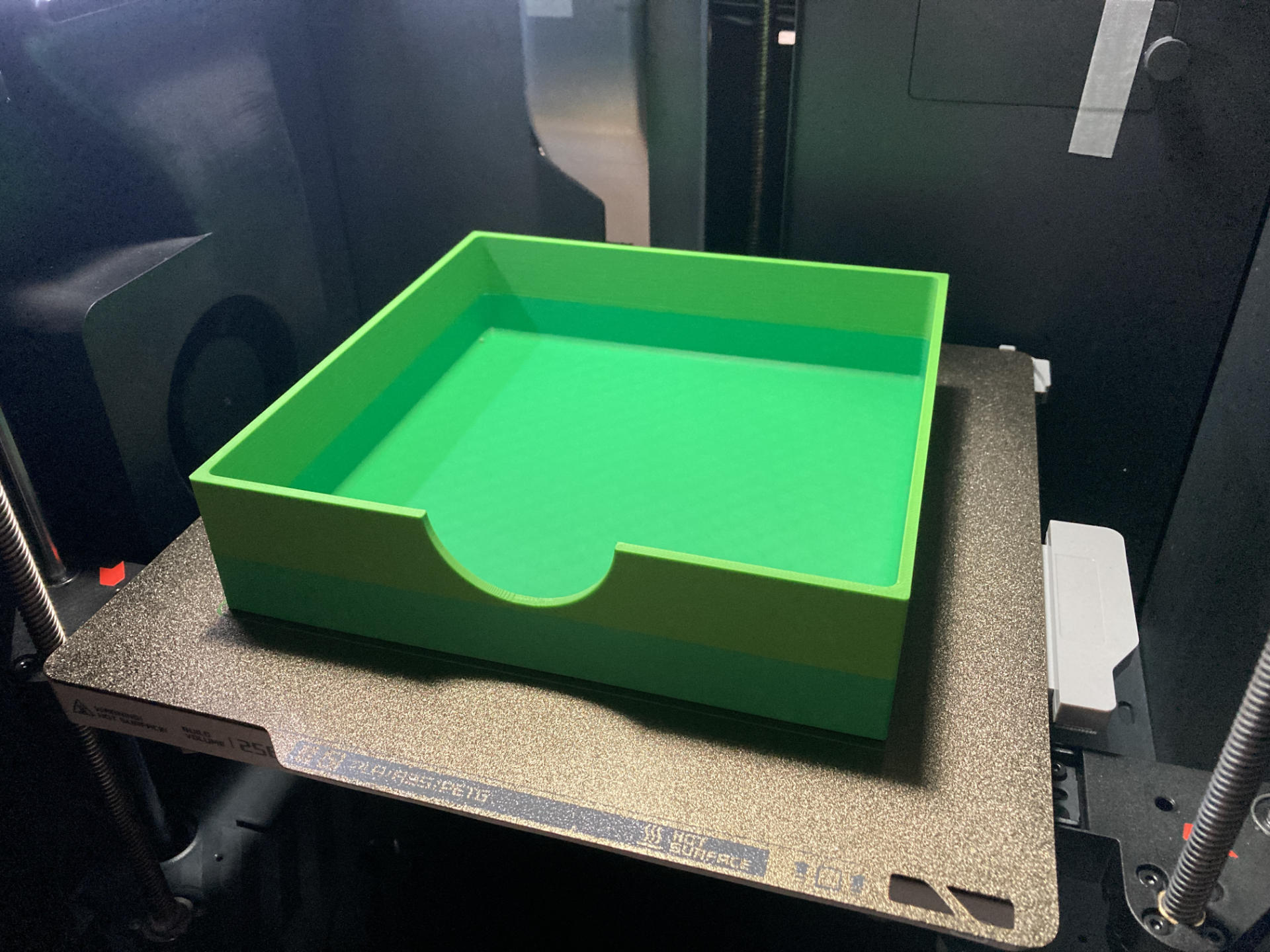

I mentioned Gridfinity a bit in my post about a custom box for hardware, but I’ve also been working on an organization system using Gridfinity for my soldering desk. I’ve got Version 1 done, but of course the beauty of Gridfinity is that it’s modular, and you can make it more modular depending on how you do it.

Usually when you see people print the baseplates for Gridfinity bins they are a large rectangle because they are putting them in a drawer or some other very rectangular area, but I have a weird non-rectangular thing going on, so I printed a bunch of smaller baseplates and bolted them together. The Gridfinity Rebuilt in OpenSCAD library adds some nice features, and one of them is these baseplates with holes, so that’s what I used. (As a bonus I used a bunch of #4-40 hardware I had lying around because I tend to use 3mm hardware for most things.)

As mentioned, it’s modular. So it’s easy to rearrange things, take bins out and move them around, and put them back in place… and they are held into the baseplate with magnets, so they (mostly) stay put. The larger gray one on the left side is my little trash bin. When soldering I put bits of insulation, wire, or any other tiny scrap in there, then dump it into the rubbish bin when it gets full. The rest of the bins are the things I use most often when soldering. I may still make a few tweaks but this is a huge improvement over the cut up cardboard box I was using. The “everything in its place” approach can definitely be a good one.

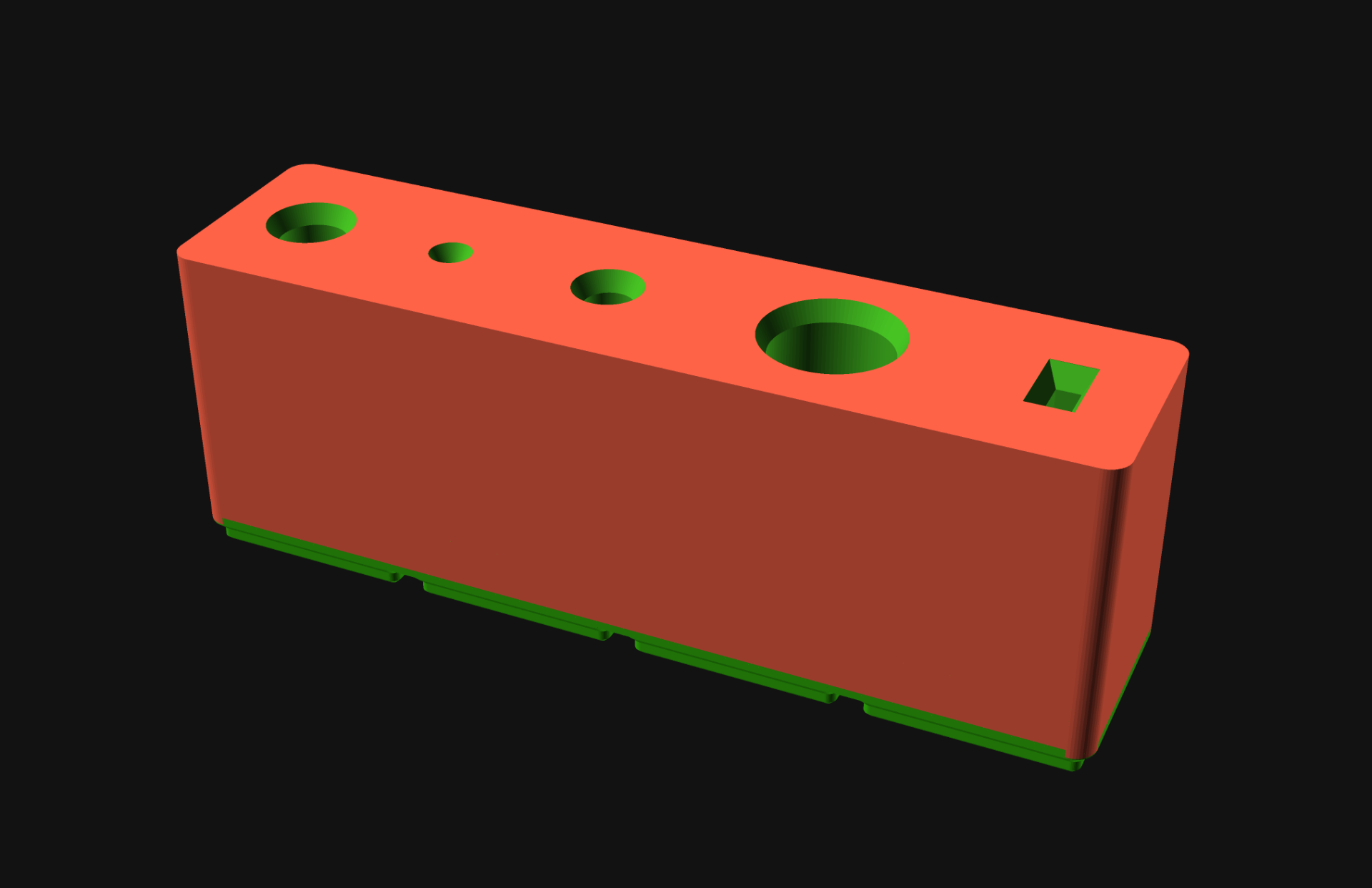

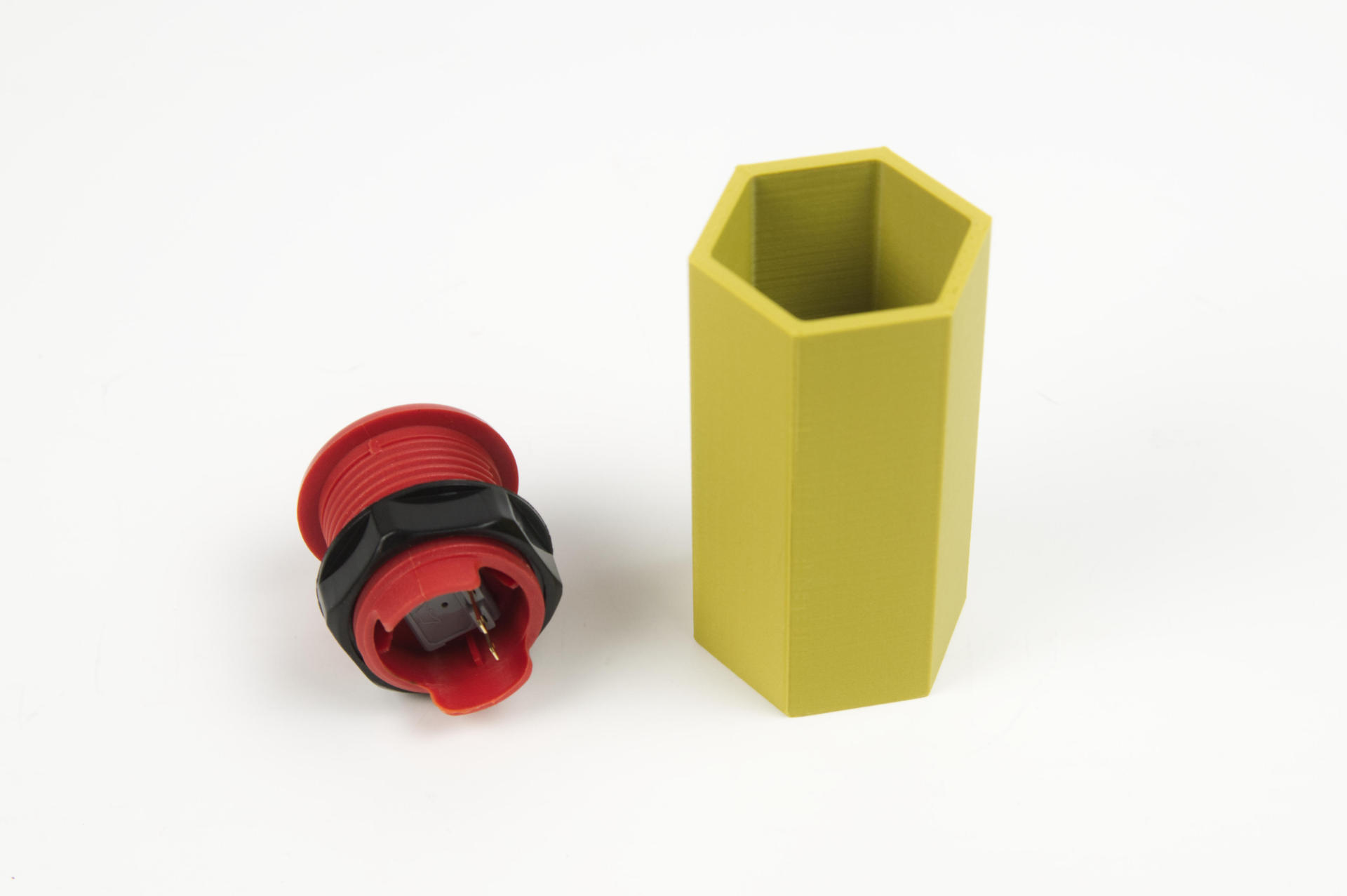

There’s one custom thing here, in the back row, which is inspired by The New Tool Holder but in Gridfinity form. I rushed that piece and didn’t have enough clearance on two of the holes so I ended up drilling them out a bit. It worked fine, but it does serve as a reminder to slow down and get it right.

(I didn’t get a photo of it actually on my soldering desk… if I’m honest it’s still a bit of a mess, just because there is so much on it. If I get it cleaned up I’ll grab a photo and add it here.)