I’ve know about fusing the ends of filament together for at least a decade, but never really tried doing it. Until recently… I tried a few different methods, I did a bunch of reading, watched some videos, and I failed at nearly all of the attempts, or just wasn’t satisfied with the results. But somehow along the way I absorbed enough information to try something, and hey… it worked!

Note: Just want the files? Get them from Printables.

I read a lot of posts, and watched a lot of videos, and I feel that it’s sort of like 3D printing itself – what works for one person may not work for another – so find what works for you and go with that.

The method that is closest to what I did can be found on the Filament Splicer & Joiner with Roll Holder page. Rather than go through all the trouble of printing those parts and assembling it all, I took a simpler approach and went minimal to test things out.

The Tube

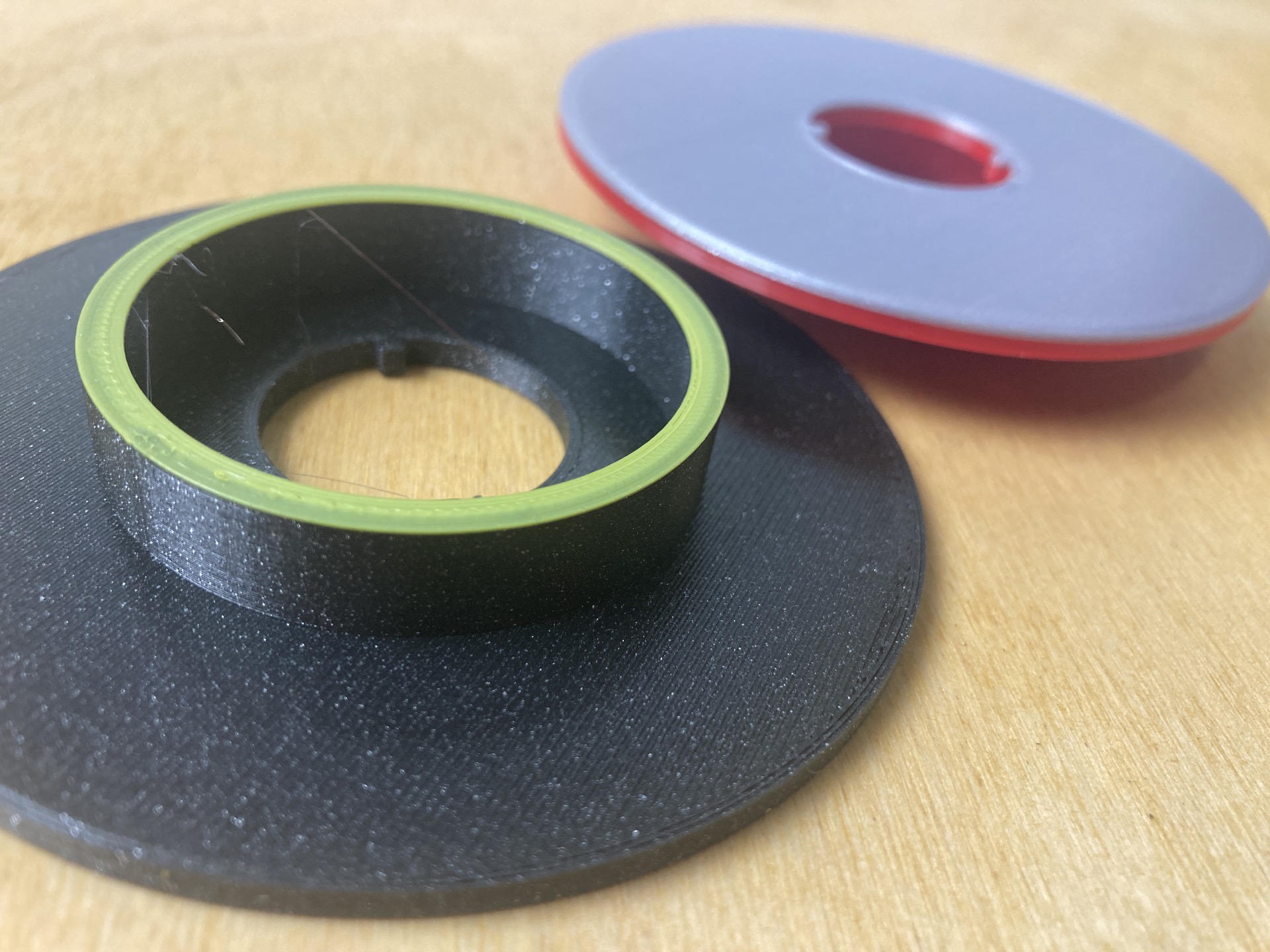

I ended up using this PTFE Tube (which is 1.775mm~ ID / 2.5mm OD). Wait, why is this important!? Most PTFE tube used in 3D printers (to feed filament to the machine) is 2.0mm ID / 4.0mm OD. Many methods use this size tube, and the issue is that the filament expands to 2mm inside the tube. The recommendation is to then shave and/or sand down the filament to get it back down to 1.75mm. This method constrains the filament to a dimension much closer to 1.75mm.

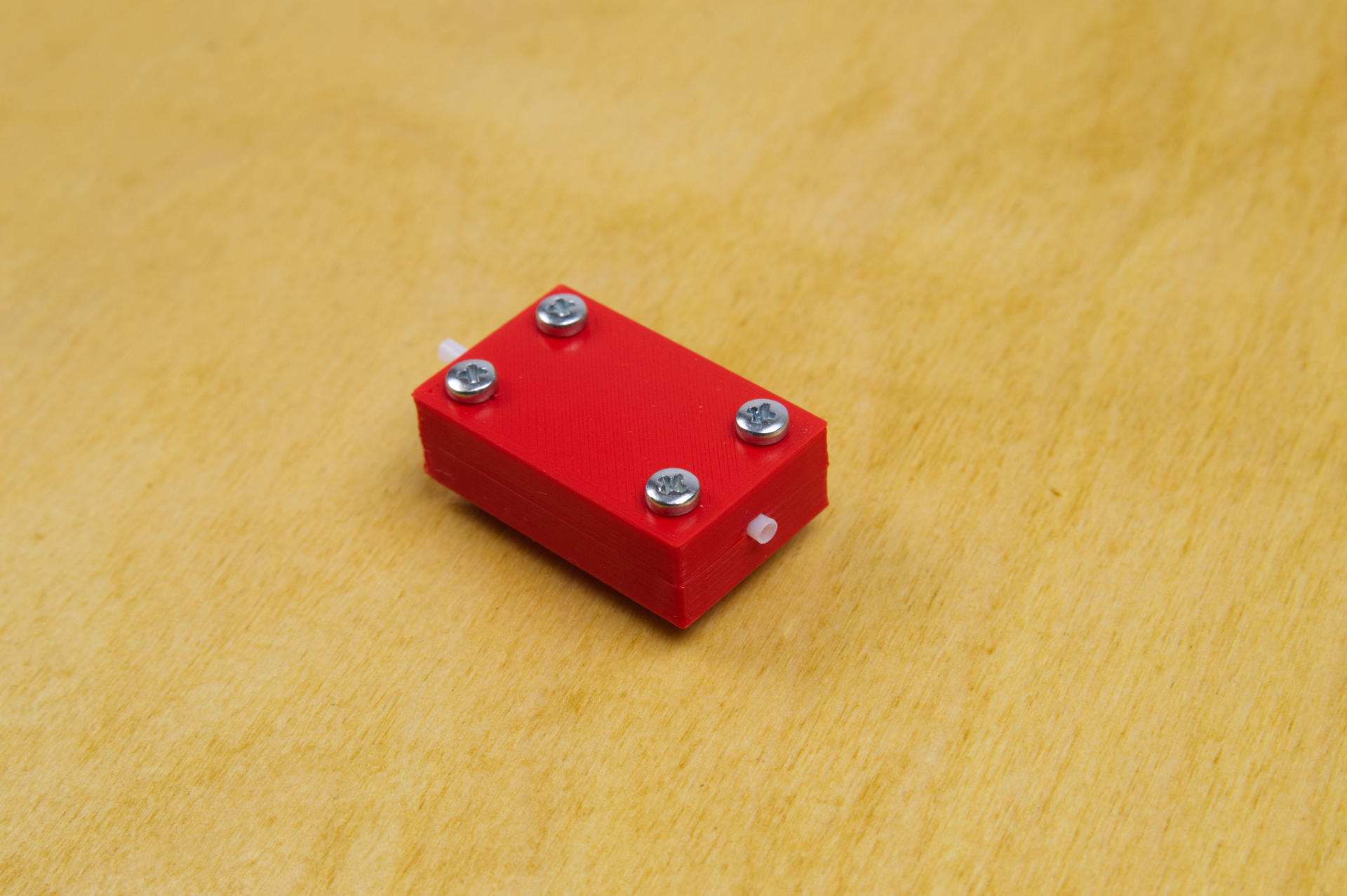

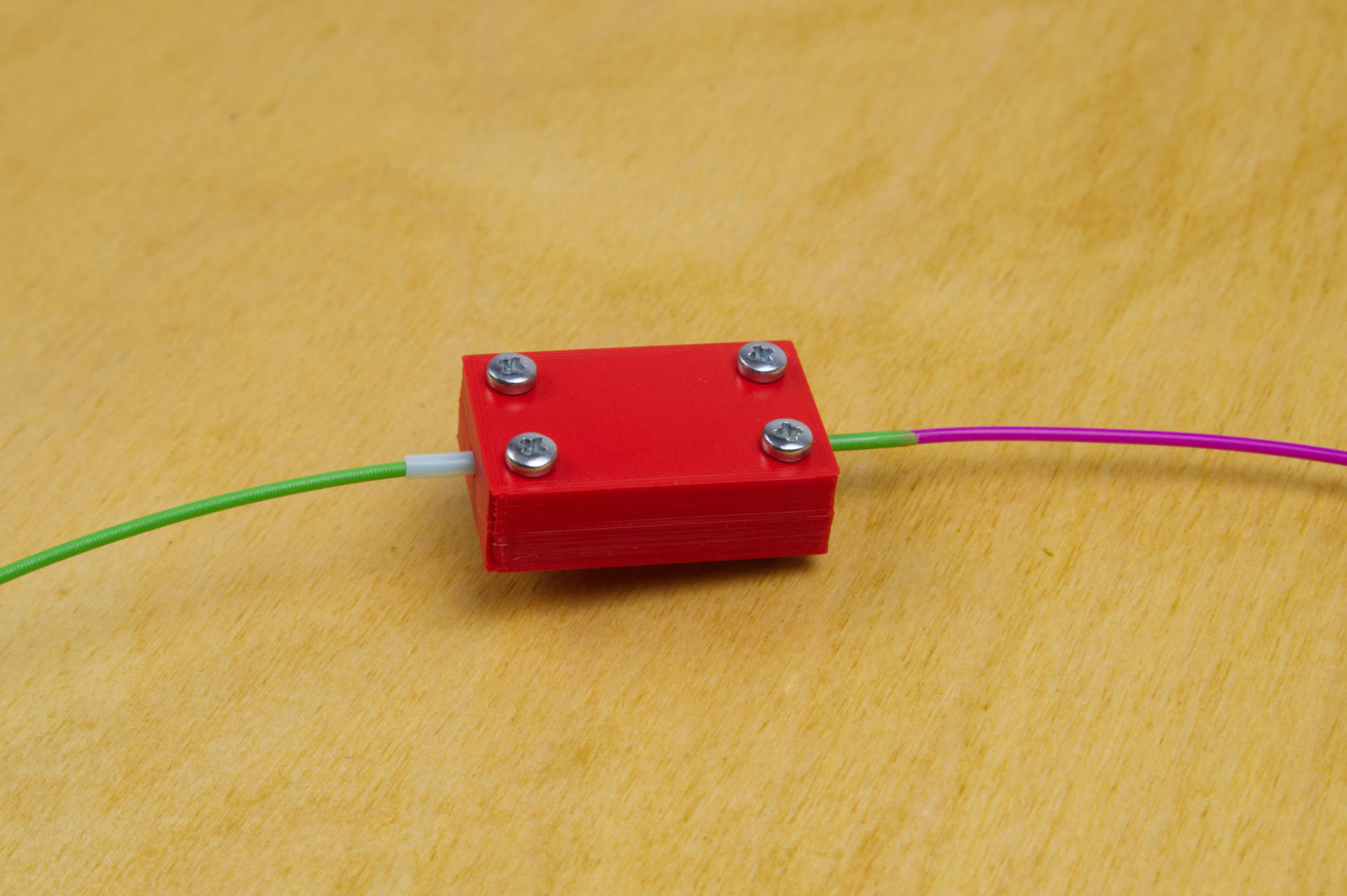

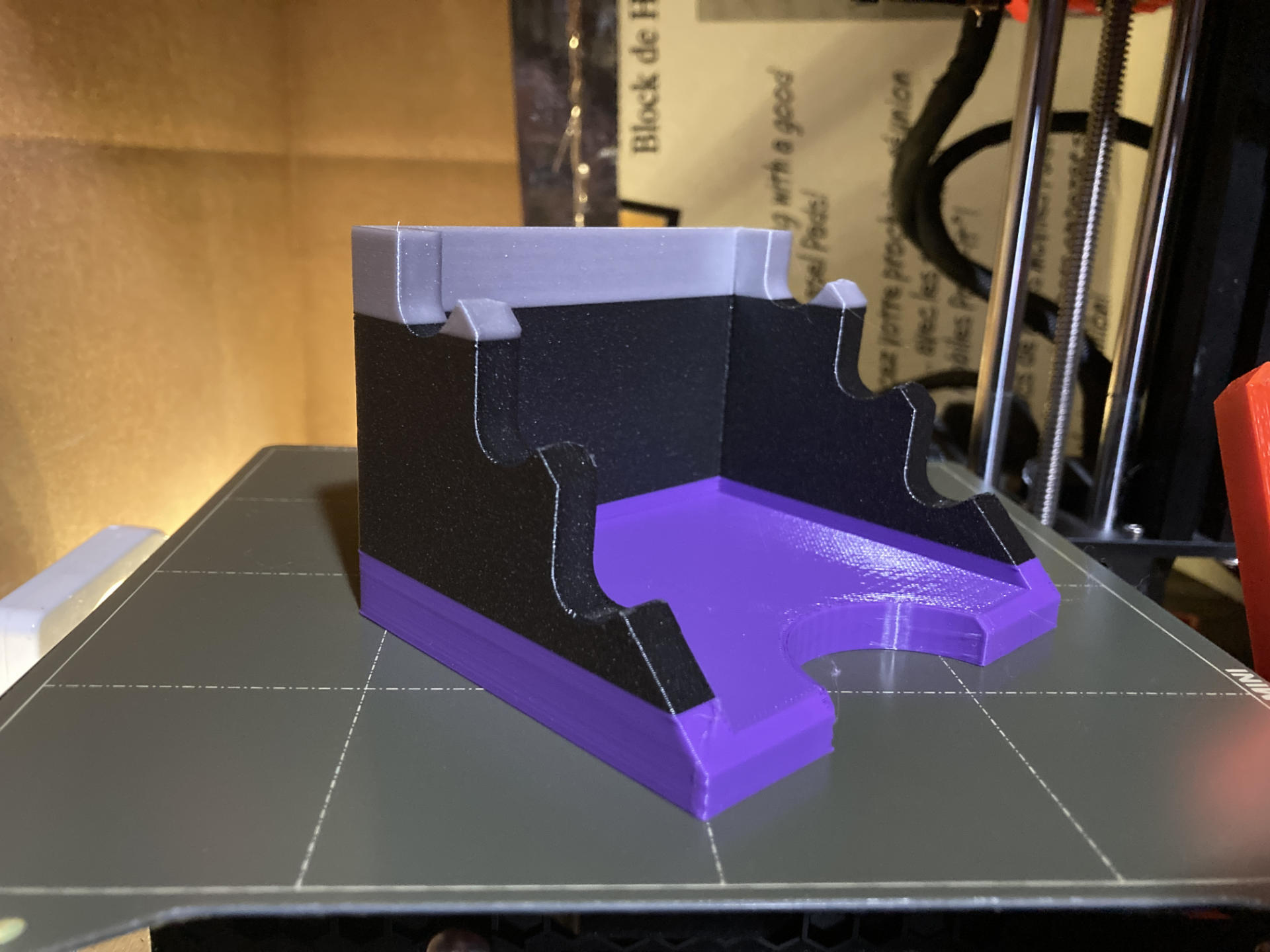

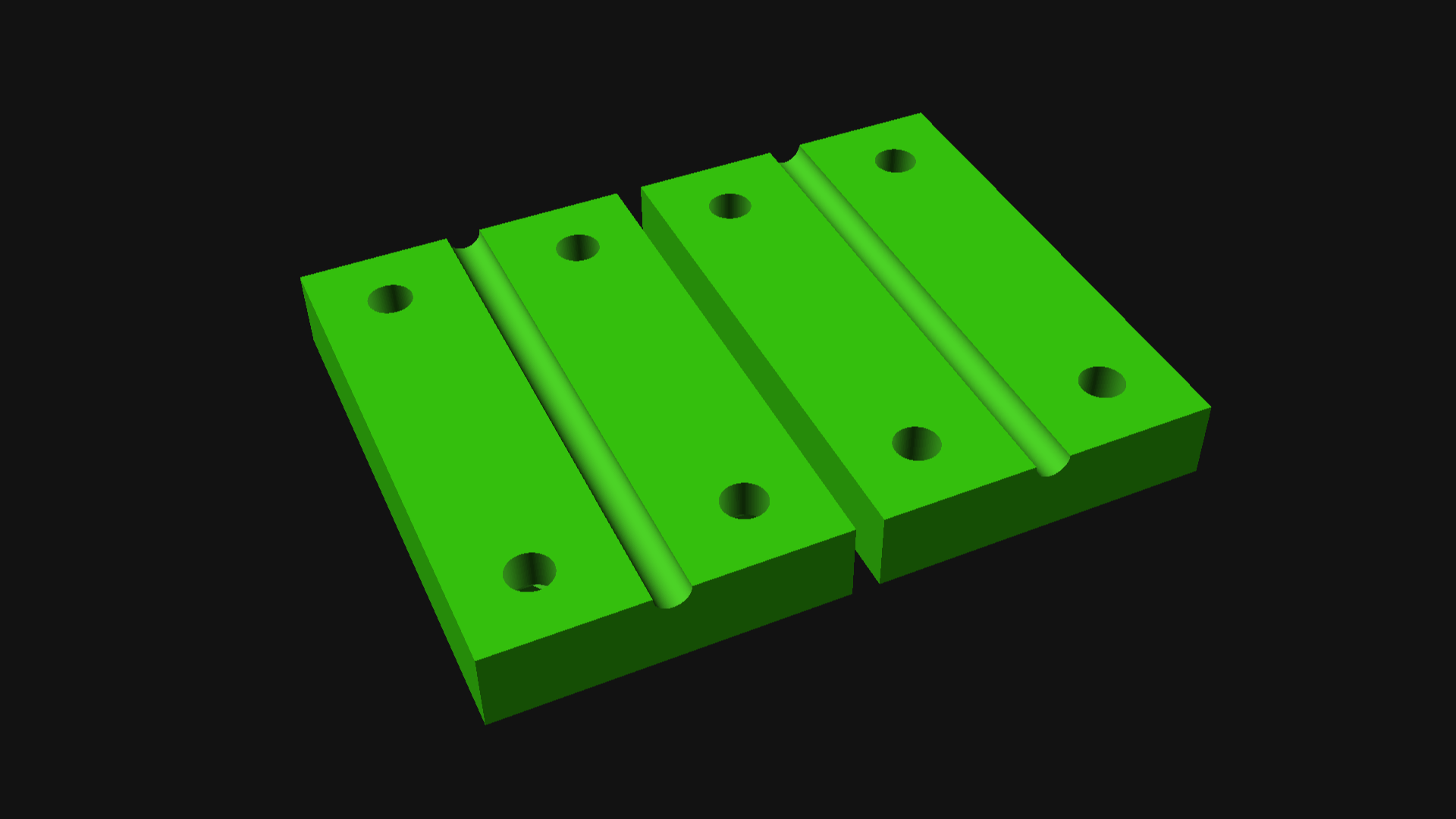

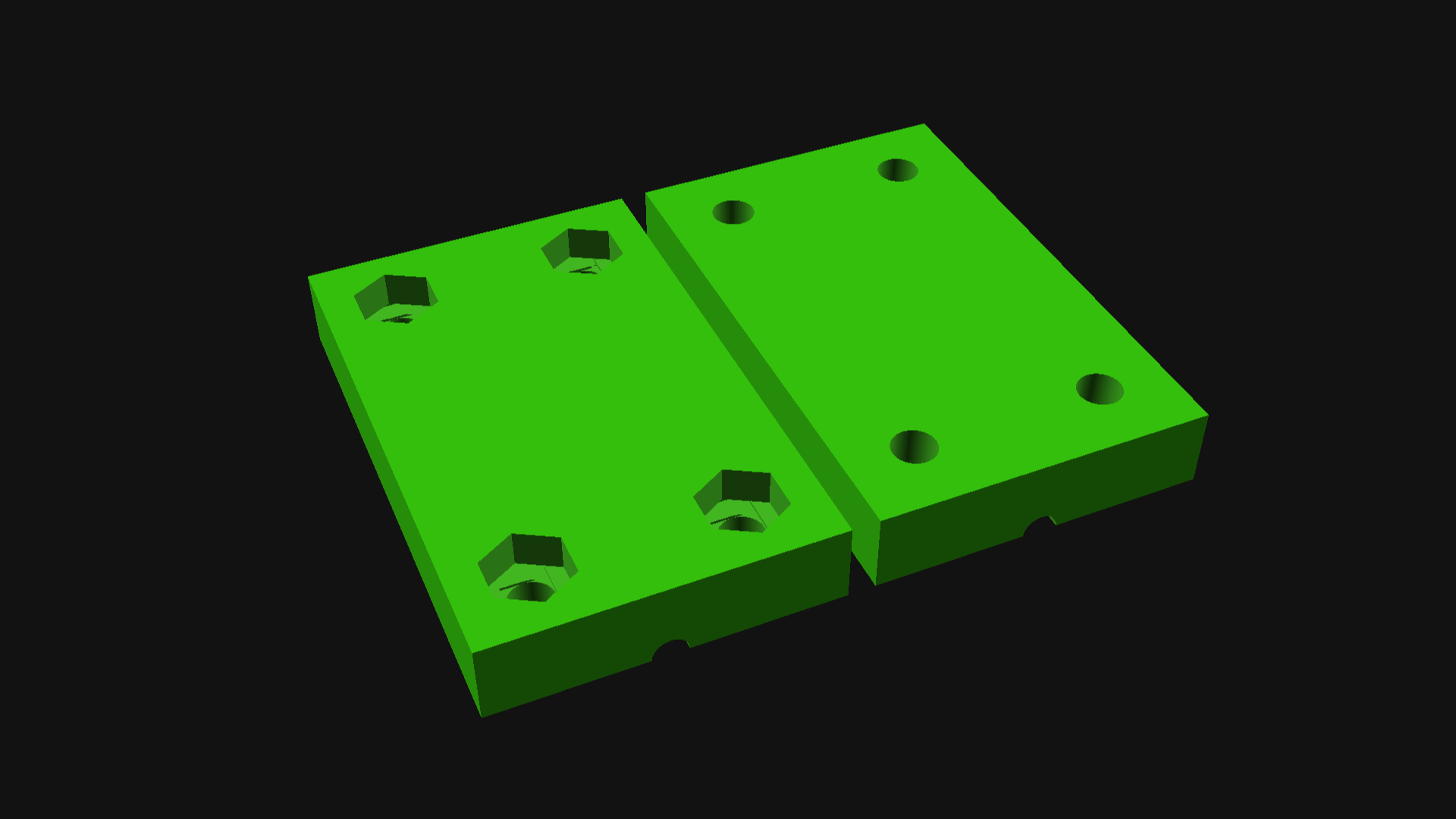

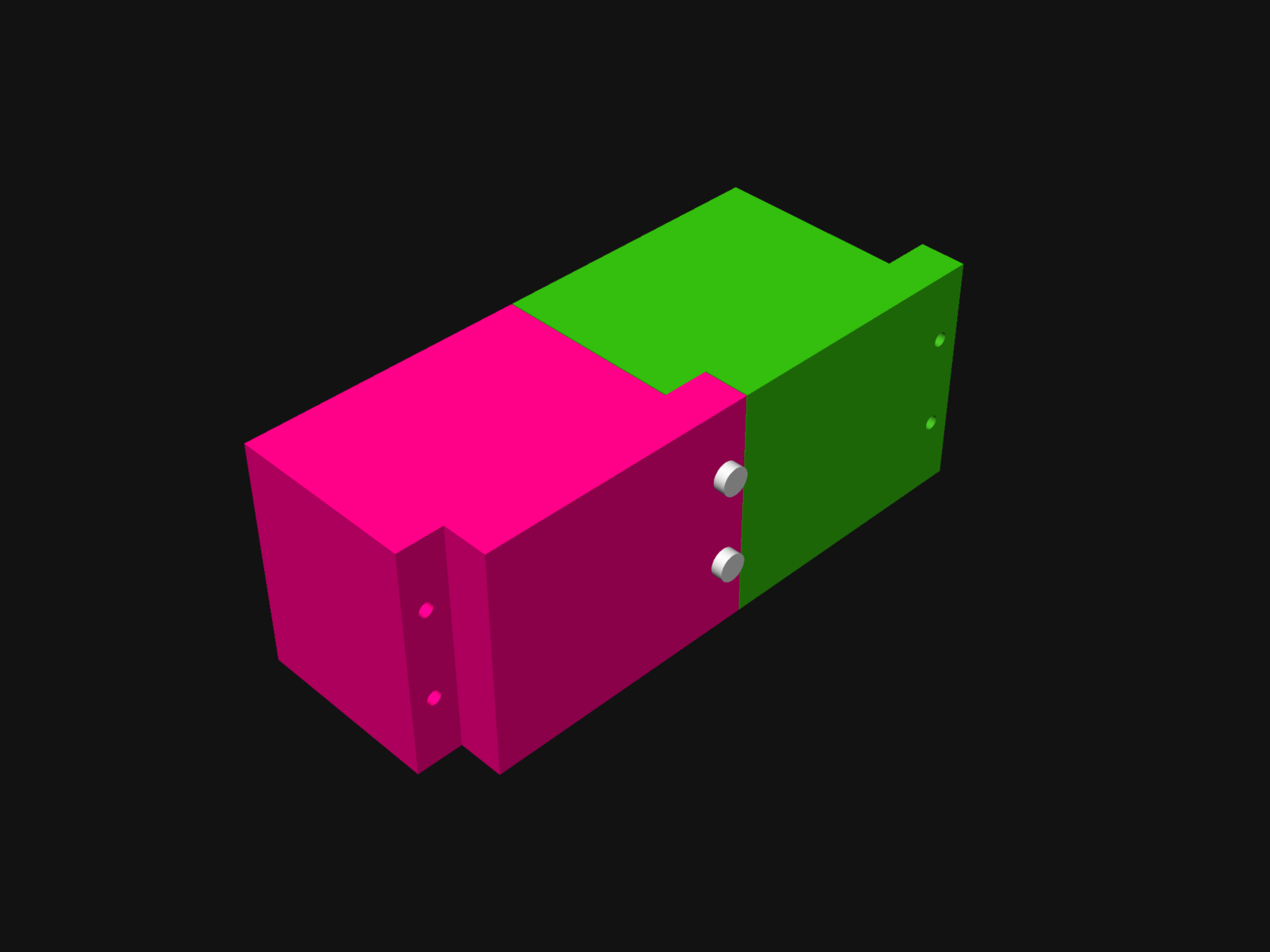

Besides the tube (which is the most crucial part of this whole thing) I designed and printed two parts and added a few 3mm bolts and nuts to hold it all together.

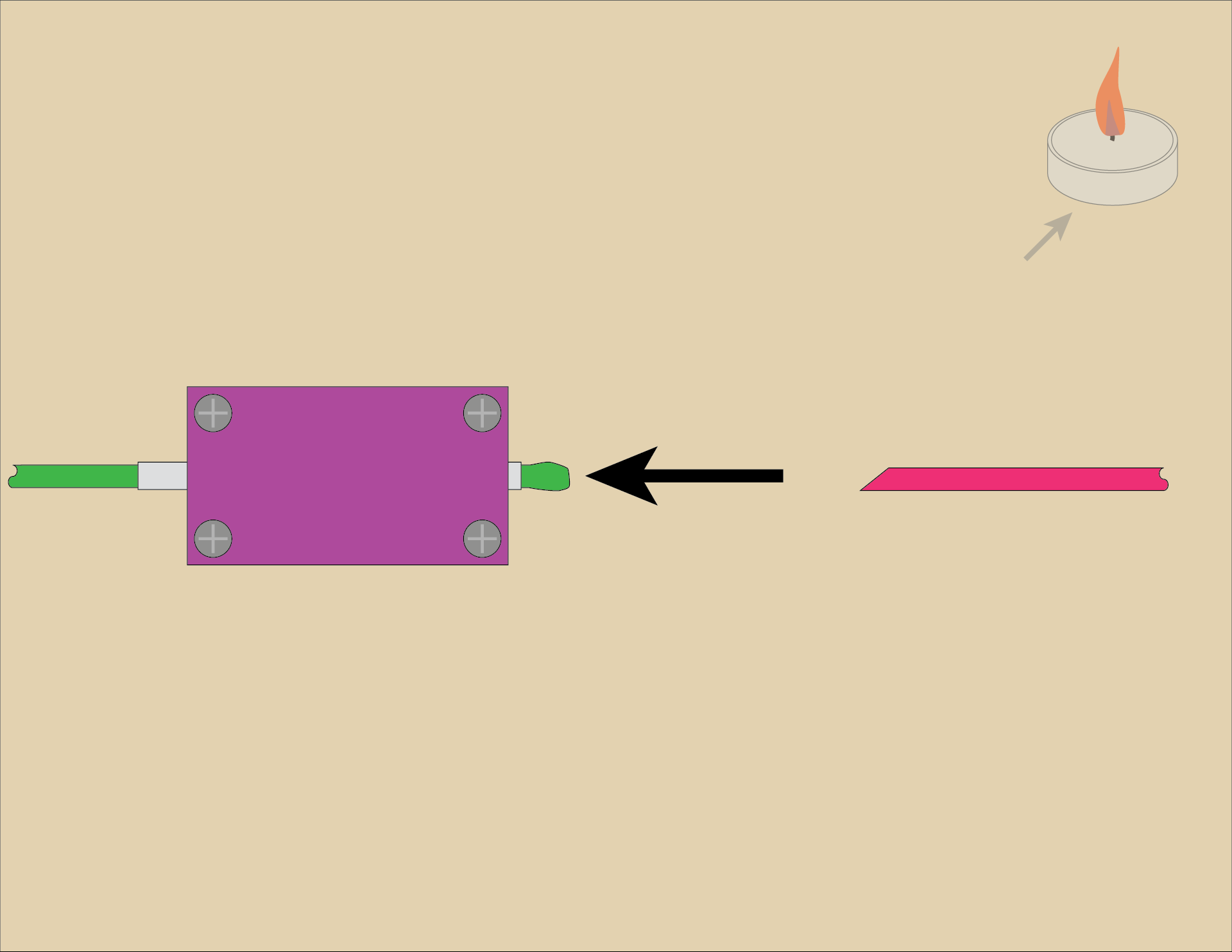

You’ll notice a long end and short end of the tube sticking out of the device. You’ll want the short end to be the business end. I probably could have trimmed the tube down on the back side but it’s okay to be a bit longer. Just keep the other end barely sticking out as shown.

I also used a vise to hold the device securely in place (I can see why Turnt use a clamp design) and also grabbed a candle… and of course, some filament!

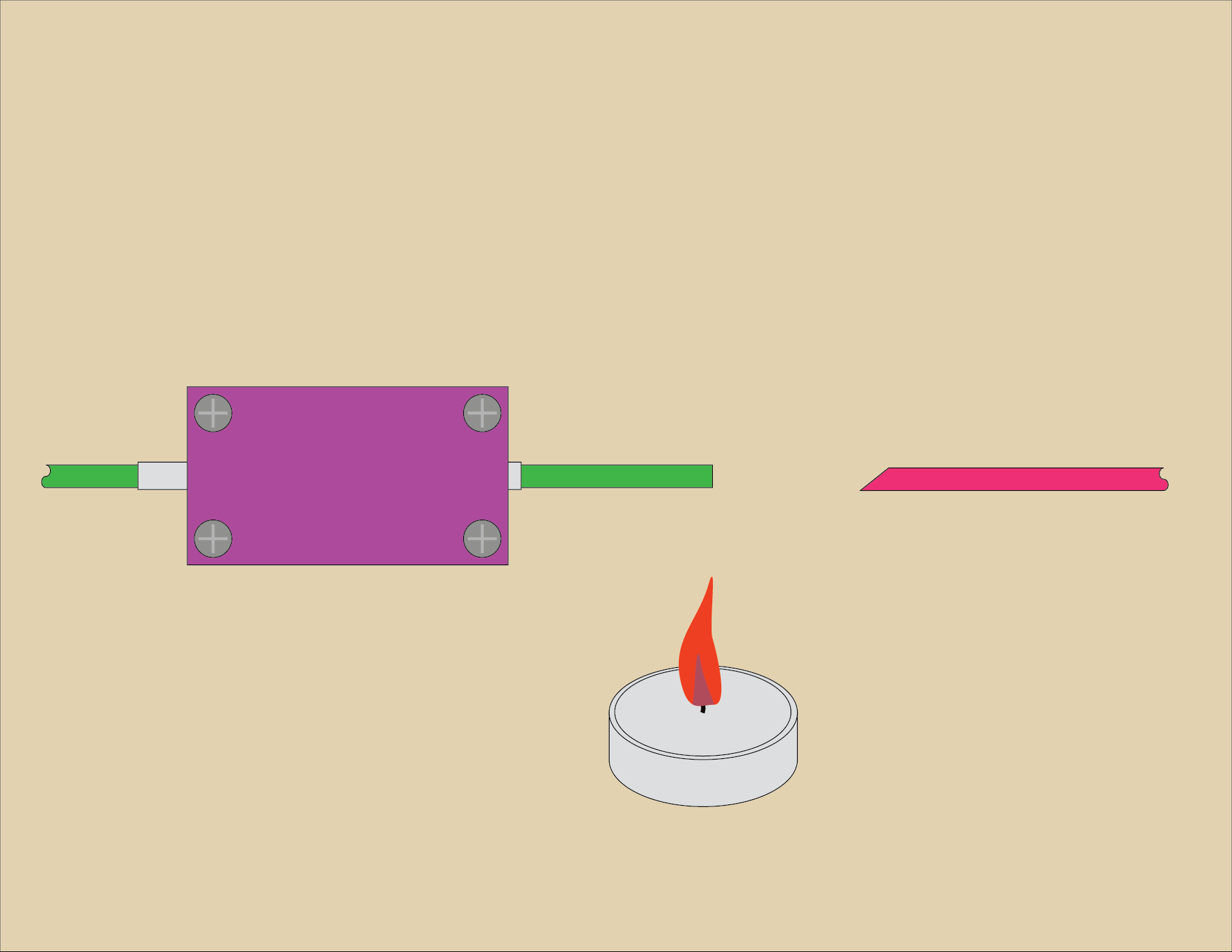

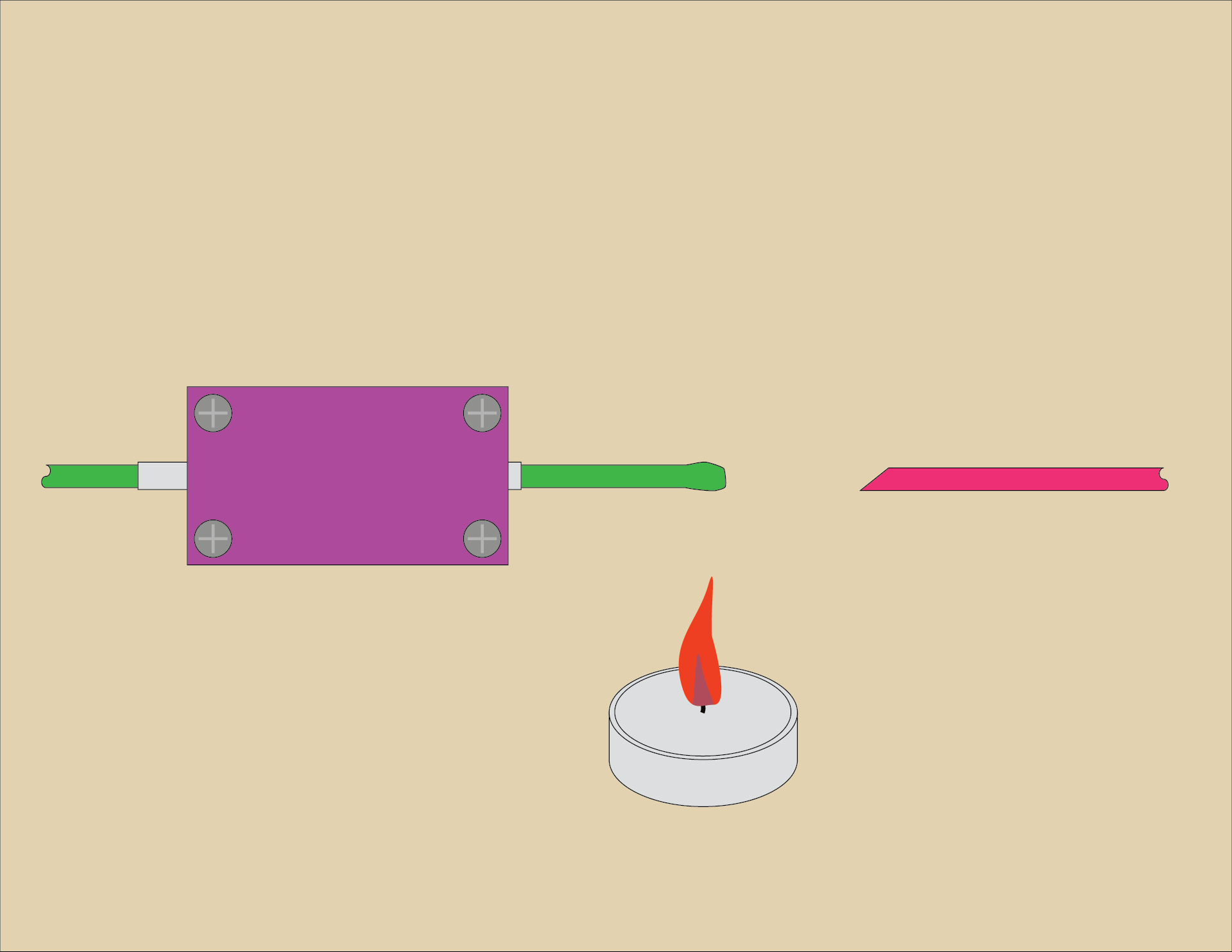

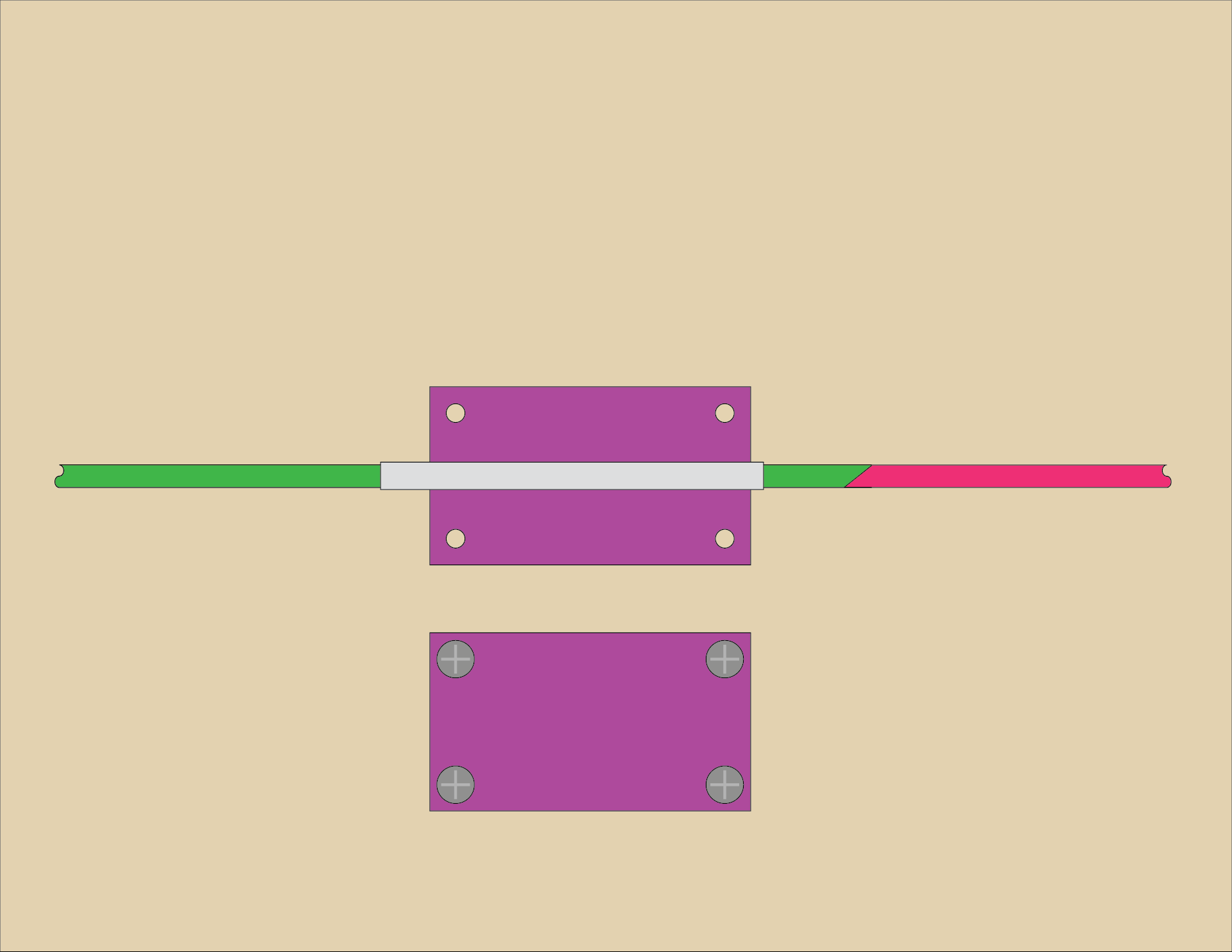

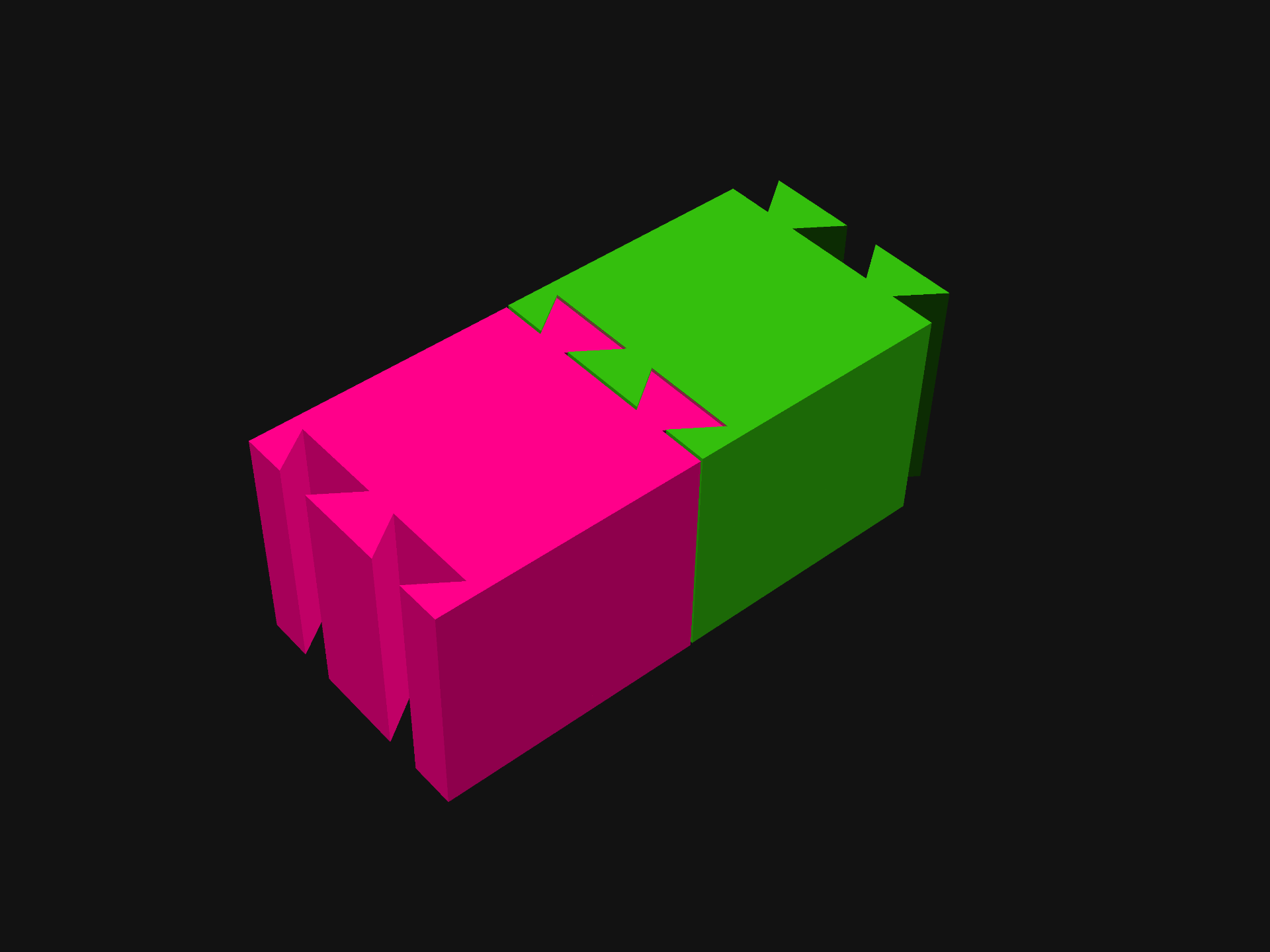

I’ll try to produce a quality video but in the meantime here’s an illustrated guide demostrating the technique. (And yes, I did mix up the colors as compared to the photos! You also won’t see the vise in the illustrations, so just pretend it’s there.)

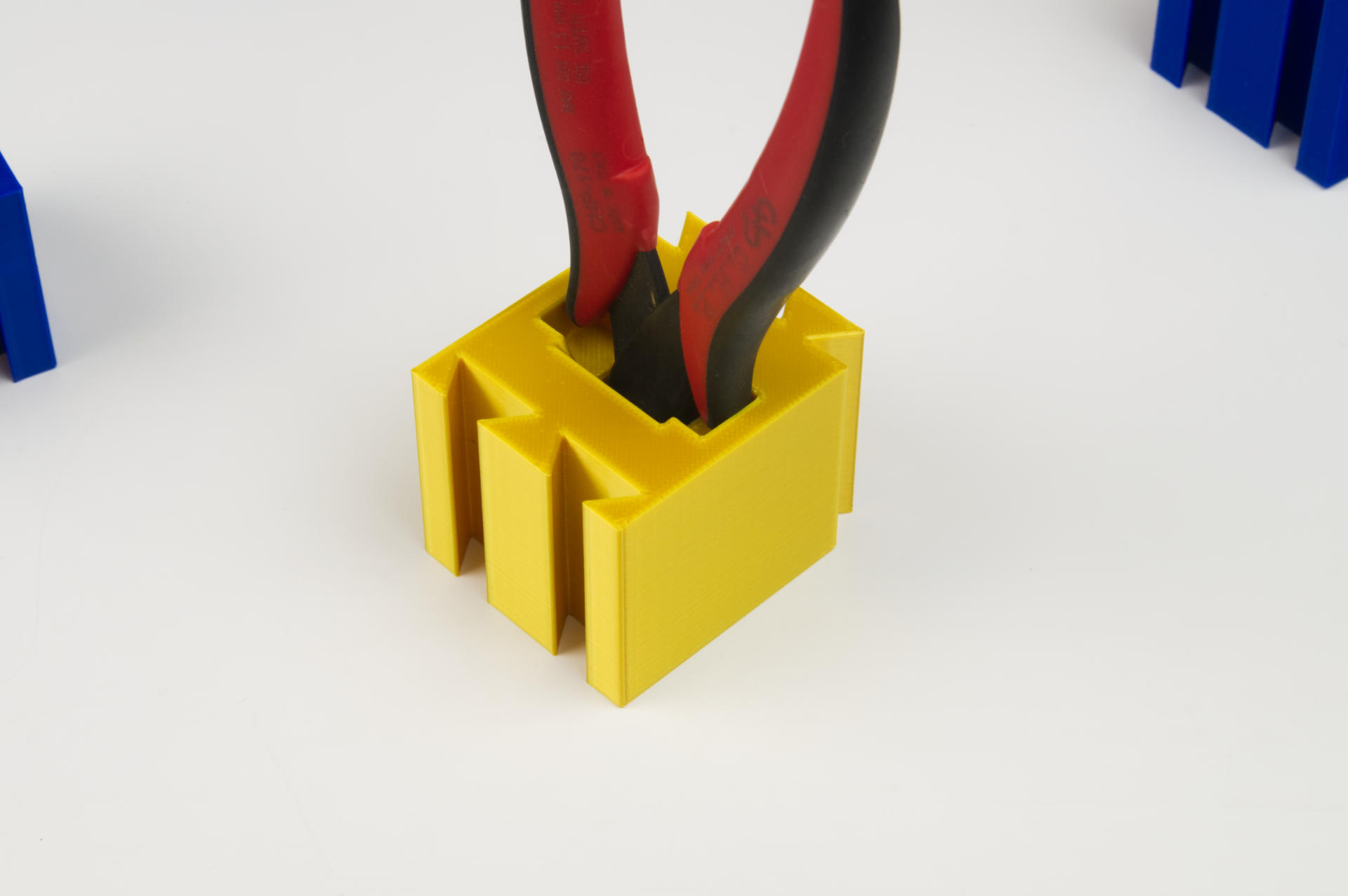

Insert a piece of filament from one side and slide it all the way through. It should have a flat cut end on it. This is the piece we will heat up. The other piece (on the right side) should be cut at a 45 degree angle. The angle is primarily to allow you to quickly and easily feed it into the tube without fiddling about.

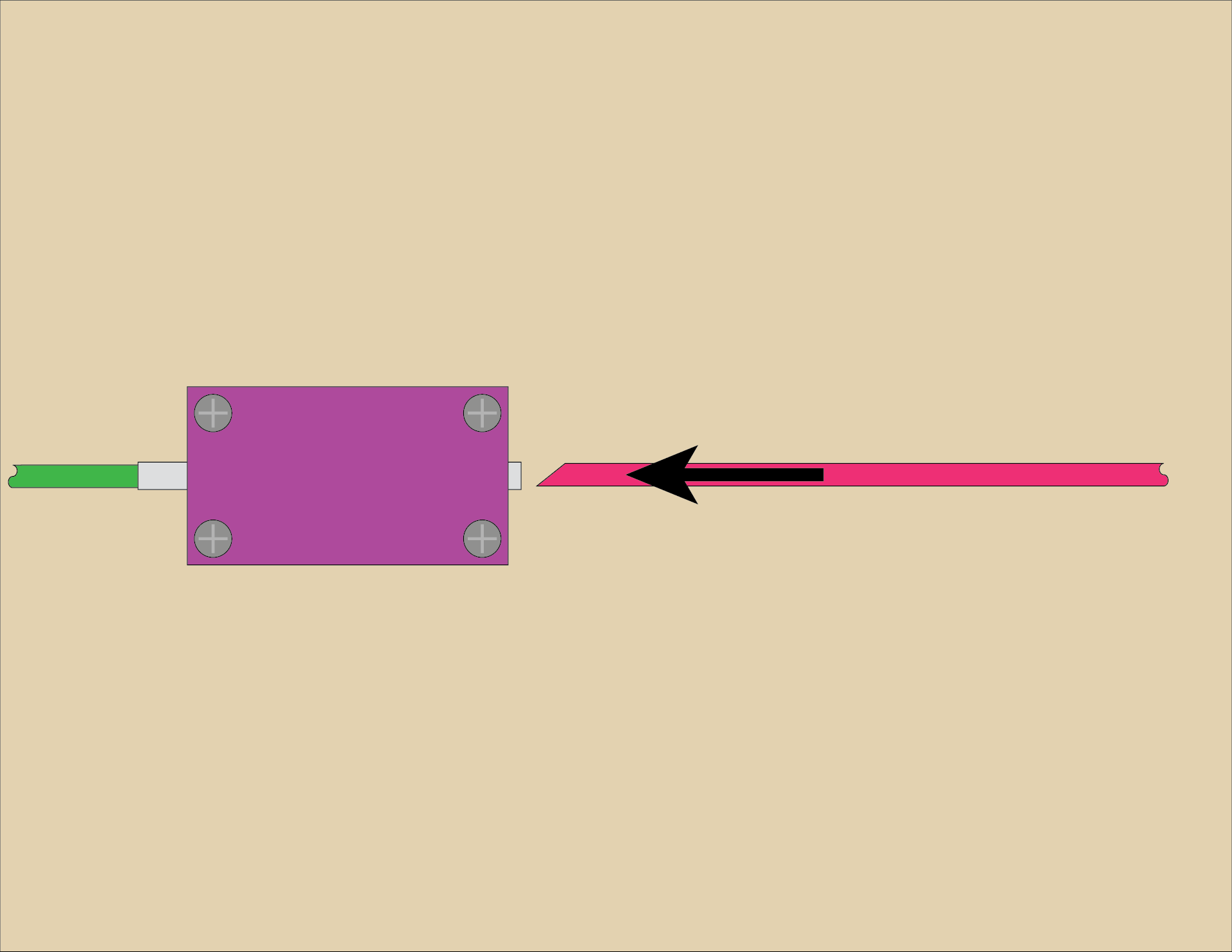

Put the filament over the candle flame and it should start to soften. Don’t get it too close, or it will catch on fire and burn! Start with the filament further away from the flame and slowly move it closer. I think around 100mm is a good starting point.

Once you see the filament end soften into a blob pull it back into the tube… You’ll need to pull it in about halfway into the device. Practicing a few times will help you get it right.

At this point you may want to move the candle out of the way, or just blow it out for safety.

Once you’ve pulled the heated filament into the tube quickly push the other piece of filament (with the angled end) into the tube.

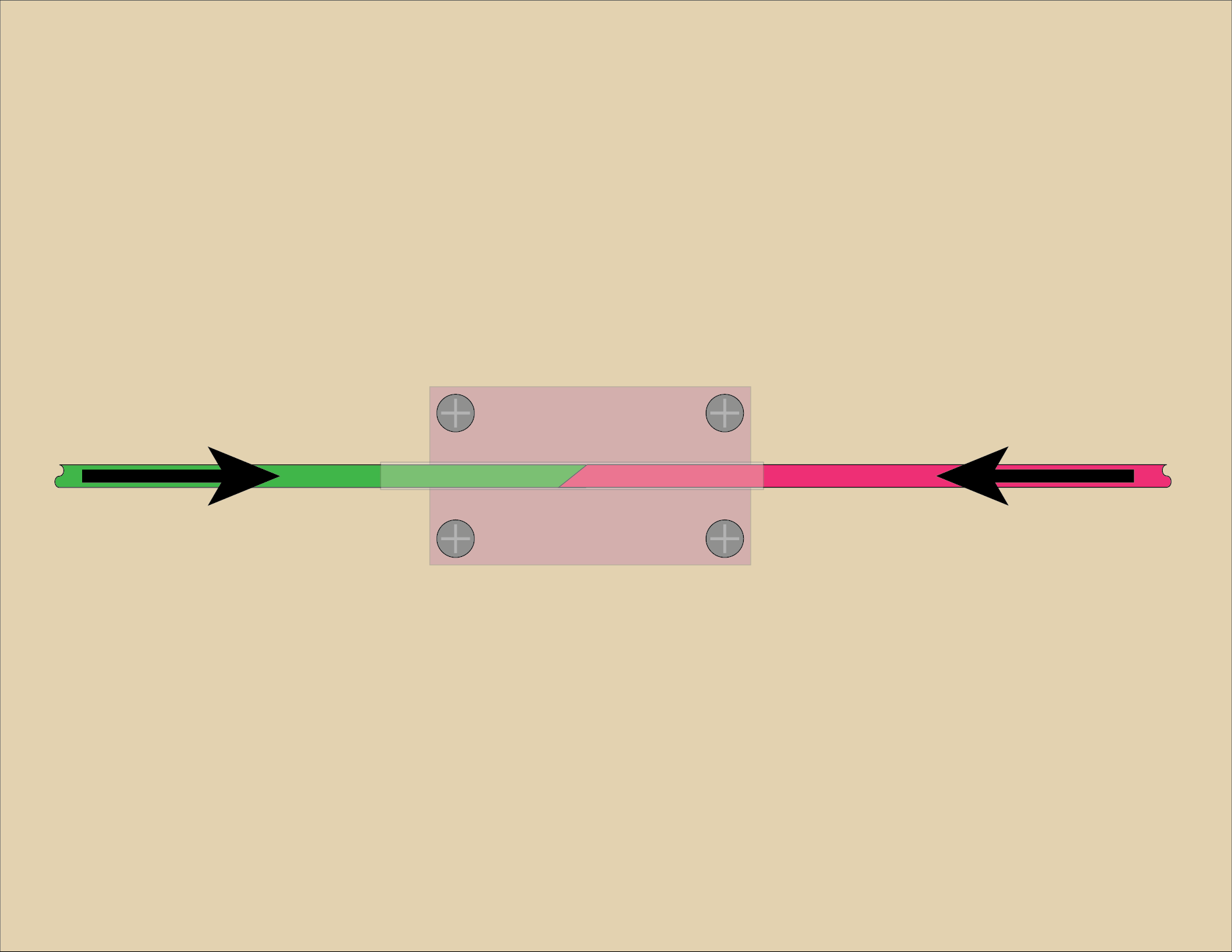

Now you should be using both hands, holding both pieces of filament, pressing them against each other. Push and hold. You don’t need to push with all your might, but give some good pressure. Wait a bit for it to fuse and then cool… 30 seconds should do it.

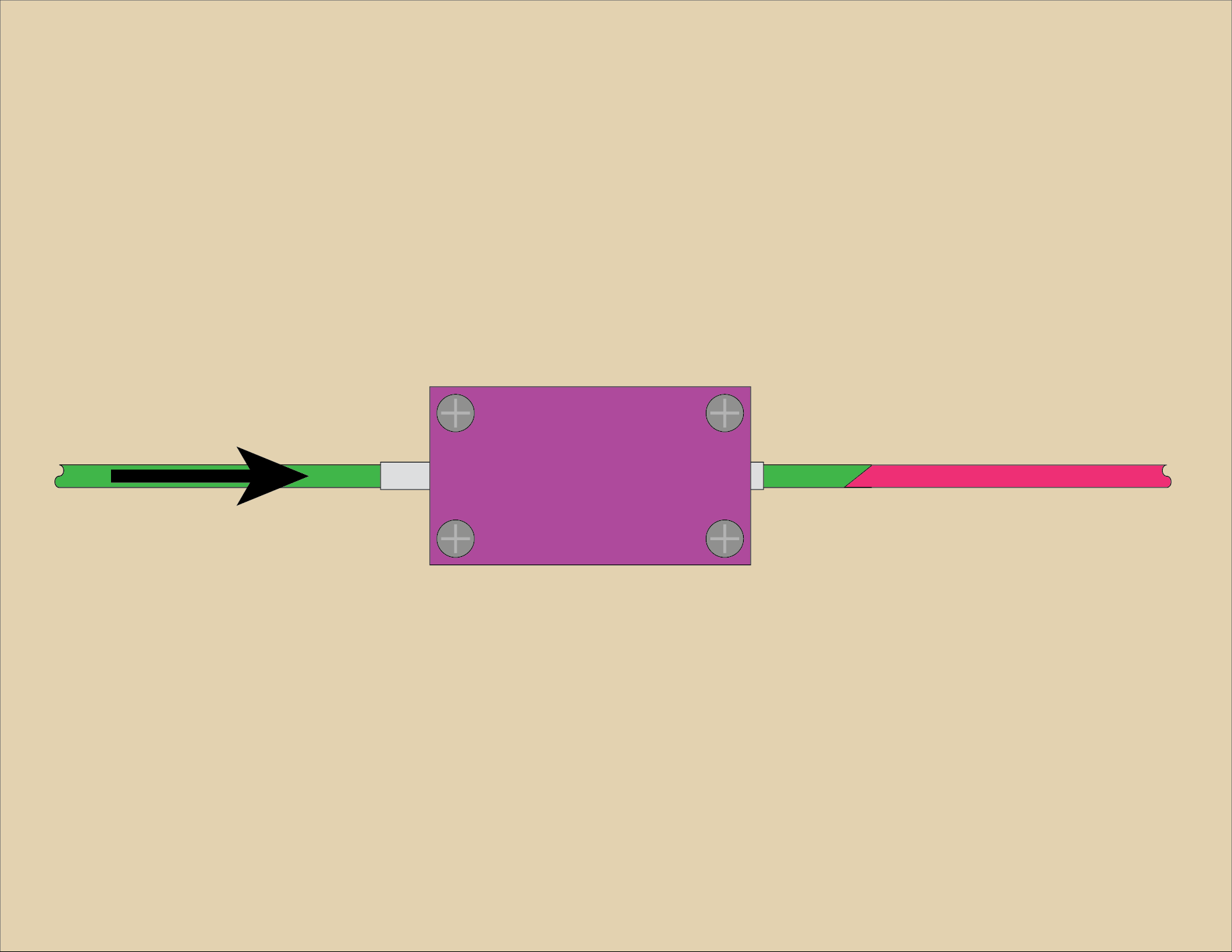

Now push/pull the filament out again, and inspect it. Give it a (light to medium) tug to make sure it doesn’t come apart. If it separates, cut the ends and try again.

If you find that you cannot push/pull the filament out of the tube you can loosen the screws to release the clamping on the tube, or separate the top and bottom pieces completely so the tube can be removed from the assembly. This can make it easier to slide the filament out. You will obviously have to slide the tube completely off of the filament piece. When doing this I’ve probably got a spool on one end so I’ll slide the tube away from the spool to free it from the filament and then spool it all up.

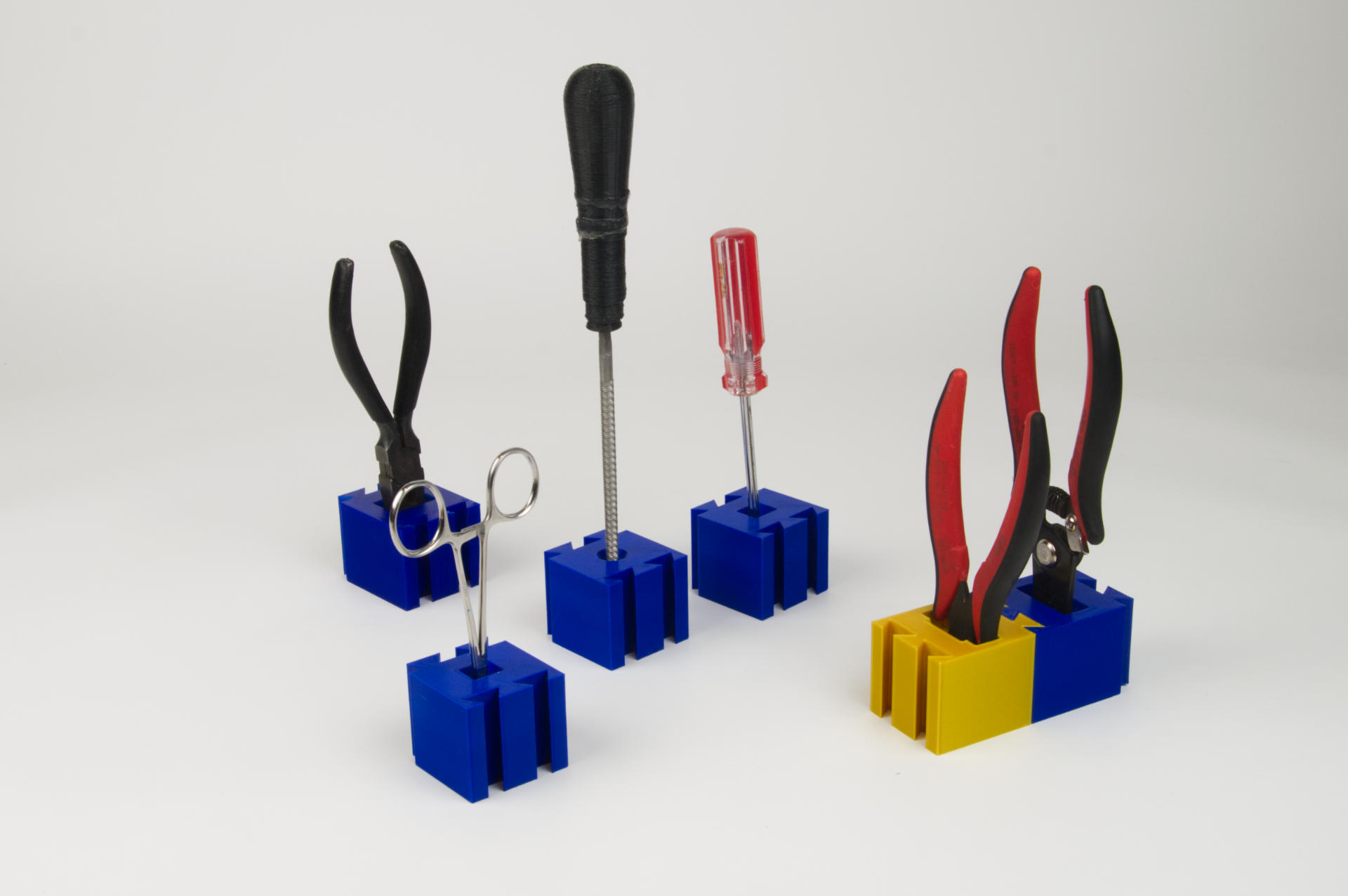

Using this method I joined about a dozen pieces of filament into a portion of a spool and then did some test prints. Are they the greatest prints ever? Probably not… Since I mixed multiple colors and brands together I’m sure the filament profile, which should be tuned for a specific filament, sort of goes out the window. Still, the results were completely acceptable and I’d rather find a way to use up all those short bits and unspooled samples I’ve collected over the years.

The Device

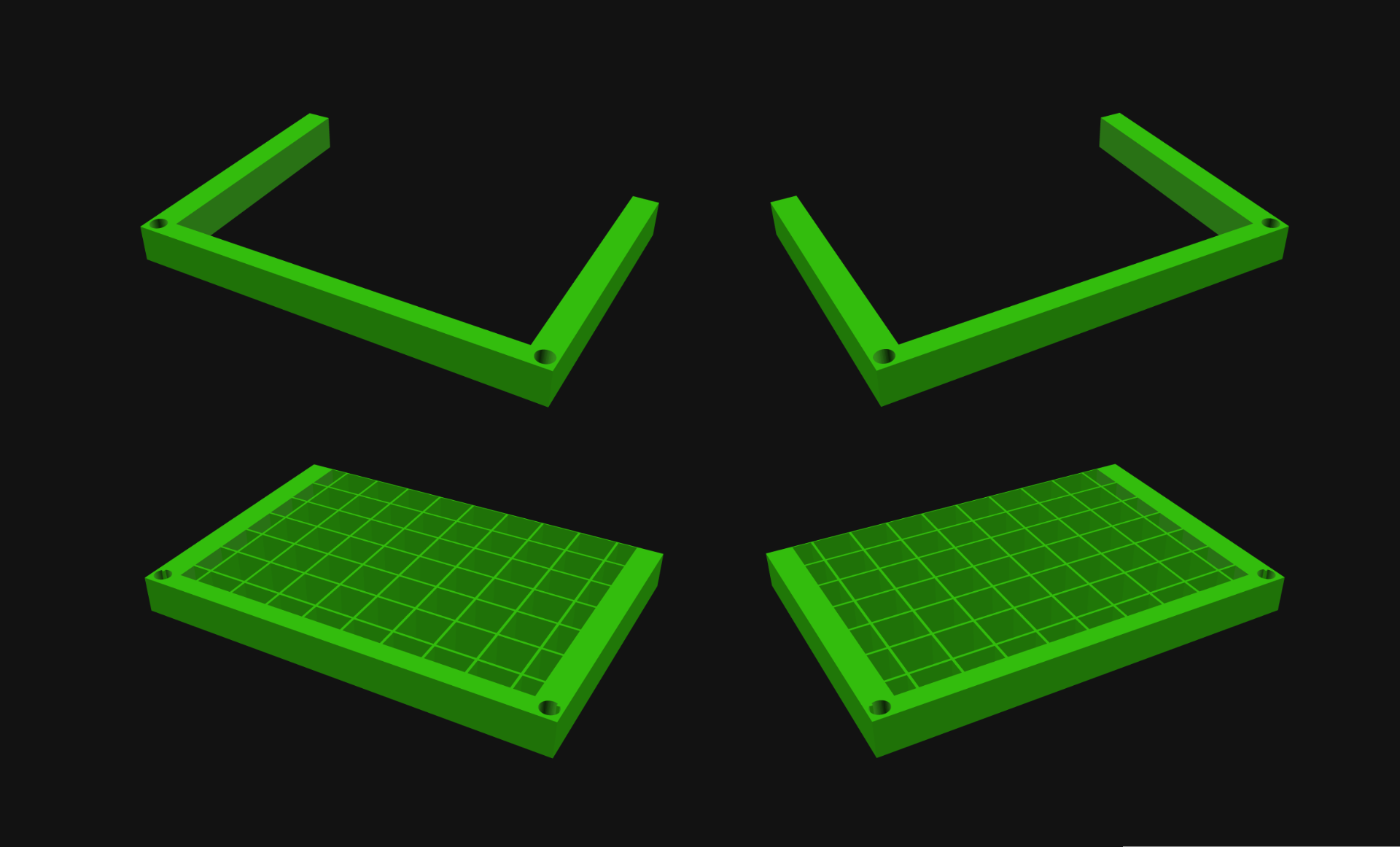

You can get the STL and .scad files from Printables.com – Simple Filament Fuser. Print it if you want to give this a try…

You’ll need four 3mm x 14mm (or longer) bolts and four 3mm nuts to assemble the device. You can probably use #4-40 bolts & nuts as well, or adjust the size of things in the .scad file to suit your needs.

If you end up making this and using it, please let me know. Did it work? Did it not work? What was your experience? Any tips or tricks to share?

Update: Don’t like the DIY route? This Filament Welder device is somewhat similar, but reading the reviews suggest you will need to shave/sand down your joints, and you may also benefit from a few of the tips I’ve shared in this post.