If you happened to see a post titled 8 Crazy Keyboards That Will Trick Out Your Typing over on the Make Blog, you may have seen the big keyboard I worked on last year.

It was for a graphic design station we built for “Word Headquarters” at the Betty Brinn Children’s Museum. (I did this project as a contractor, before I worked at the Exhibits Shop.) Here’s a bunch of images that show the building of the keyboard.

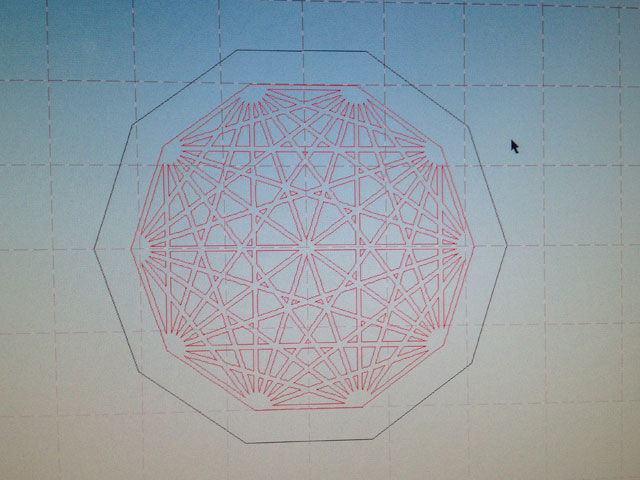

This is the concept Mike came up with, which was to use lots of different sized pieces of wood, CNC’d to look like letterpress type (though obviously not reversed, as they would be unreadable.) This was definitely a fun design, but things always change along the development path…

While Mike was working on a design, I mocked up a drawing showing the spacing I thought would work using arcade buttons and how close together we could get them. This helped determine the overall size of the keyboard. Things could obviously get more spaced out, but this was the tightest we could go.

I’ve built plenty of keyboards over the years using Teensy development boards so there wasn’t too much new happening on that front. Still, it’s always good to breadboard things up for testing.

We ended up going with a simpler and cleaner key layout than the original concept. As you’ll see later, we added variations elsewhere in the piece.

Did I mention the keyboard would have 46 keys? Well, 46 is the number of digital inputs you can get on a Teensy++ 2.0 board. That’s every single input. (And yes, there was an issue using pin 6 which eventually got solved.)

Here’s a big piece of HDPE that’s been milled out for all of the buttons. Yes, that’s a lot of buttons! (There are 47 buttons because we used two for the spacebar.)

Here’s the back of the big piece of HDPE. That’s a lot of wires! We used slip-on connectors rather than soldering wires to the buttons (for ease of maintenance) and the other ends of the wires all go to screw terminals.

All wires run to screw terminals on an Adafruit Perma-Proto board. It’s not the cleanest thing, but the deadline was tight on this, and the impending launch date meant we had to get it all done and working, even if it wasn’t the prettiest under the hood. (And yes, this is mid-wiring… not everything is connected yet!)

More wiring, more wiring, labels for everything… And testing as we go.

Here’s the piece of Alupanel attached to the top of the HDPE. It also serves to hold the wood keys in place. Each key has a lip at the bottom to hold it captive and is held up by the spring in the arcade button. (At some point I did weight tests to determine a safe weight for each key so that it wouldn’t press down on the button too much.)

Since we went with a uniform size for the keys, we added some variety in the choice of woods used. You may notice there is no return key. We eventually replaced the exclamation point with a return key. (We honestly didn’t think we’d need one due to the way the application allowed the use of text, but like all exhibits you put on the museum floor, things change over time as you learn how they are used.)

I think the nice, clean, readable type turned out great. I’d still like to see the really varied version that was the first concept some day, but this works for now!

There’s about 650 lines of code running on the Teensy, including code for handling the shift key with every key, so even though you don’t see the exclamation point anymore, you can get one by holding down shift and typing the number “1” key. With the letters you get lower case and upper case, and with the numbers and other non-alpha keys you get whatever would normally show up with the shift key on a standard US keyboard.

In the end, this was an awesome project to be involved in. Thanks to Kathy, Mike, Sam, and Dom for contributing to the entire thing.