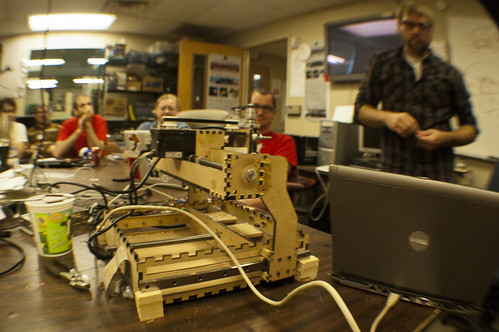

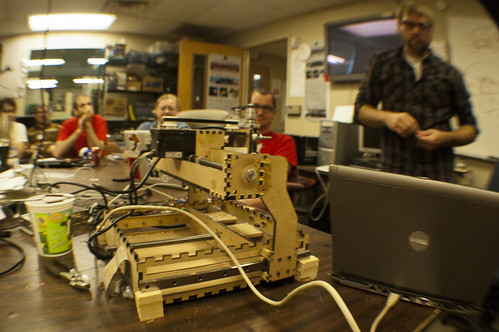

You may have heard me talk about the Shapeoko, a DIY CNC Mill you can (well, should be able to) build for around $300. Edward Ford, the guy behind the project, just wrapped up a Kickstarter campaign to fund the project. And just to be clear, he’s been working on this project for many years, it’s not like he just had an idea a few months back and launched a campaign. (2004 is when he first attempted to build a CNC Mill.)

Edward was kind enough to make the drive up to the Milwaukee Makerspace and talk about Shapeoko with us. It was great to hear about the project, and I think he may have even gotten a few new ideas while he was here. :)

The goal of Shapeoko isn’t to build a business around selling these things, but to create a project that is fully open source, with easy to acquire materials. Typically when you find web sites describing a DIY CNC machine, they involved getting parts from ebay, or from scrap, or other unreliable sources. Edward wants you to be able to get all the parts you need easily, and not have to scrounge around and have a friend who happens to own a mill to make you parts.

Edward’s demo was great, because he wasn’t afraid to talk about all his failures. He admits he’s not an engineer, and he’s learned a lot over the past 7 years about designing and building things. A lot of his description of the project included “So I tried X, and that didn’t really work, then I tried Y…” type things. Experimentation, a bit of guessing, and a lot of testing.

We also learned a bit about running a Kickstarter campaign, and some of the gotchas involved with that. Like refunds, and how you can end up losing money if you issue one, and what happens when there are insufficient funds. Great tips for anyone interested in Kickstarter.

So now that the Kickstarter campaign is done, and instead of the $1,500 he was hoping for, he’s got about 7 times that much, he’s been ordering parts, and is working on a new design, correcting any of the problems that previous designs have had.

For more on the project, check out the web site at shapeoko.com, as well as the blog, Twitter, and the forum.