So back when I first used the MakerBot at Milwaukee Makerspace, my daughter asked me to make her a cow. (The kid likes cows!) Since my 3D modeling skills were not up to the task (and still aren’t, at least not for a cow) I found a cow in the Google 3D Warehouse and brought it into Sketchup.

It looked fine, so I exported it as an STL file and did a print. A very small print. It looked OK (but not great) and since it was small there wasn’t really much detail.

Since then I’ve looked at other files in the Google 3D Warehouse, but since most of stuff there is for screen display and not 3D printing, things tend to be very complex, at least in the well done models. More complex than might be needed for a 3D print, at least from the Makerbot.

I’m still pretty new at this 3D modeling stuff, but simplifying the model seems to be what we want. In the 2D world I’ve been doing the same sort of thing for 20 years, but in 3D? It’s new ground.

Enter MeshLab!

From the MeshLab web site: “MeshLab is an open source, portable, and extensible system for the processing and editing of unstructured 3D triangular meshes. The system is aimed to help the processing of the typical not-so-small unstructured models arising in 3D scanning, providing a set of tools for editing, cleaning, healing, inspecting, rendering and converting this kind of meshes.”

I’m mainly interested in using it to reduce the complexity of 3D models.

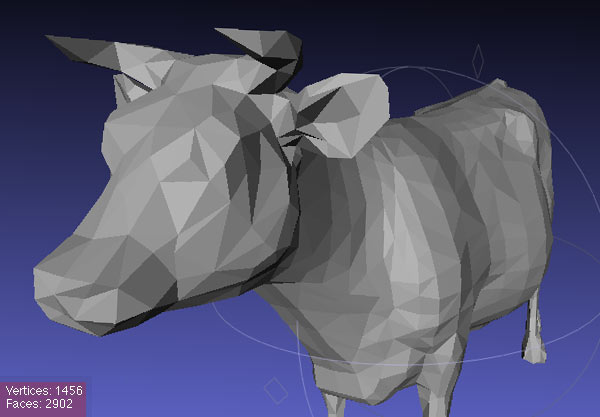

Here is the STL file I created from the original cow in Sketchup, as seen in MeshLab.

Here is the same file after reducing the complexity using the Quadratic Edge Collapse Decimation filter. I still feel like it’s a bit of black magic figuring out exactly what numbers to use, and what checkboxes to check, but this is what I used for this one:

I’m fairly pleased with the results (though I haven’t tried to print it yet) but now that I’ve got a (loose) handle on mesh reduction, I’ll dig into the tutorials on YouTube from MrPMeshLabTutorials, including this one on Decimation.

(Of course I still wish MeshLab had an Undo function.)

Oh, and if you really want to 3D print a cow, this recently added to Thingiverse cow is probably the one you want. :)

Since those guys (and girls!) at the

Since those guys (and girls!) at the