After I got the Bambu Lab P1S I stress tested it a bit with the 3D Printed Pegboard but before that project I actually printed this Gridbox which uses the Gridfinity organizational system.

The way Gridfinity works is that there is a grid (duh) and you print bins or other “things” that fit into the grid. The bins can be 1×1 or 2×1 or 4×4 or whatever fits into the grid. I actually used Gridfinity Rebuilt in OpenSCAD to generate these little bins because I prefer OpenSCAD to Fusion 360.

I scaled the height of the bins to the internal height of the Gridbox. I can tip the box over and all the hardware stays where it should. Almost. The washers are small and thin enough they occasionally end up in the top part of the bin where the labels are. I could probably solve this by gluing a piece of foam inside the top lid so it closes and provides just an extra bit of cushion. I may try that… If I did this again I would perhaps alter the bins just a bit to have flatter tops since I won’t be stacking these bins.

This really is a great way to store all of my 3mm hardware. As I’ve mentioned in other recent posts, I’m really trying to organize my shop and maximize efficiency. Before this I kept all the hardware in individual bags and then in a larger bag, which meant pulling out all the bags, grabbing the one I wanted, opening that bag, getting the hardware, etc. Again, let’s make this easy. I can also see how much hardware I have in each size easily, as compared to being stuffed into bags.

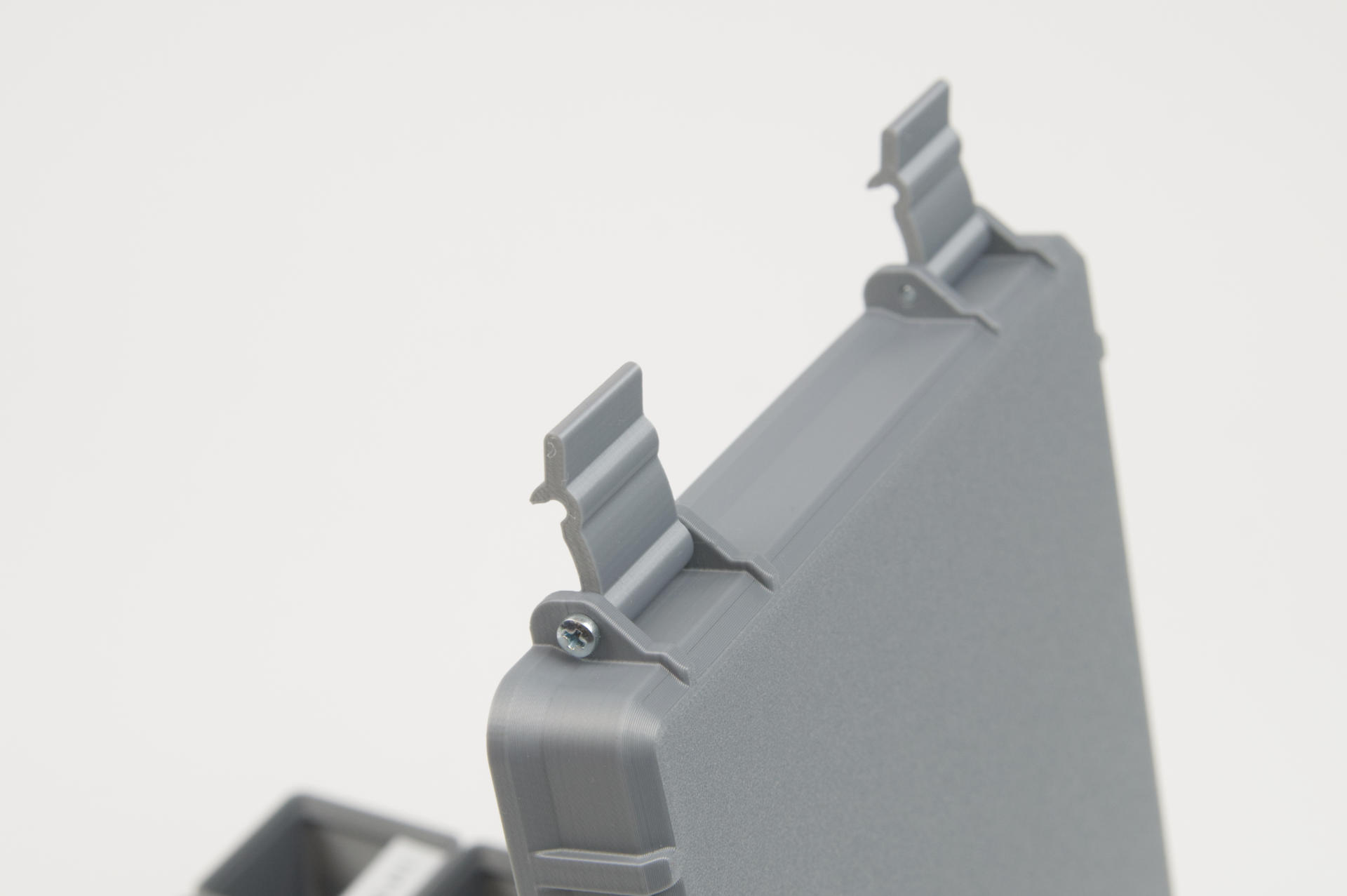

This Gridbox is a really nice design. I used the 4×4 version and will probably make another for my 2.5mm and 2mm hardware. There’s also a version that allows for a clear acrylic laser cut piece to fit into the top lid so you can see what’s inside. I don’t need that for my hardware, but it is a useful feature.

The model is based on the Rugged Box (Parametric) by Whity, which sadly is only parametric if you use Fusion 360. Sigh… I did find this Parametrizable Rugged Box (OpenSCAD) by Dochni but I don’t love it. I’ve started to try improving the code to do what I want but then I just started to write my own which I haven’t finished yet. (Note: See Rugged Parametric Box in OpenSCAD for a great new model!)

Besides a few things that give it away as 3D printed, this is another print that just does not look printed. The quality of the print is so good, and the design is top notch, so yeah… we’ve come a long way since 2011.

Anyway, the 3mm hardware is now sorted! That said, I have been using my Parts Tray with Sliding Lid for over a year now and I’ve been quite pleased with it. I may make a few changes to it though, as there are a few specific pieces of hardware I like to have at the ready.