One of the pieces I needed for my turntable drawing machine was something to hold a bearing in place underneath the platter to support it and let it spin easily. If you’ve ever taken the plate out of your microwave oven to clean it you may have seen a “Microwave Roller Wheel / Turntable Support” thing. (Really, that’s what it’s called. Check Amazon.)

I decided to use 608 bearings, mainly because I had a lot of them on hand, but they’re also really easy to get for a low price. (I think I got 30 608ZZ bearings for under $20 from Amazon.)

I designed these two arms that would fit into slots cut into the base of the machine, below the platter. Each piece would be locked into place with a 3mm bolt, so there’s holes and t-slots for those. The extra piece you see on the bottom (with the 4 slots and 2 holes) is the mating piece. This was designed based on the arm pieces fitting into it, and I would only need to cut one (hopefully) to test the fit.

The arms are slightly different. The one on the right has a hole large enough for the 8mm bolt to fit through, while the one on the left has a slightly smaller hole. The plan was to tap the smaller hole so the bolt could screw right into it without needing a nut. Do a search for metric tap drill size and you’ll see that a 6.8mm hole is needed to tap it for an 8mm bolt. (Sometimes you can just look on the tap and it’ll tell you what size to make the hole.)

As a bonus, when I share the files for this you can decide which pieces suit you better, depending on the availability of an 8mm tap in your workshop. No tap? Just use the larger hole version and a nut instead.

When you’ve got a laser cutter and lots of scrap acrylic, it makes a lot of sense to make your own washers and spacers and standoffs. (Assuming acrylic is up to the task of what you’re designing.) The spacers were sized to match the inside part of the bearings allowing the outer part of the bearing to spin freely.

I originally was going to make acrylic nuts as well, but decided on tapping the holes with threads. I still wanted the “hex nut” part of the design, as it’s used to hold the platter in place. So that, in conjunction with the tapped parts, prompted me to make the hex shape at the top of the arms. (It’s the details, right?)

The one thing that making and using acrylic nuts would have allowed would have been adjusting the height of the bearing. I could have created a slot for raising or lowering the bolt and bearing combo, so with this design featuring the tapped holes, there was no room for adjustment. Luckily I got it right by the second (or third) attempt.

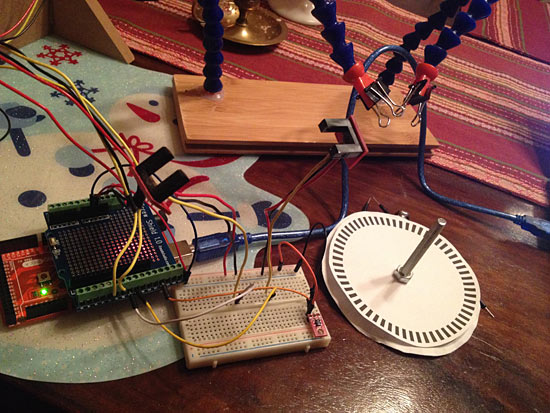

Here’s a shot of the spacing of the bearing holders below the platter. It worked out well and I got the math (mostly) right. I may end up making a new bottom in the future to account for other faulty measurements this time around, but I’ve already adjusted for them and things work well enough.

(For other posts about this turntable, check the posts tagged with dcrlmtm.)