When the Boy Scouts of Troop 501 in Greenfield needed snowshoes for their winter hikes in deep snow, they turned to an American Indian design—and Roman Prodoehl.

Although it was his first venture into snowshoes, Roman Prodoehl of 4429 S. 66th St., Greenfield, has spent the 10 years since his retirement from Falk Corp. concentrating on his woodworking hobby.

One of the boys in Troop 501 knew all about Prodoehl’s work.

Peter Prodoehl grew up knowing how grandpa could turn pieces of wood into something magical.

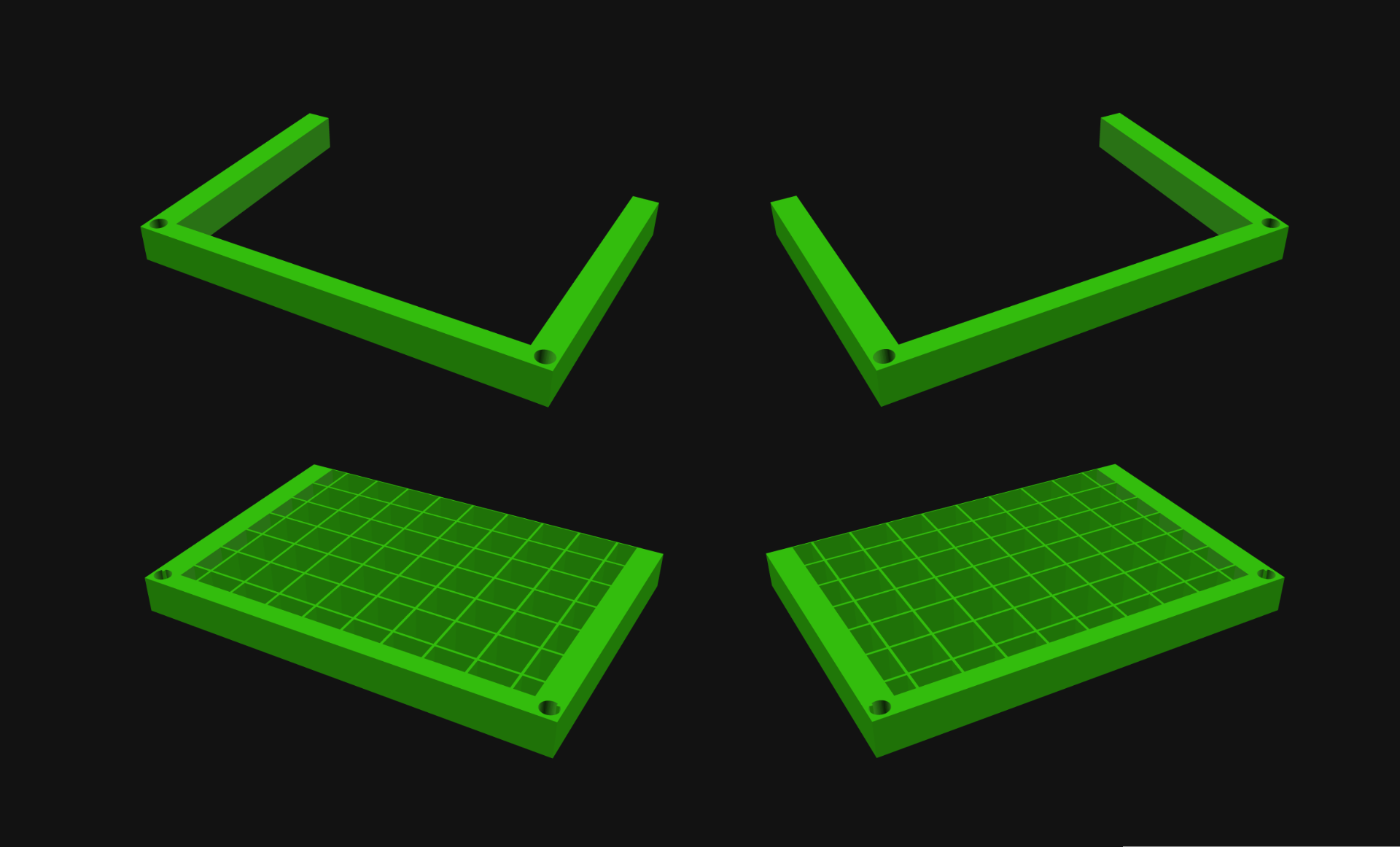

The scoutmaster did the research and found a snowshoe design developed by the American Indians of the northeast-tribes that lived in the area that is now the state of Maine.

Roman Prodoehl took the design and started working on the snowshoes in mid-September.

Now Troop 501 has 11 pairs of snowshoes, and an easier time of it when they hike (with full backpacks) through the deep Wisconsin snow.

“I do it for the love of the work,” says Prodoehl. “My son Ron (Peter’s father) says it keeps me out of mischief!”

Prodoehl didn’t have much time for mischief when he started on the snowshoes.

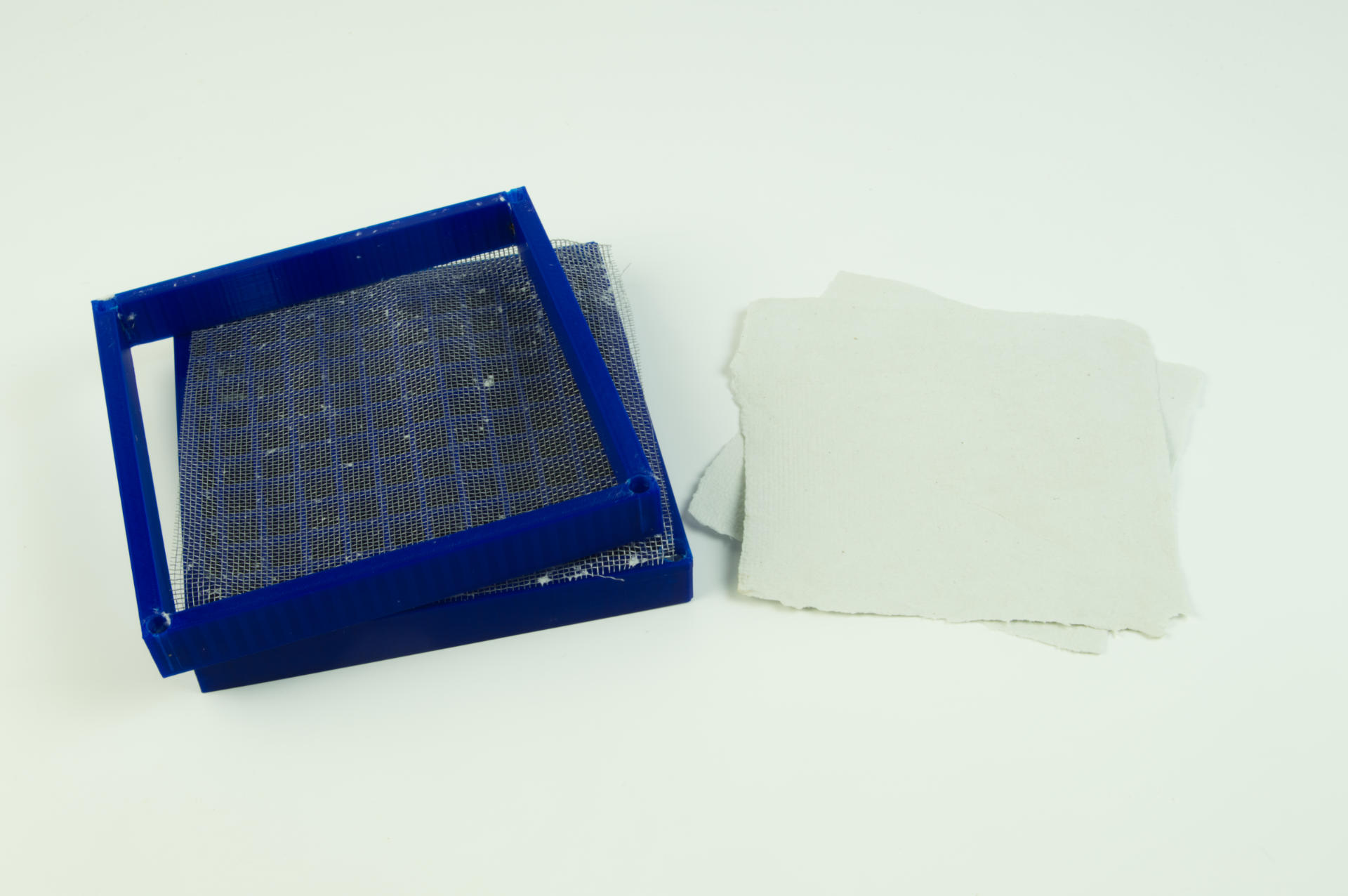

The troop supplied the two 4 by 8 sheets of plywood and Roman supplied the know-how and the help of his wife, Lucille.

Each snowshoe was soaked in hot water for half an hour. Then Prodoehl curved the tips in a woodpress for four hours.

The three-foot long snowshoes, stained brown, are not only authentic but also “custom made”—coming in different sizes depending on the boy.

On a recent hike through Whitnall Park, Troop 501 reported that the snowshoes worked beautifully.

Prodoehl didn’t know it at the time, but 50 years ago, while attending Boys’ Tech woodworking classes, he was learning the techniques needed for the snowshoes. Later he used the same principles in his job in steel fabrication at Falk Corp.

On and off while working at Falk Corp., Prodoehl made use of his woodworking skills—fixing the family wood toboggan after a run-in with a tree, for example—but it is in the last 10 years that he says he begun “to tackle anything.”

That includes a dollhouse for daughter Fleurette and later, over 300 pieces of doll furniture for Fleurette’s children. He patterned all the pieces after furniture in his house.

“I’ve made refrigerators, stoves, davenports, beds, rocking chairs…everything,” he says.

Even a grand piano made out of black walnut.

One Christmas Roman Prodoehl presented family members with handcarved horsedrawn sleighs. Used as centerpieces they are perfect for holding Christmas cards and candy.

Now he is working on a series of shadow boxes for son Ron. One is a miniature old-time saloon.

When summer comes Prodoehl puts away his miniatures and concentrates “on the big stuff”—picnic tables and benches, for example.

“I could be very busy every day of the week,” he says. “People call up and ask if I can make something…”

But although he prefers to take his time “and do what I want to” he can be quickly caught up in a challenge.

That happened recently when Prodoehl was walking through a store and noticed some shoe-boxes-the kind that hold polish and buffing material-selling for $25.

“I looked at them and thought, ‘Oh boy, I can put that together for five bucks,” he says.

So he did. Several of them. And gave them to his grandchildren.

Even after making 22 snowshoes and an entire Boy Scout troop happy, Roman Prodoehl remains stubbornly modest.

“A little whittling. A little carving. It turns out real nice.”

Leave it to grandson Peter to tell the whole story:

“Grandpa can make anything.”