It’s been a few years since I’ve posted about laser cut files, and by that I mean, the files I prepare to be used for laser cutting, so I thought I’d do an update.

Right now I typically use a few different laser cutters in the Milwaukee area. At Milwaukee Makerspace there’s a 60 watt ULS and 50 watt ULS, but using a Windows PC with CorelDraw for control, and at Brown Dog Gadgets there’s a 90 watt Chinese laser cutter using CorelDraw (and LaserCut 5.3) though it seems to be a much newer version than used at the Makerspace. I also use a 40 watt Epilog Zing at UWM’s DCRL. The Zing uses Rhino instead of CorelDraw, which may sound weird, but it works.

I’ve got a file workflow that can work with all of these machines… which I’ll explain below.

Here’s what my vector art looks like in Inkscape. You’ll notice that the inside lines are blue, and the outside lines are black. This is so we can set a manual cut order for machines that don’t automatically cut inside lines first. (Some software is smart, and always makes inside cuts first, other software… is not.)

I should note that while doing the design work I may end up with multiple layers. Often I’ll use layers to hold pieces or revisions of a design. For our final file though, we want a single layer.

Let’s pretend my design file is named “Panel Mount.svg”, and it has more than one layer. When I’m happy with my work, and have all the things that will be cut on one layer, I’ll save that file, duplicate it, renaming the dupe to “Panel Mount LC.svg” and then open that file. My original design file (Panel Mount.svg) is now safe and sound, but my new file (Panel Mount LC.svg) is about to get altered.

I usually set all the objects to have no fill. This may not be required for all workflows, but I like to be consistent. (Oh, one more thing… you may need to “convert objects to paths” to get things to work like you expect them to in LaserCut 5.3)

For the stroke I’ll set the outside lines to black… (This may be different depending on your laser cutter software.)

And I’ll set the inside lines to blue. Again, this may depend on the laser cutter software & driver you use. Some allow you to set the order of colors, and some may not. If I need more colors I can use red, green, etc. (Also, if you’re working with a laser cutter operator who is colorblind, ask them what colors they prefer.)

If you want to selectively cut things and only have one color, you can use this trick: Load the file into the laser cutter software (CorelDraw, or whatever) and delete the parts you don’t want to cut, then cut. Then “undo” until all parts are back on the screen, then delete other parts, cut again, and repeat. Not the cleanest method, but it totally works. Don’t move any parts, though you may have to ungroup them, and obviously do not move the thing you are cutting.)

Once I’ve applied all the colors, you can select everything and set the stroke. I set it to 0.03mm. This should set it to “hairline” when you import it into CorelDraw. Rhino also seems to do the right thing. If your stroke is too thick it can cause issues. (Always check for the lines to be set to “hairline” after you import your PDF.)

After you change the stroke the lines may appear very faint. If you can barely see them switch the Display Mode to “outline” which makes every stroke appear a black and sort of beefs up the lines.

At this point I run down the checklist…

- The file has one layer (If it had more, I duped the file and then adjusted the dupe to have just one layer.)

- The file has all objects set to no fill.

- The file has all objects set to 0.03mm stroke.

- The file has different colors for inside and outside cut lines.

Obviously you can do all the file prep stuff (line colors, stroke, etc.) in your master file, and then dupe that one and delete any extra layers. The order isn’t the most important thing here.

Once we’ve made all the changes, we can save our “LC” version of the file. After that, it’s time to use the File menu’s Save a Copy… command to save it as a PDF file. Note that “Convert texts to paths” is selected. This should create a PDF that does not rely on any fonts being installed. If you used text in your file, this is helpful. It does however mean that you cannot edit any text when you import the PDF into other software, as it will have been converted to lines.

Oh, one more thing! Some older versions of CorelDraw seem to have issues importing PDF files created in Inkscape. On Mac OS X, I just open the PDF that Inkscape created, and export it. It somehow fixes the PDF so CorelDraw likes it. Whatever… it works, so I do it!

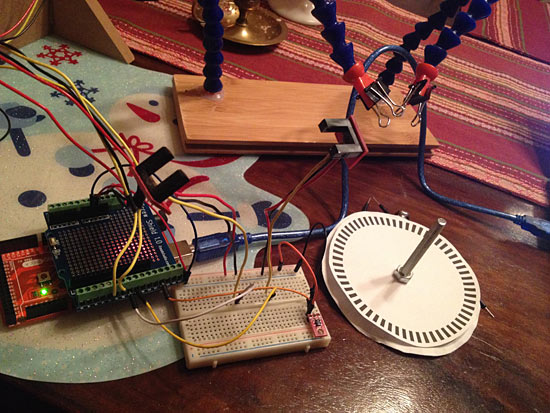

(BTW, the piece I used an as example was for the Simple Dual Axis Solar Tracker from Brown Dog Gadgets.)