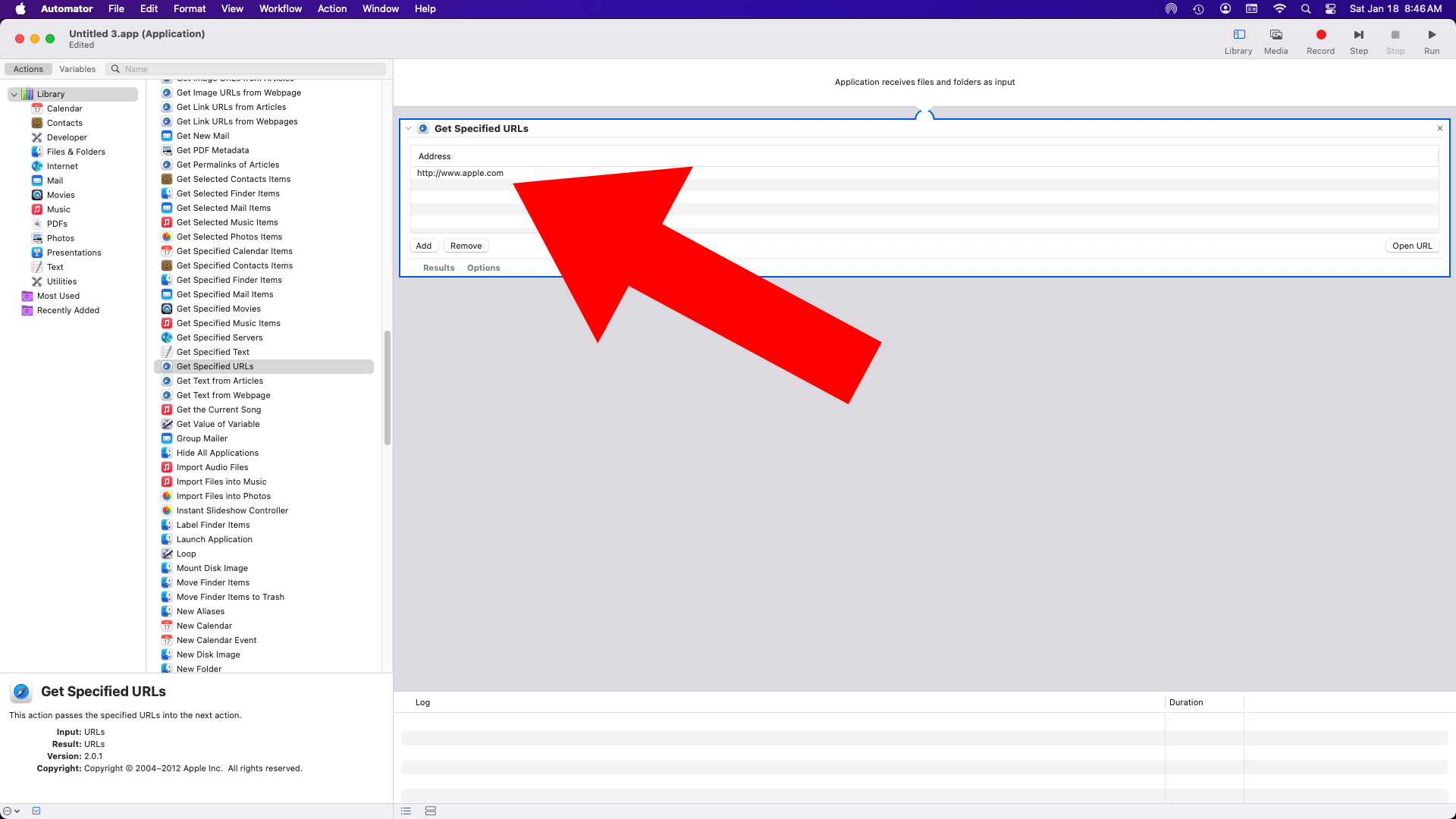

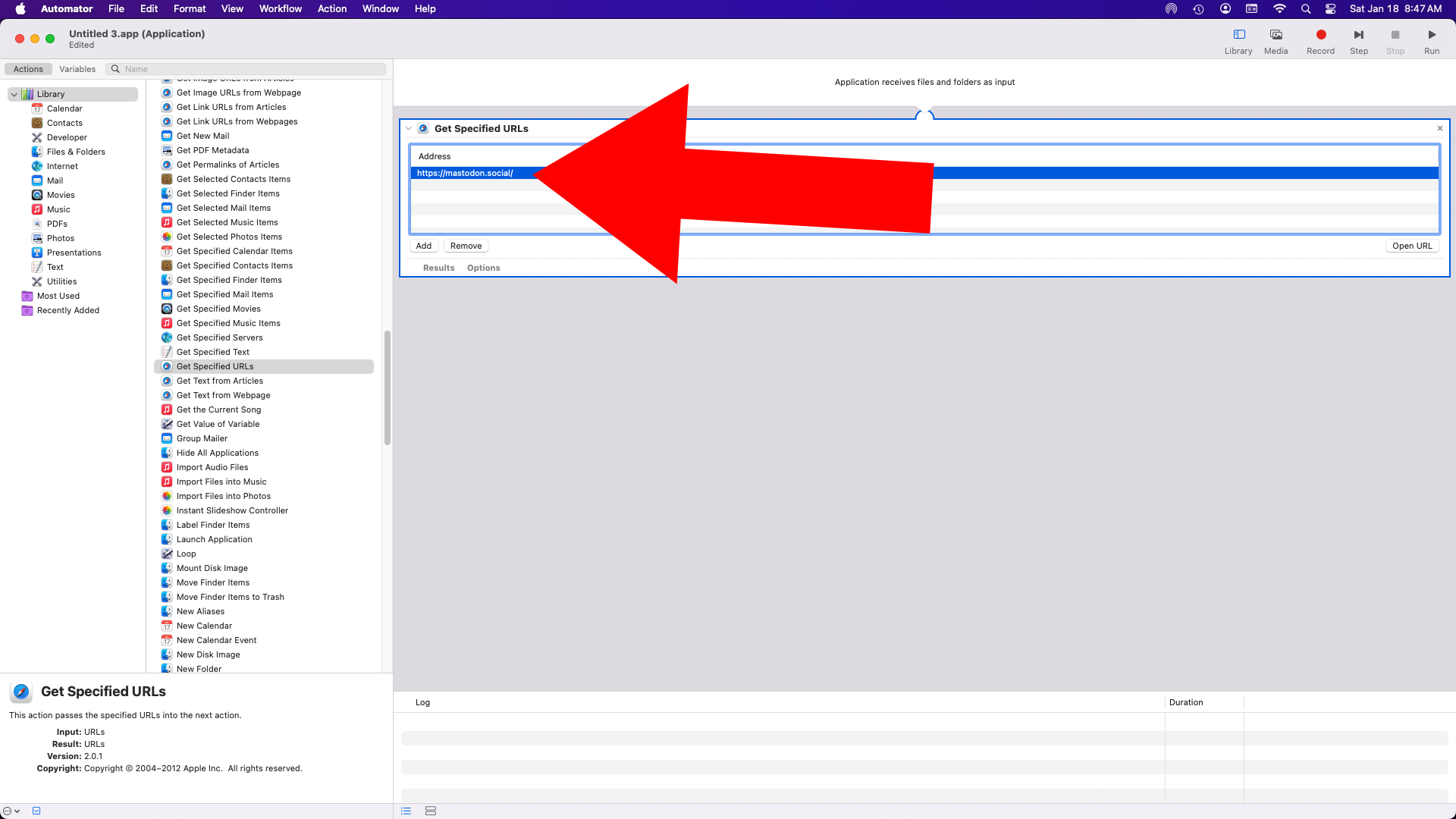

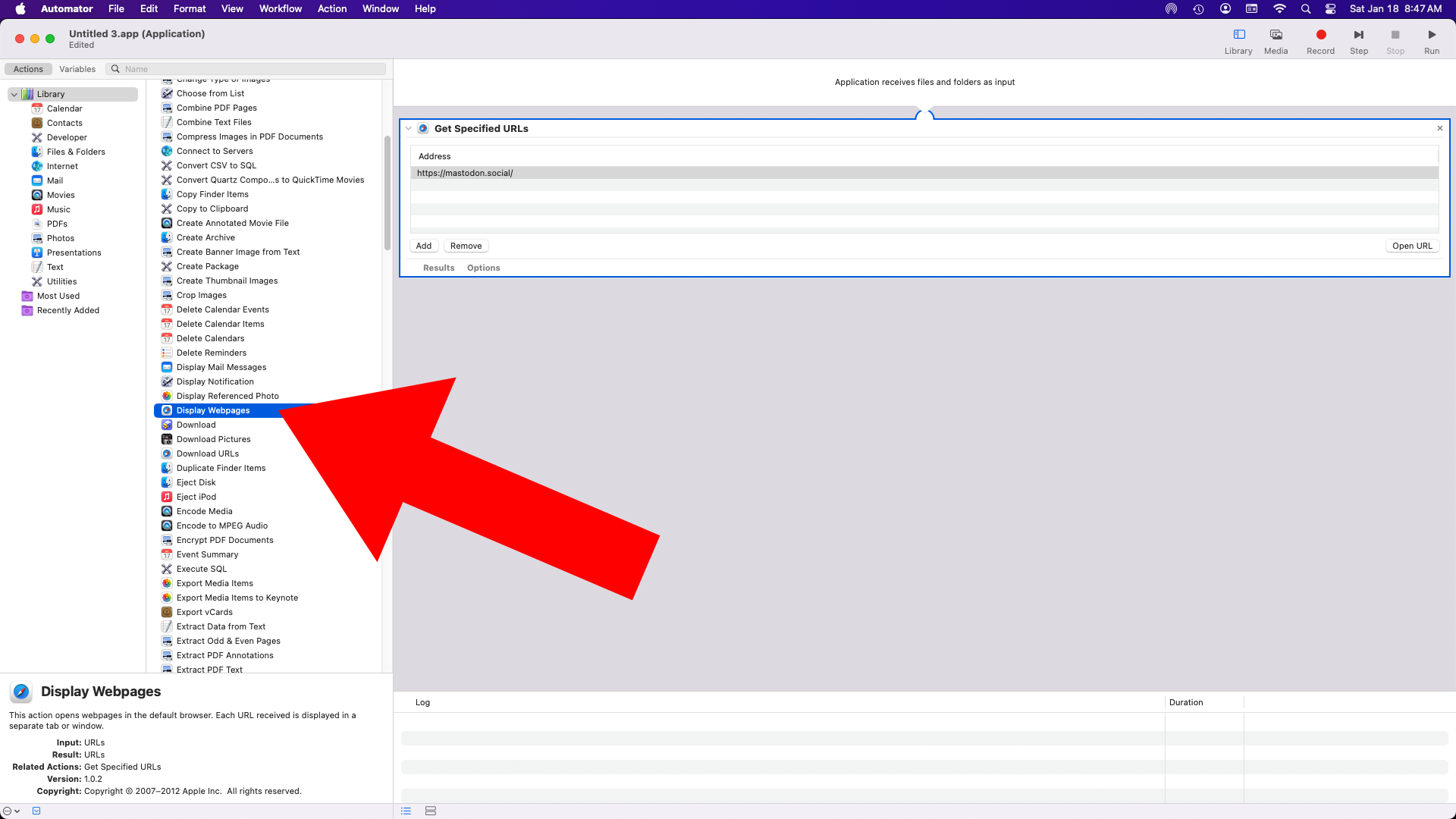

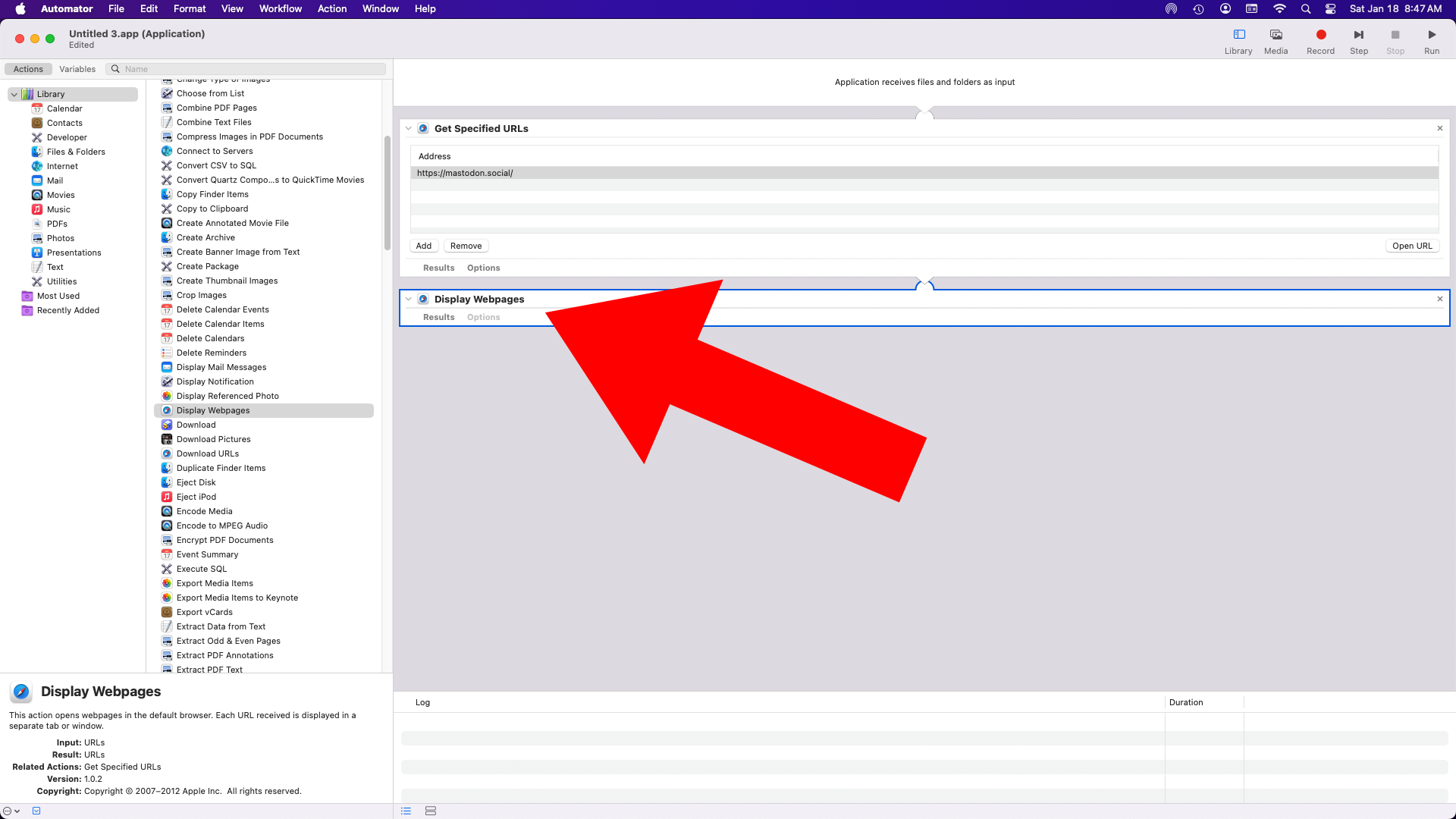

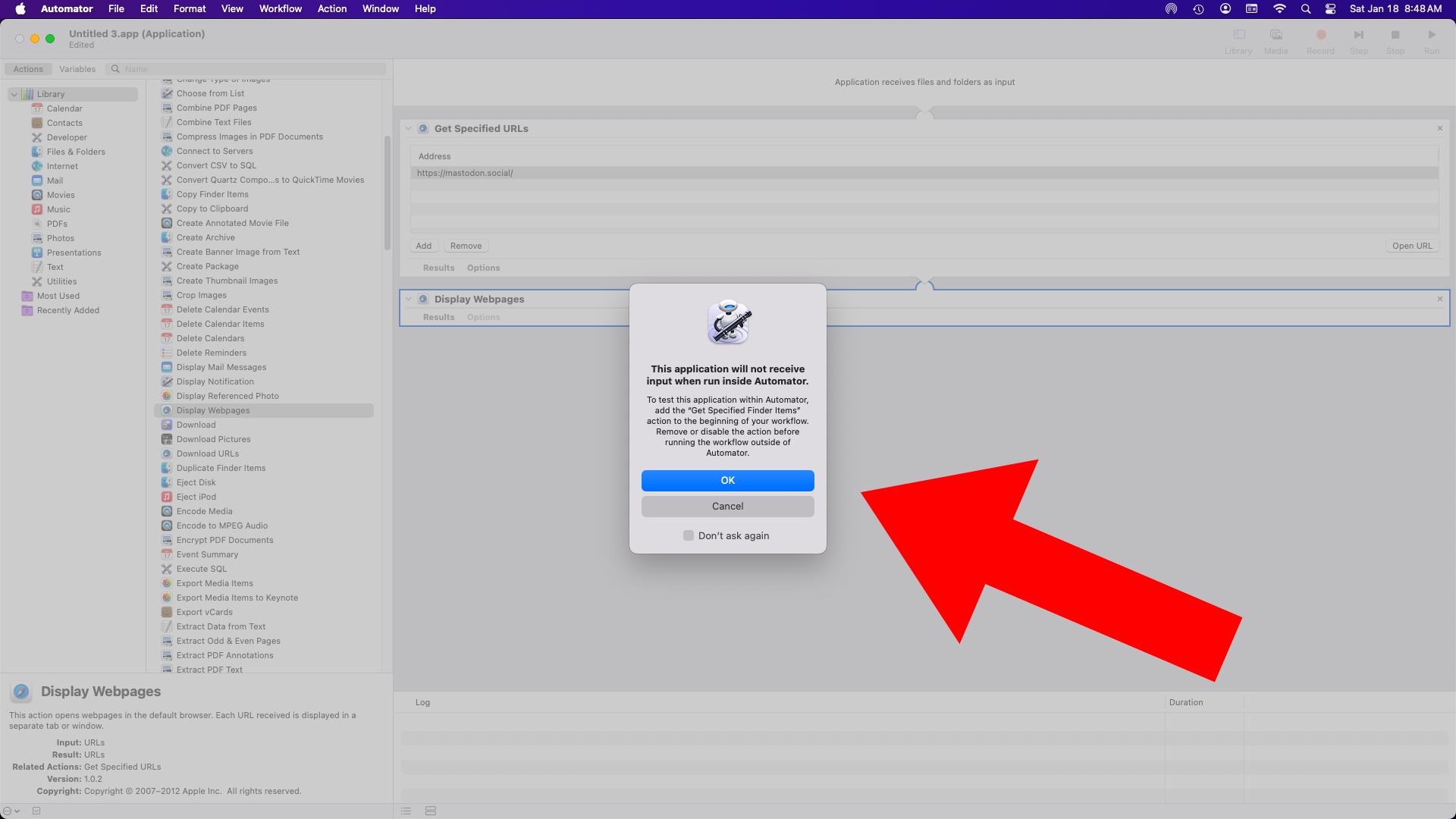

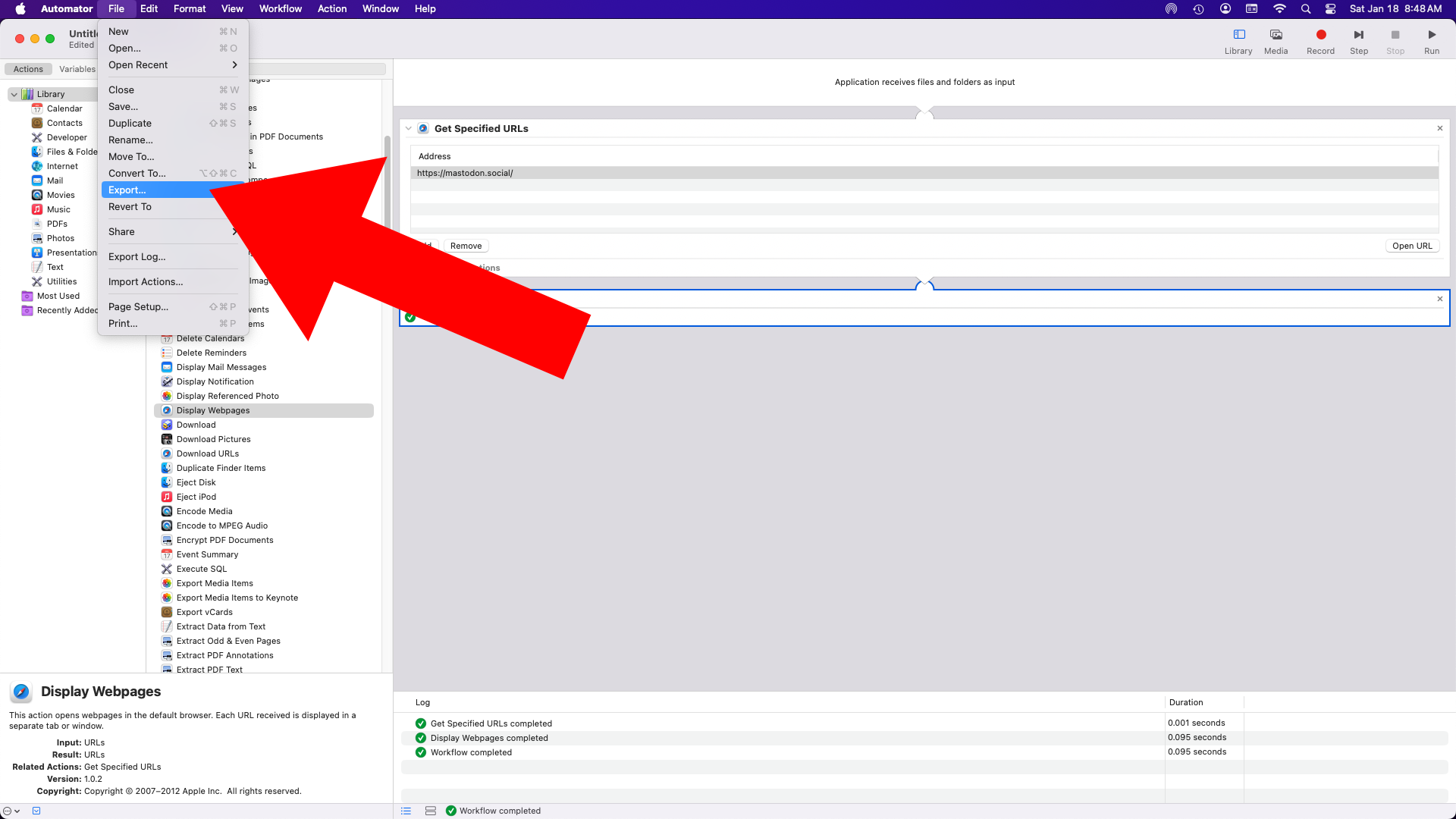

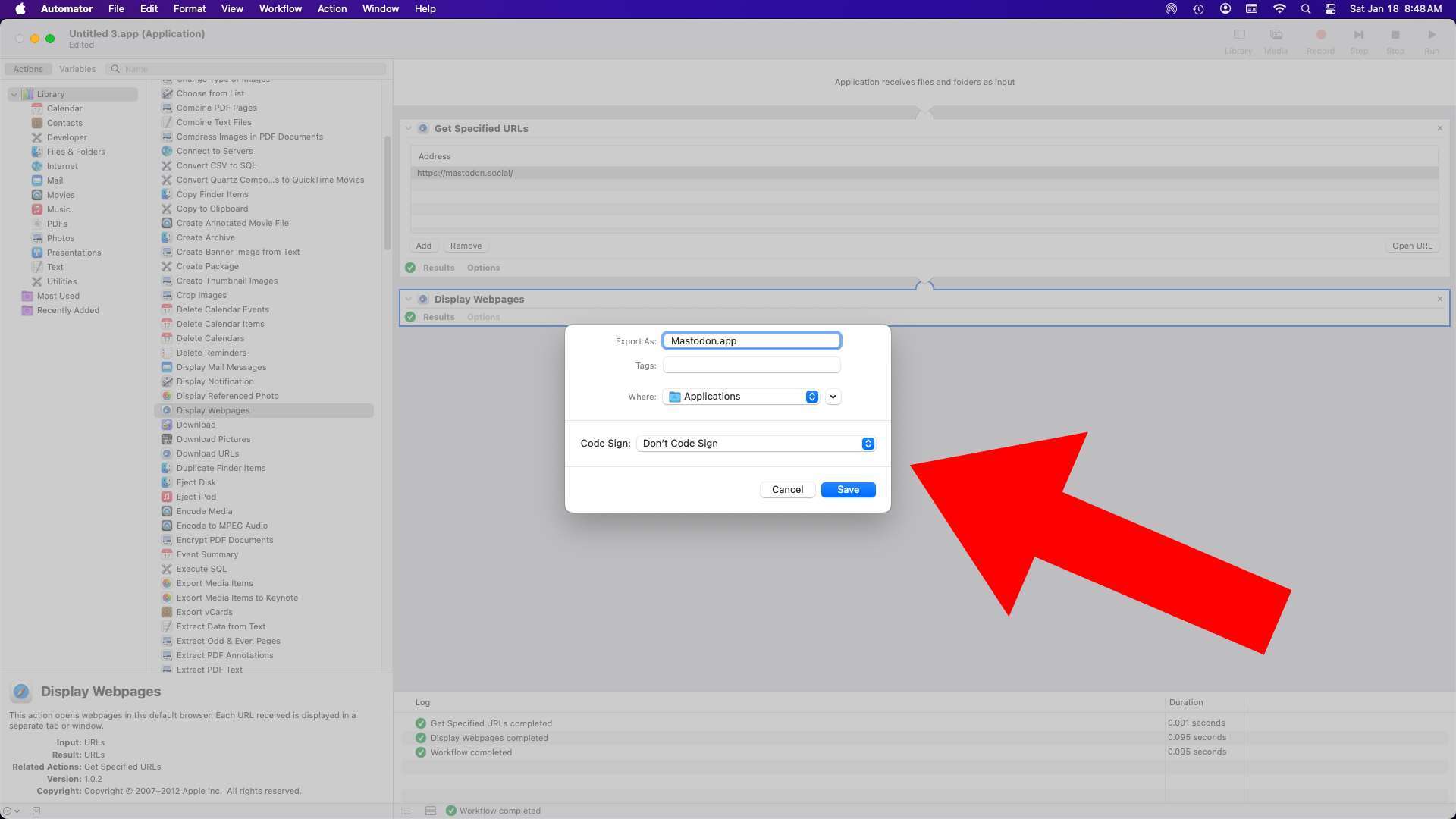

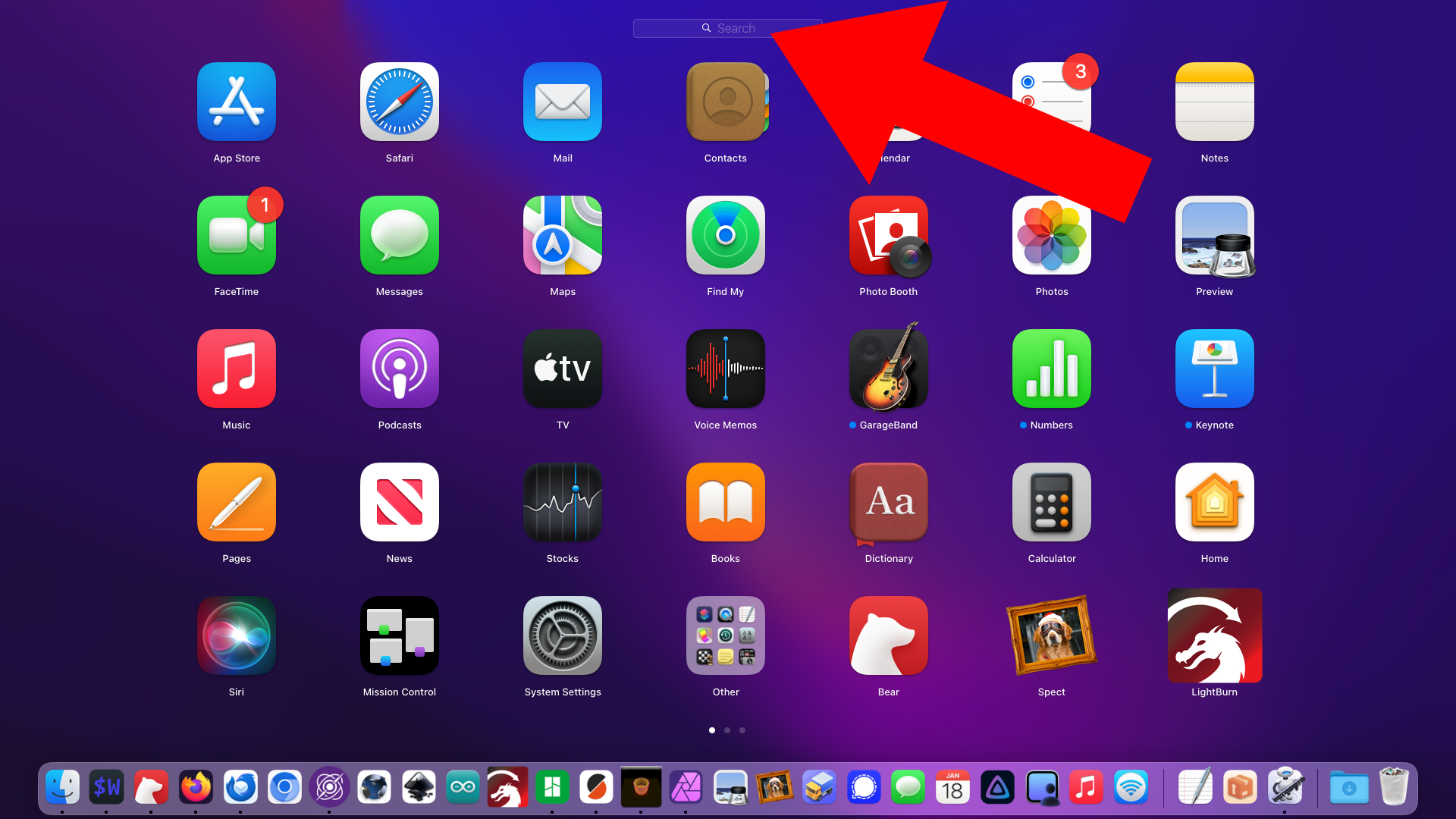

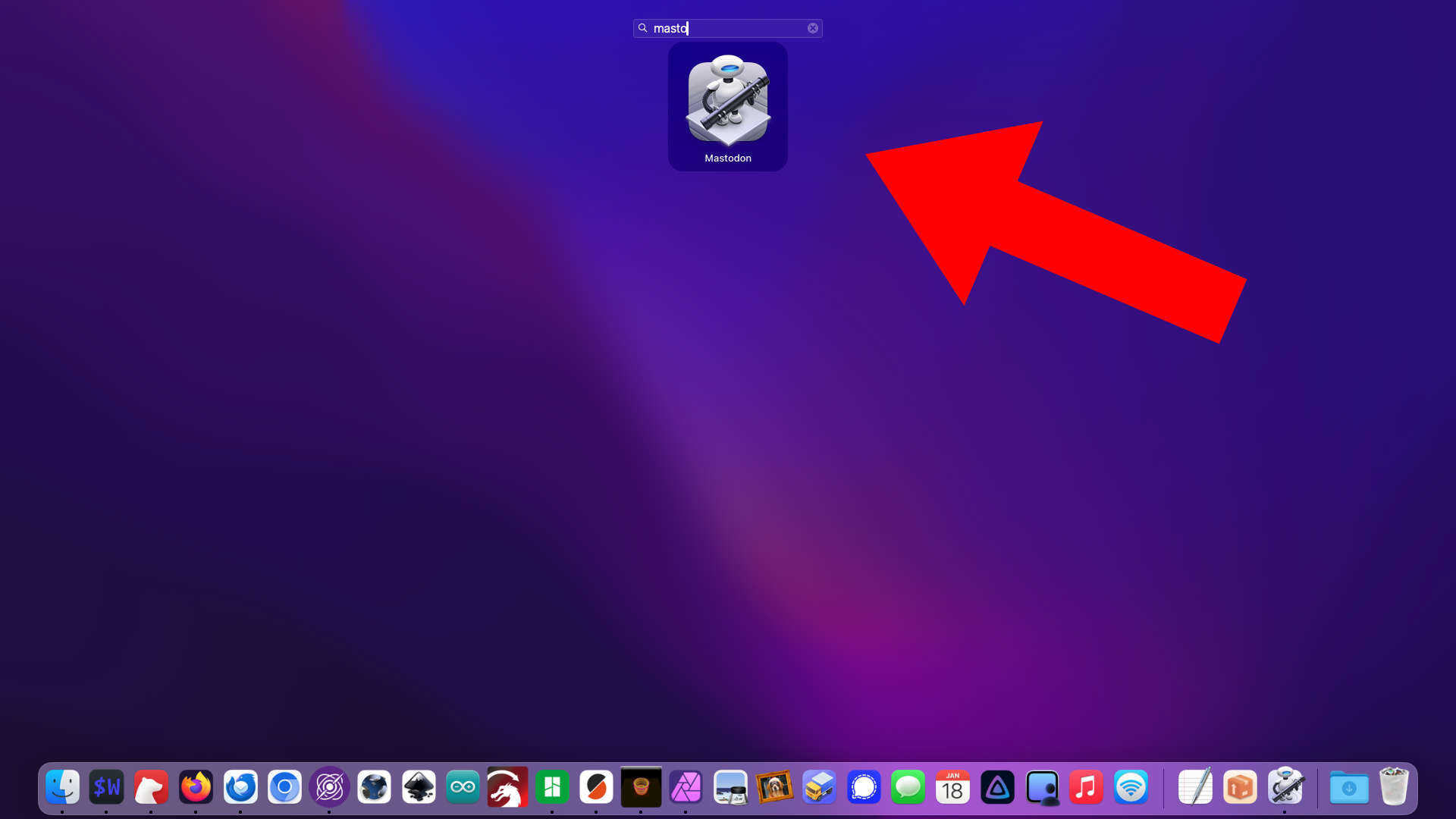

Right now if you want to find out about rides check out Scrappy Hour MKE on Instagram. They are in the process of adding a Bluesky account (which I’ve asked them to bridge to the Fediverse) and they’ll be starting a mailing list as well. (Email scrappyhourmke@gmail.com to get added!)

The next ride is Sunday, February 23rd, 2025 and typically the main group leaves from Cactus Club in Bay View at 9am, and then there might be groups leaving from Interval Coffee on the East Side/Riverwest and Rocket Baby in Wauwatosa, but the Bay View is the only “for sure” one and the rest are TBD closer to the date. (At least I think that’s right.)