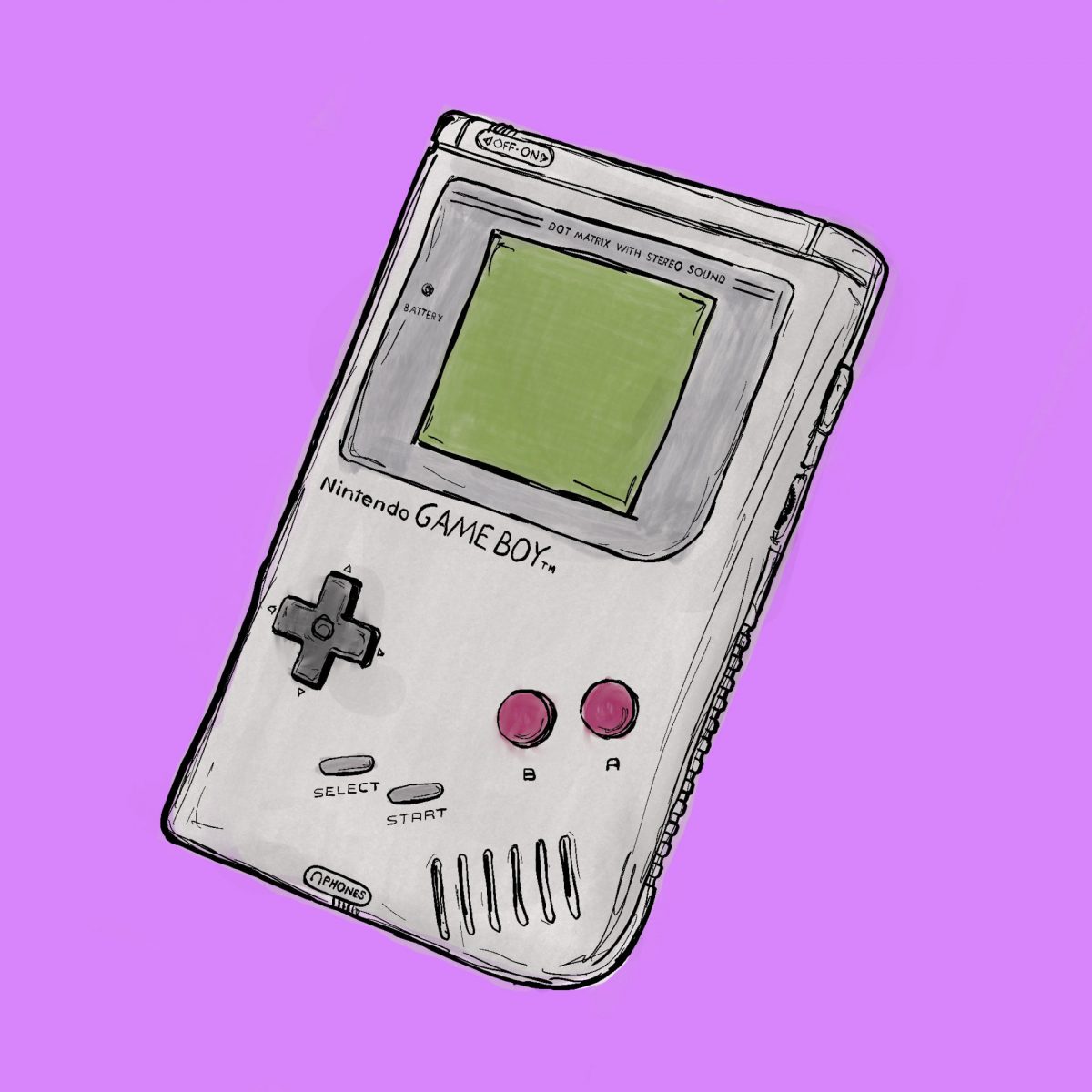

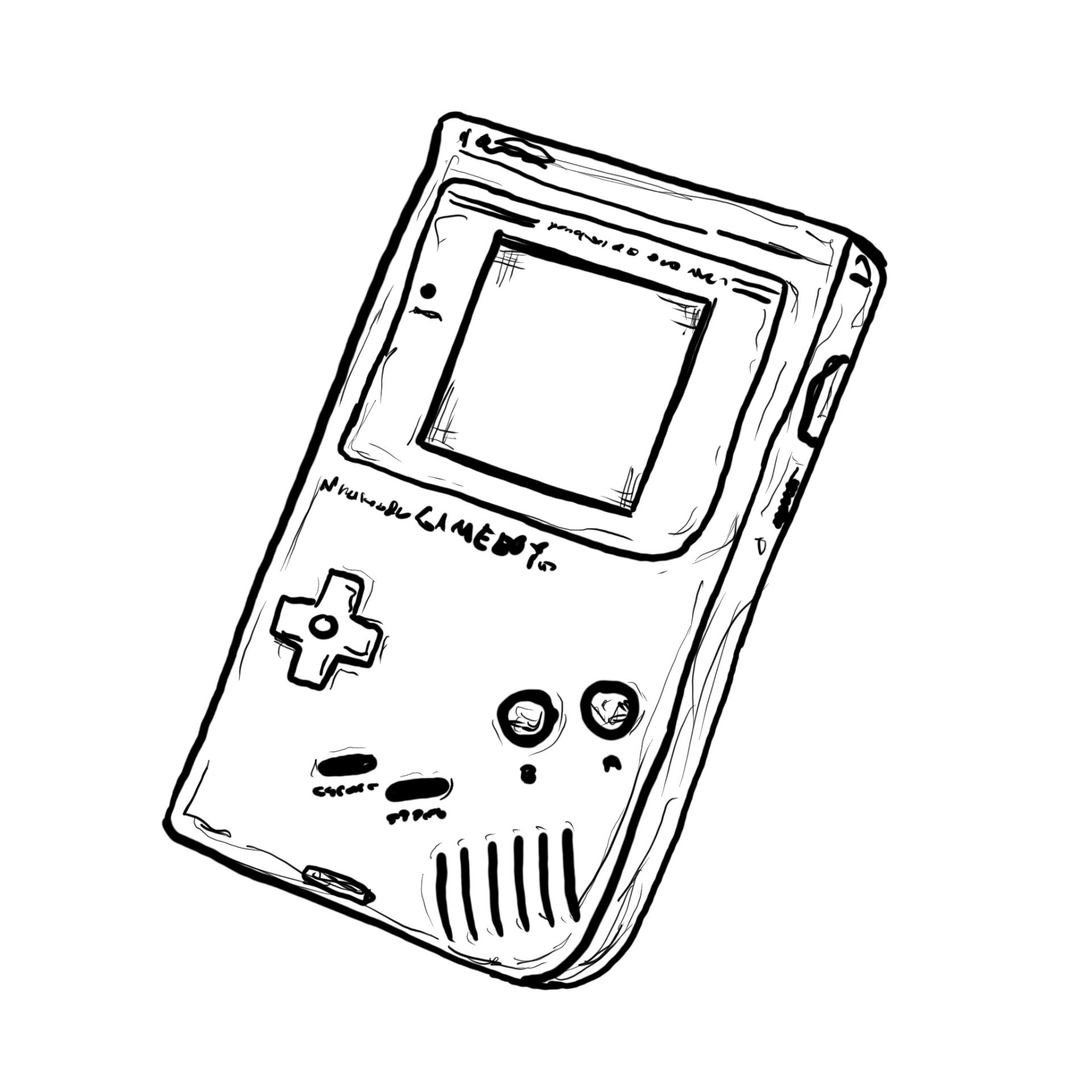

For me the peak of portable handheld gaming in the 1990s was the Nintendo Game Boy. I remember not having on, but using the one my girlfriend had. A year or so later we broke up but I got a new girlfriend and she also had a Game Boy. (Also, just a quick shout out to Adafruit for the Game Grrl.)

Anyway, past relationships aside, I pretty much just played Tetris on the Game Boy. So yeah, Tetris… which led me to the Anbernic RG35XX last year. I probably spent more time playing Game Boy games in 2023 than I did in all of the 1990s.

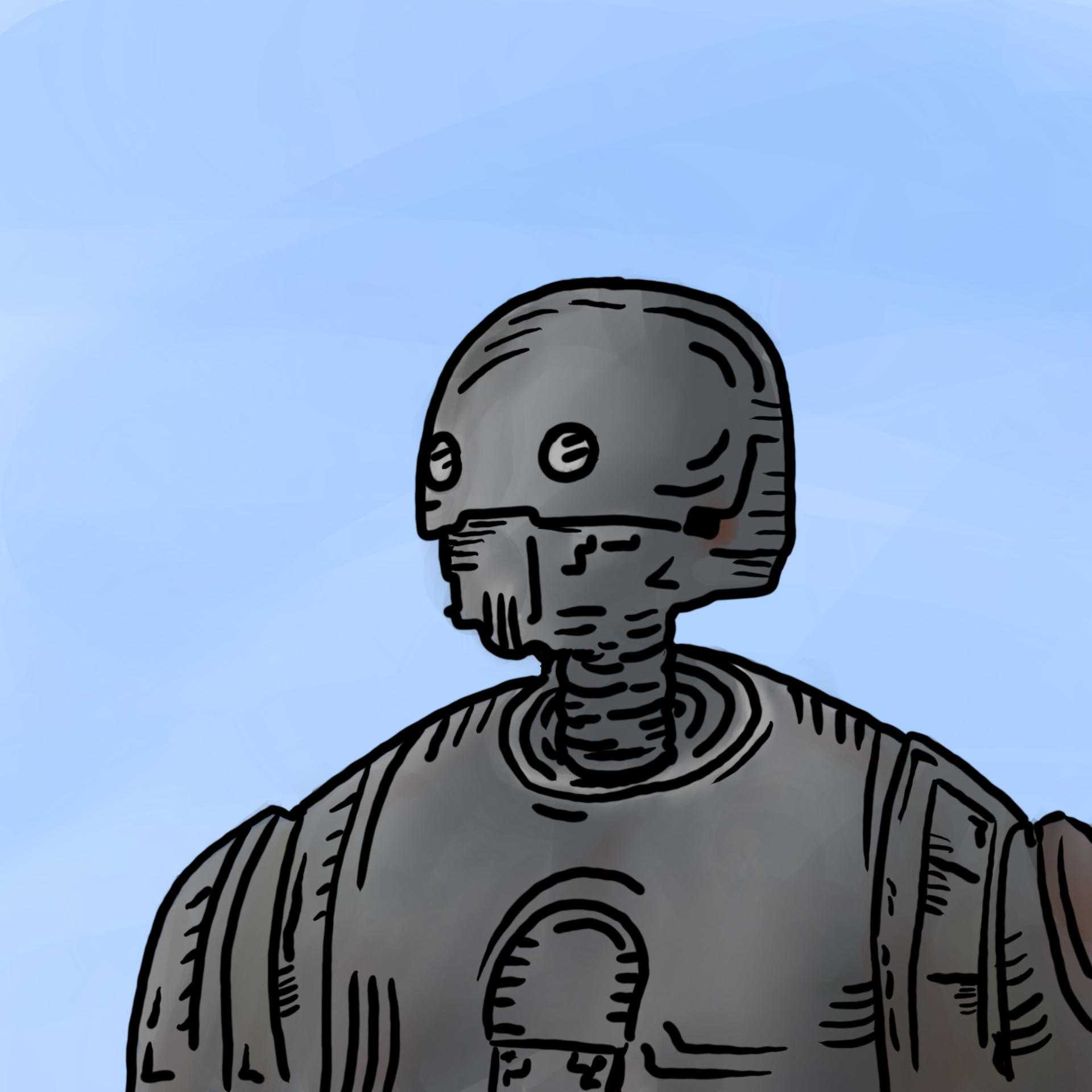

For these sketches I always start with the lines, typically working directly from a photo, doing some tracing and making decisions about each hand drawn line. Damn I am really enjoying the capabilities of the Apple Pencil! I still have a lot to learn and I spent about 20 minutes watching a video over the weekend and learned a few Procreate tricks I was unaware of…

I should probably spend a bit more time just screwing around in Procreate and doing some real learning but I also find the drawing so fun and enjoyable that I mostly try to do that when I have a small amount of free time.

Finally, here’s a more loose and sketch version. Once again this digital illustration was done with an Apple Pencil on an iPad using Procreate.

Oh, just a quick side note, I do have a Game Boy Advance for my Game Boy Camera but I sort of wish I had the Game Boy Color because the form factor seems much better for using the camera.

Note: This post contains an Affiliate Link. Read More.