I used to make plate for relief printing by laser etching wood. When I got the Provisional Press I basically set it up optimized for working with 3mm plates, since I used 3mm Baltic Birch wood to make plates. Well, a decade ago I was playing around with 3D printed plates, so I figured it was time to revisit that idea.

First, a few advantages to 3D printing versus laser etching. Since the plates are only 3mm tall they print fairly quickly (at least compared to much taller 3D printed objects) and using the laser cutter involves being there watching it and running the (noisy) water pump, air assist, and exhaust fan. While the laser cutter is (usually) faster, you can just hit “Print” on the 3D printer and walk away. Come back later and you’ve got a plate!

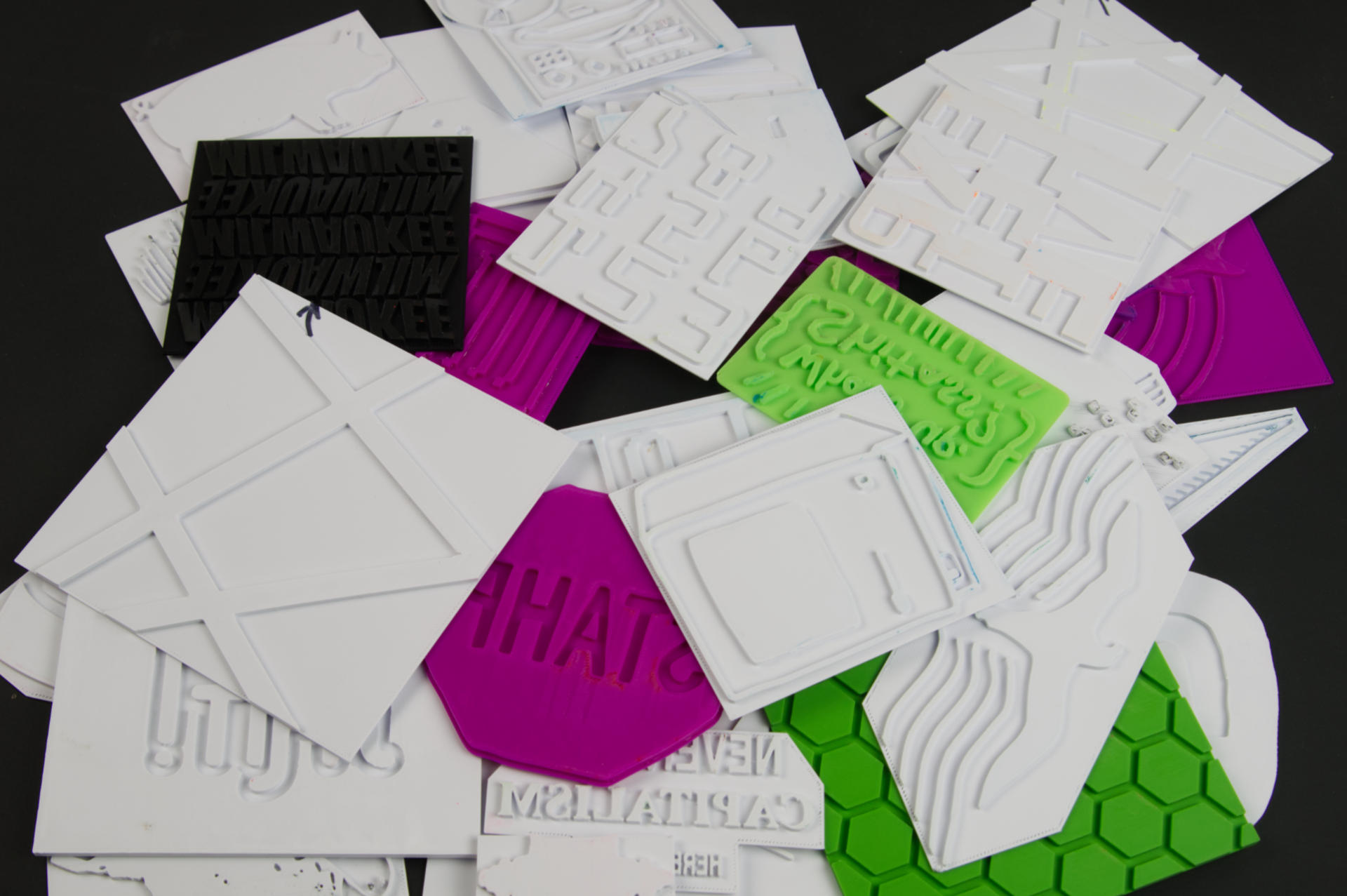

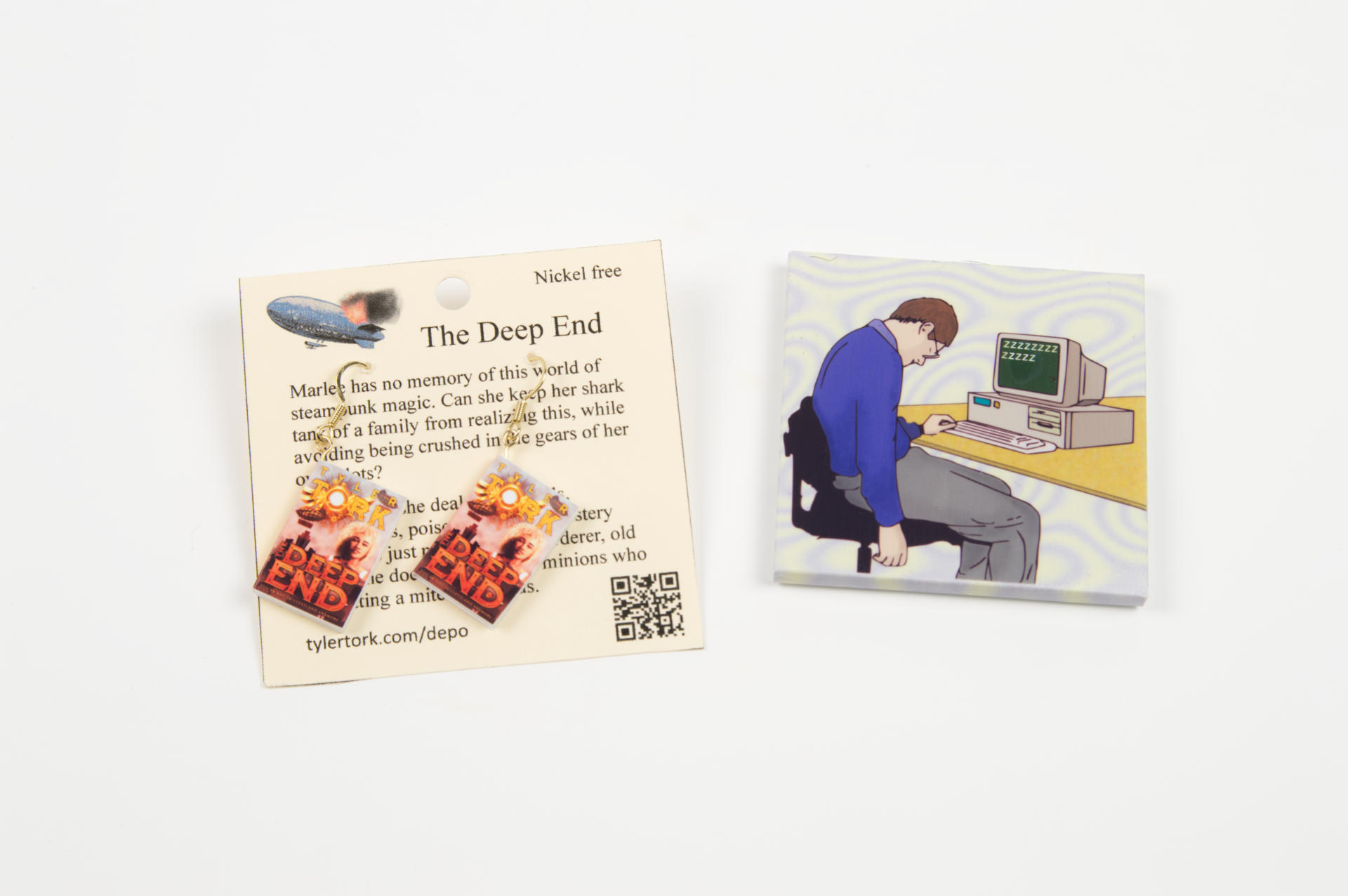

Every plate I used for my January 2024 prints (over 40 at this point) was 3D printed.

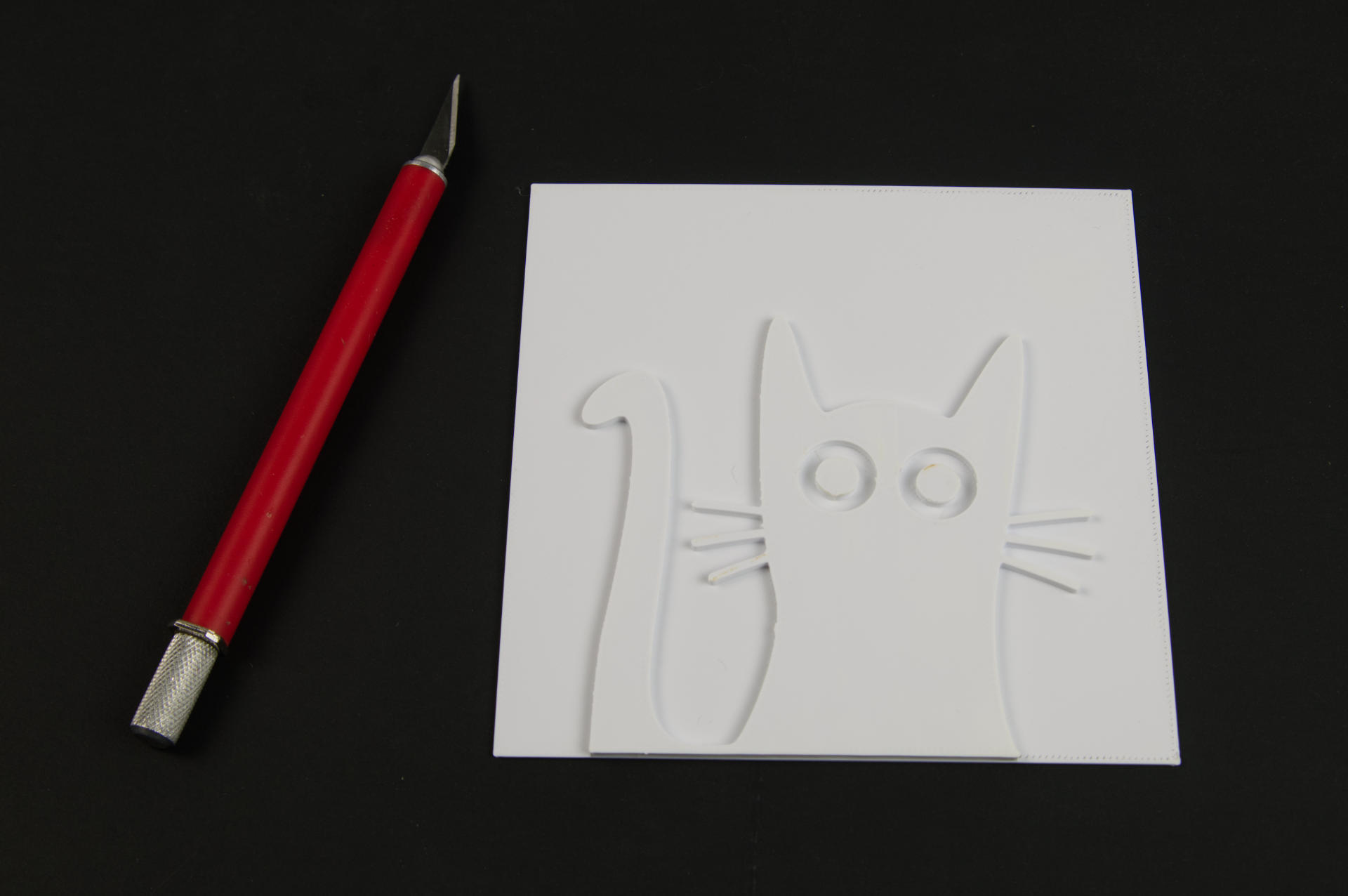

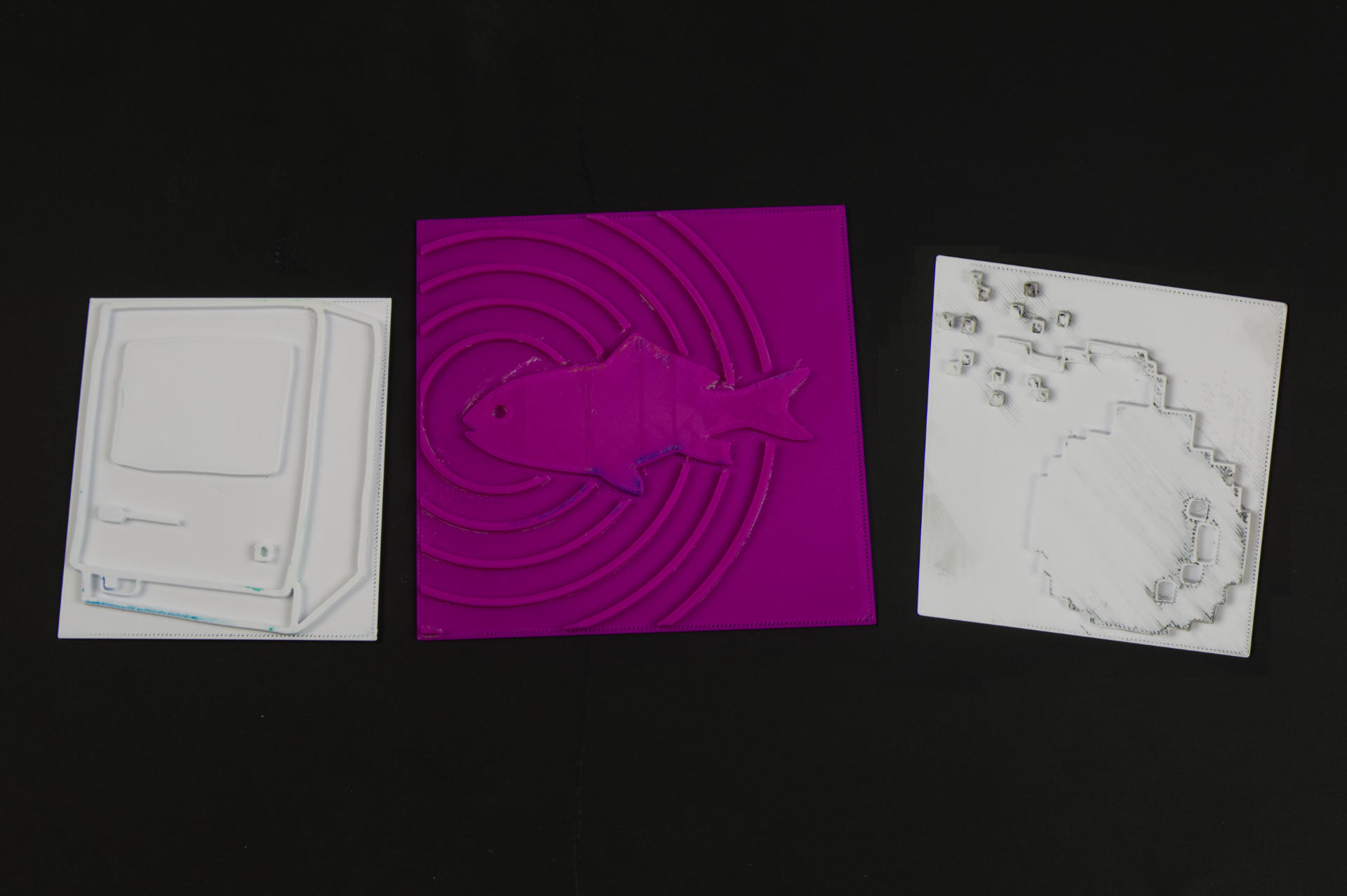

For wood plates I would typically sand them and then coat with shellac, which is not completely necessary but can help with the top surface. With 3D printed plastic plates I turn on the ironing feature in the slicer software to give the topmost layer of the print a nice smooth surface. I do tend to sand the plastic plates as well, typically less than a minute with 400 to 800 grit sandpaper.

Ironing doesn’t always work perfect, so the sanding helps knock down any little imperfections on the top surface. Again, it’s not a lot of sanding, just enough so the surface looks smooth with no (or very few) imperfections. Of course the imperfections might be what you are going for! The one thing you’ll see in linocut prints is chatter. (Chatter is the unwanted printing caused by areas that were not cut away enough in a linocut.)

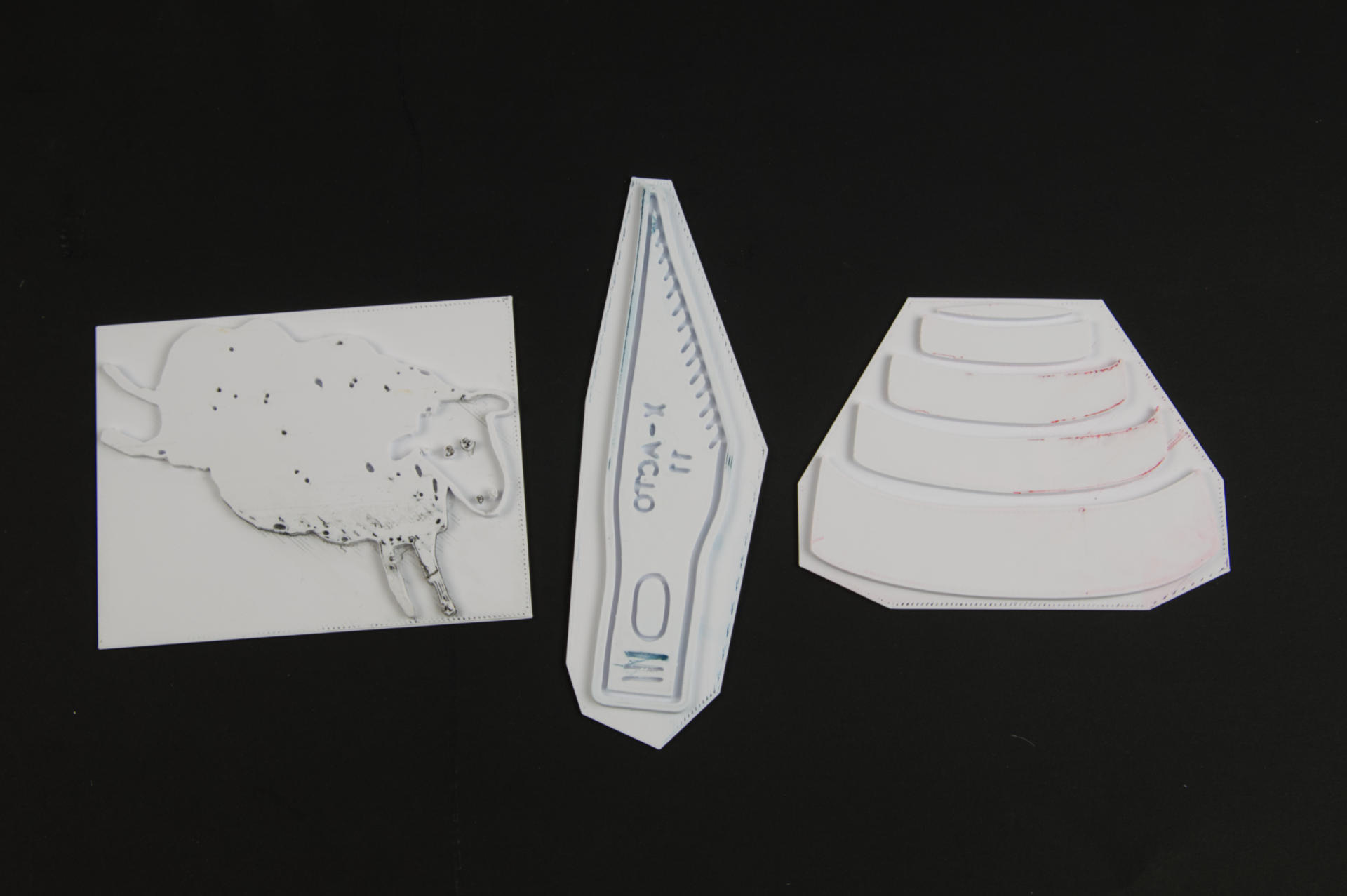

I think chatter adds character and sometimes it adds a lot to a print. Since 3D printing is an additive process there is no natural chatter like in linocut, but sometimes you do get a sort of reverse chatter where a print doesn’t have a perfect surface and you get interesting artifacts when using a 3D printed plate. I am 100% fine with that and I embrace it.

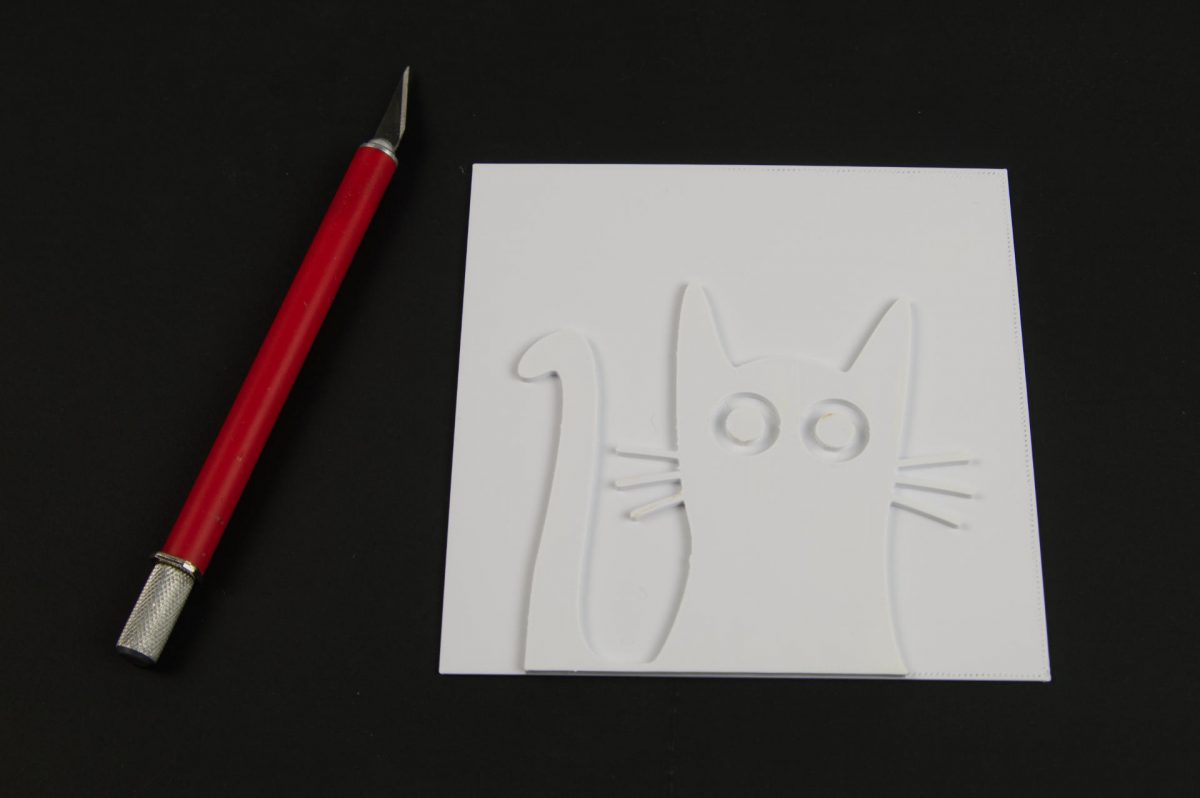

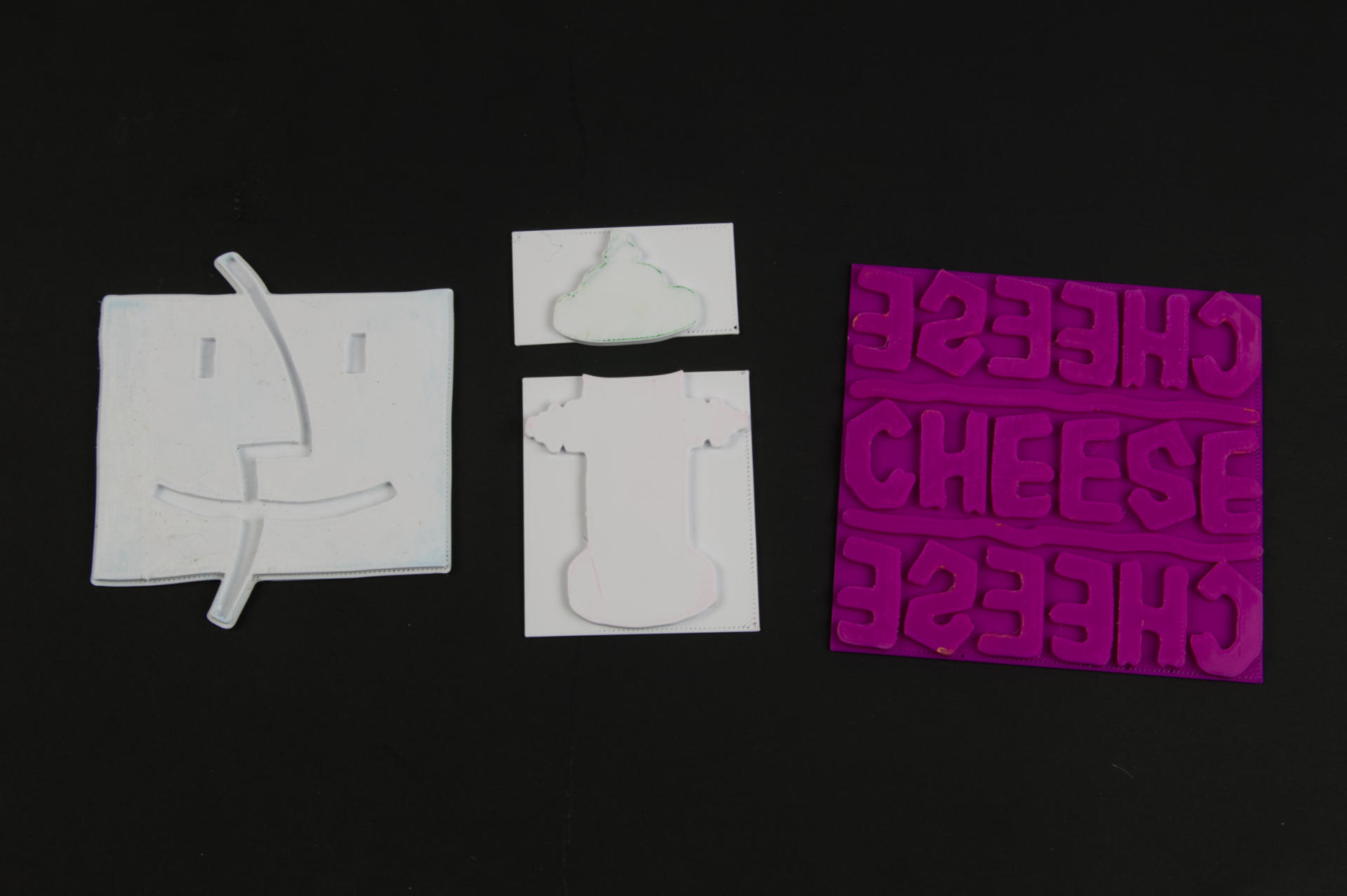

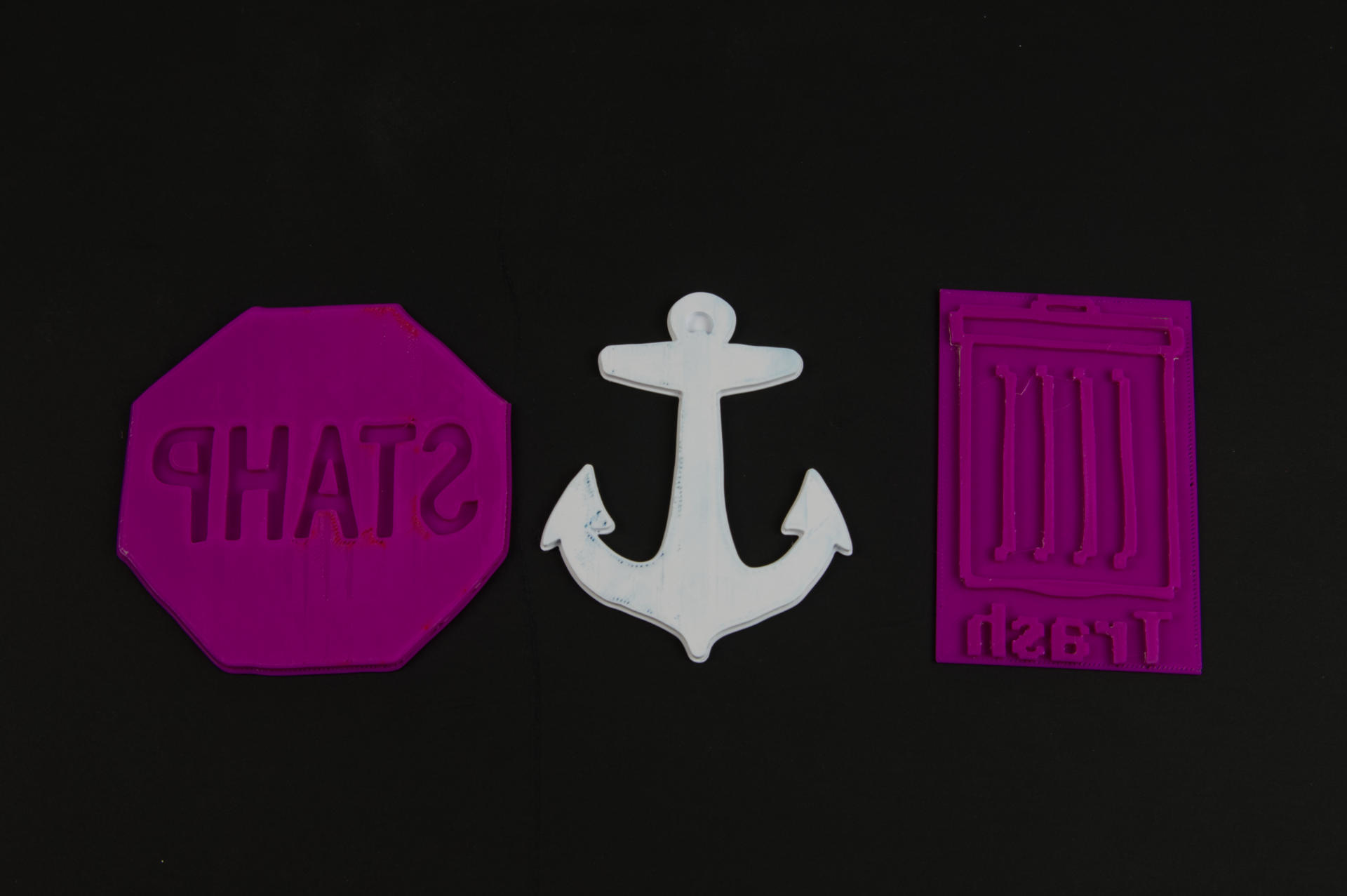

Now, 3D printing doesn’t always work. For small fine detail it can be tricky, especially depending on your 3D printer and how well tuned it is. Simple designs tend to work best, at least for the smaller plates I’ve been making. The laser cutter still wins for “thrown any image file at it set to etch” and it’ll probably work. For 3D printed plates you’ll also have issues with really fine lines. (Granted, fine lines can also be an issue with the laser cutter but they seem easier to fix.)

One more advantage of 3D printed plates is that I feel like the plastic will last forever (oh, maybe that’s a bad thing?) while the wood plates do seem to wear after repeated use and washing. Remember, the wood I use is thin Baltic Birch, not hardwood like letterpress.

As for the filament, I use plain old PLA. Often it’s MatterHackers MH filament, but I’ve used PolyMaker PolyTerra filament as well. Really any regular PLA should work just fine. Color doesn’t matter, but I ended up using white for a lot of plates because I had white filament loaded, and it is pretty easy to see the ink on the plate, unless it’s white ink of course.

I should note, I am very much about making things easy because that means I am more likely to do it. If making plates is a pain then I won’t want to do it. Laser etching the plates was a little bit of a pain, but not too bad. The thing I like about 3D printing the plates is that I can create the file and then send it to the printer and in about an hour I’ve got a plate. I don’t have to babysit the 3D printer the way I do the laser cutter, and I can easily make the back part of each plate exactly 1mm tall, unlike with the laser etched plates.

So right now I 3D print my plates, and have well over a dozen prints made this way, and they work quite well, which means I will keep doing it. Stay Printing!

One more thing… since we are using digital fabrication to create the plate not only can we make a replacement plate, but we can change the scale quite easily. This is an advantage over analog plate making methods where you create a plate by hand.

There’s another post that is more of a “How-To” for making 3D Printed Printing Plates using Inkscape and OpenSCAD, so check that one out as well.

Update: Someone asked if the plates are easy to clean. I use water-based inks so I just scrub in a sink with soap and hot water. Sometimes voids in the plate will get some ink in them that doesn’t come right out, but scrubbing with a toothbrush can help. Absolute worse-case since this is digital fabrication you can print a new plate.