We have this sink organizer thing that holds a sponge, a bottle of dish soap, a scrubber, etc. and there’s a little plastic plug that goes into a drainage hole in the bottom of it. Well, there was, but it wore out and broke, so I made a new one.

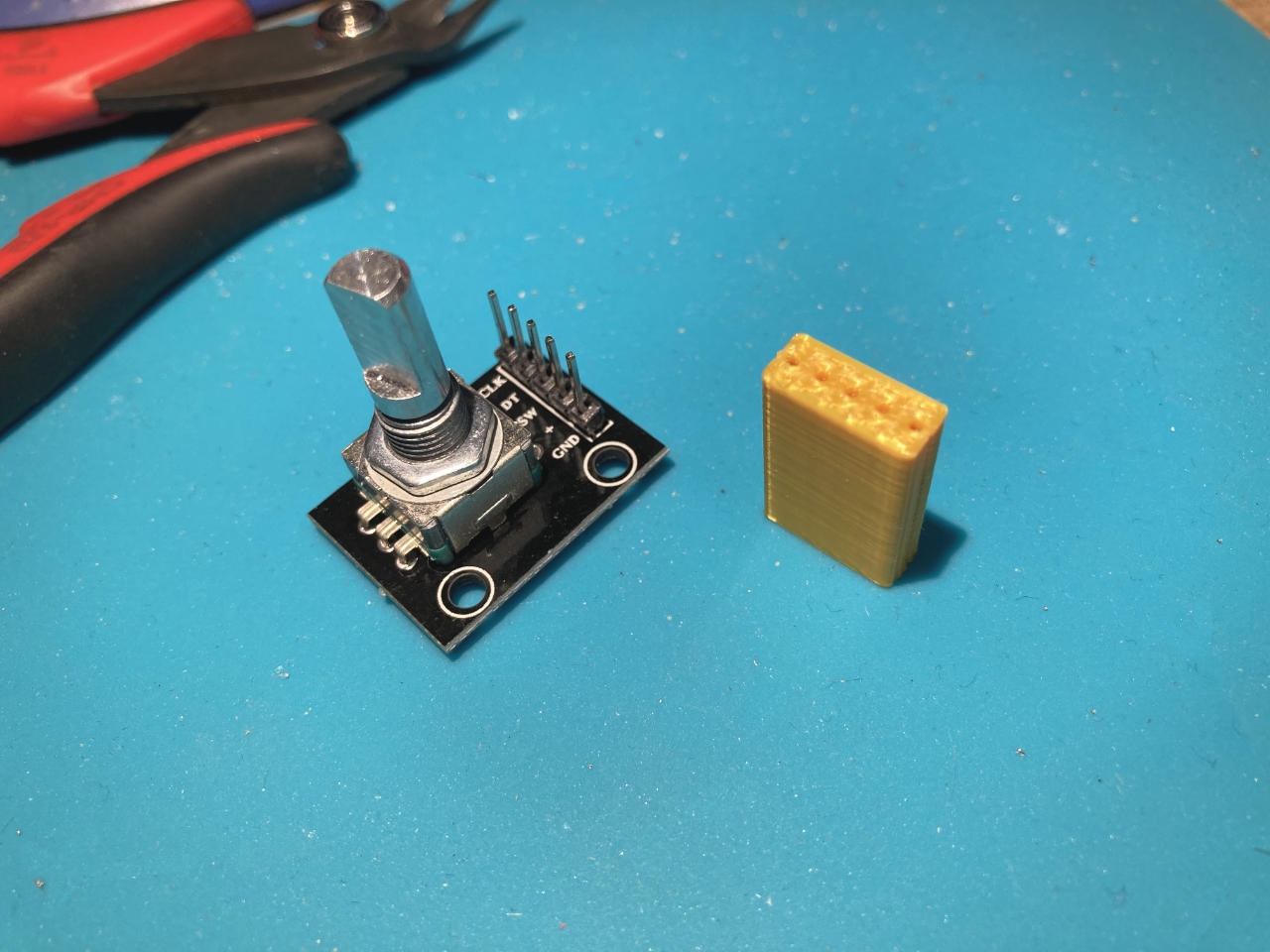

I modeled one in OpenSCAD based on the measurements of the broken one…

Then I used that to difference it from a block to create a mold I could 3D print using PLA plastic. (I did consider printing in TPU but I had to do some other silicone casting as well so I went this route.)

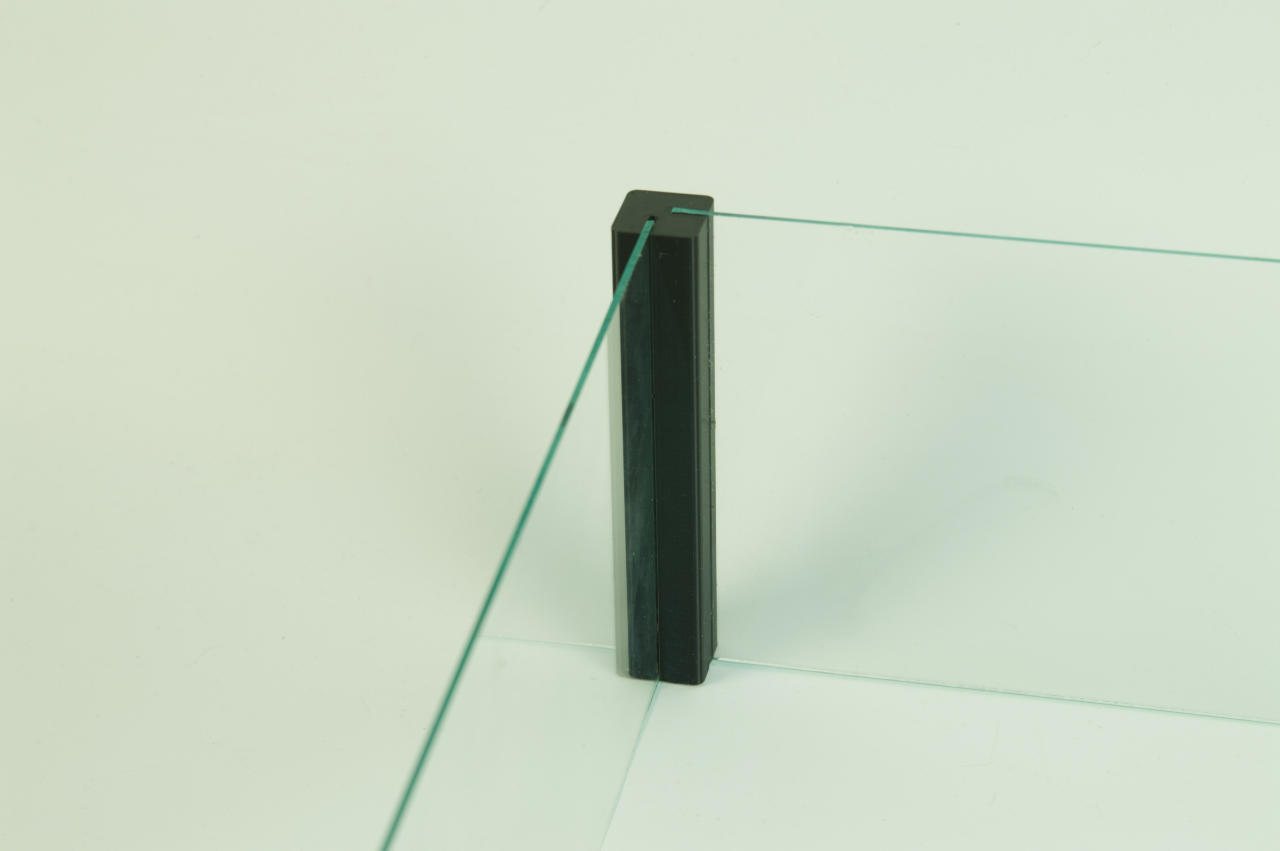

Here’s the new plug made from silicone. It’s pretty simple, nothing fancy, so I assumed it would work just fine.

Here it is stuck into the hole. It’s flexible so it squeezes in just fine…

Here’s a view from the top where you can see the plug in the hole. Again, a simple project. I’m hoping it holds up because another cast I did with this silicone came out a bit weird.

In this closeup image you can see the lines in the piece caused by the 3D printed mold. They don’t matter for this sort of thing though. (I probably didn’t print the mold at a high resolution.)