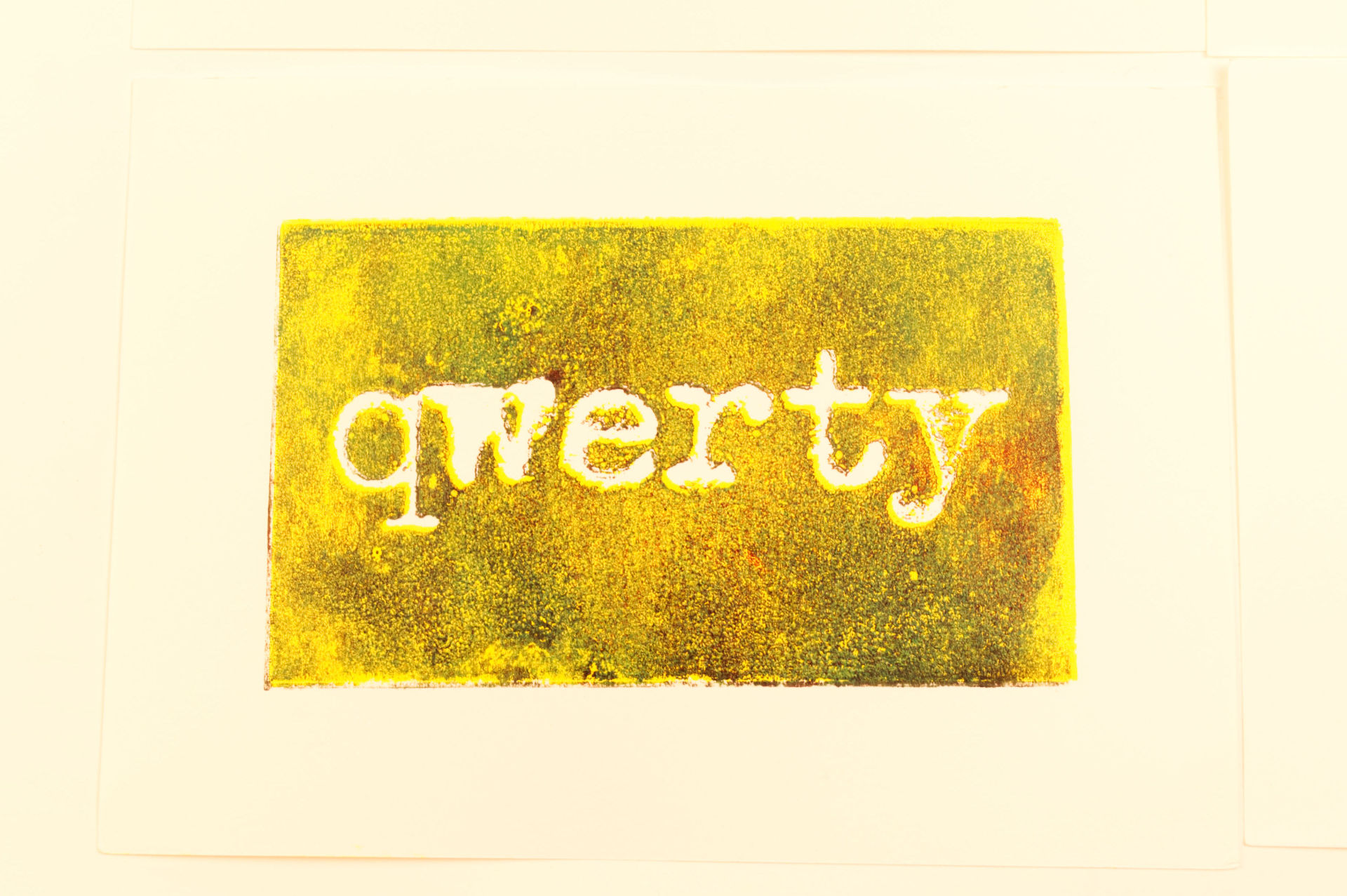

Since I got the press up and running I figured I should put it to good use. I made a plate and made a few prints. One of the things I used to do when I did screenprinting was to do a print, add more ink of a different color, print again, and keep it going. In the end you have (usually) brown ink you can’t really put back into a can since you’ve mixed it all up, so I’d usually have a “brown” can of ink.

Anyway, this is a similar process, where you add more ink with each print. Luckily with this type of printing there seems to be less waste.

Since I recently posted about The Process I’m going to take some time with this post to talk about that…

Of course if you like these prints for their visual qualities, cool. That’s great! You can like them for that, but with everything, there is a story… a narrative… and there’s a process.

Often for me, creation is a exploration. I am extremely lucky that a good amount of the art I make does not need to be commercial art. I don’t have to rely on selling it to survive. I often make things, create things, or attempt to bring something into existence because I am curious. I ask “What if…?” and every now and then I have the means to find out. So let’s go for a journey!

I had attended a meeting for QWERTYFEST MKE, which will be an event focused on typewriters, writing, books, and all that stuff. (If you want a diversion, check out this post about my QWERTY Keyboard.) After the meeting I was thinking about typewriters and how back in the 1990s before we had easy access to computers we would go to Kinko’s and use the IBM Selectric typewriters to create type. This was our primitive method of typesetting: Use a typewriter to type, then blow it up on a copier until you had it large. We used this method to make flyers, and zines, and sticker and t-shirt art, or whatever. It was cheap and easy and fast.

Above is the artwork I used for the printing plate. I got this by starting with the one functional typewriter in my house. An old Royal that sits on our mantle. The ribbon is a bit dried up, but I was able to bang out q w e r t y.

I took the paper I typed on and scanned it into my computer using a Brother MFC-L3770CDW Printer/Copier/Scanner. Sadly it’s a digital thing, and you can see scan lines. I did try to blow it up quite a bit. I may have even printed it and scanned it again. Either way I was not pleased with the outcome, so I did not use it. Maybe I can play with the scanner settings a bit? (Fun Fact: I used to do a ton of scanning at my first internship and then job.)

After the poor performance of the Brother (which is actually a really nice printer and okay scanner) I grabbed the USB Digital Microscope on my desk and actually used that to capture the small type. The microscope can (supposedly) magnify 1000 times. I’m not sure that’s accurate, but that’s what it says on the tin. I did end up using this one. I brought the image into Affinity Photo and messed with the levels and made it monochrome as you can see in the stark black & white image further up the page.

After I made the plates and the prints I remembered I got a nice scanner for Dana’s desk. It’s a Canon CanoScan LiDE400 that can do 4800 dpi resolution. Much higher than the 600 dpi my Brother does. You can even see the grain of the paper!

The other method I probably could have used to magnify the type would be to photograph it with my Nikon DSLR. I didn’t think about that until later.

So as I said, it’s a journey. I now have a number of methods to try next time, and have some idea how they will turn out. I can also do the copy and enlarge thing multiple times. The “copy” feature of the Brother allows for 200% enlargement which is… okay I guess. The idea is that with each copy things degrade a bit, and you get type you cannot get by using a digitally created font. You can see that attempt in the image above. Maybe I should have started with that method… (Note: The Brother can do 400% enlargement. It’s in a submenu.)

Lots more to explore here, and I look forward to it!