Josh Holtz (@joshdholtz@mastodon.social) had posted about his iOS widget called “What’s My Age Again” which does one thing… Tells you your current age! I’m much older than Josh but I guess we both suffer from not knowing our age. I think it’s mainly the issue that my birthday is in middle of the year and I am a different age for the two halves of the year. Anyway… You can read Josh’s post about his widget.

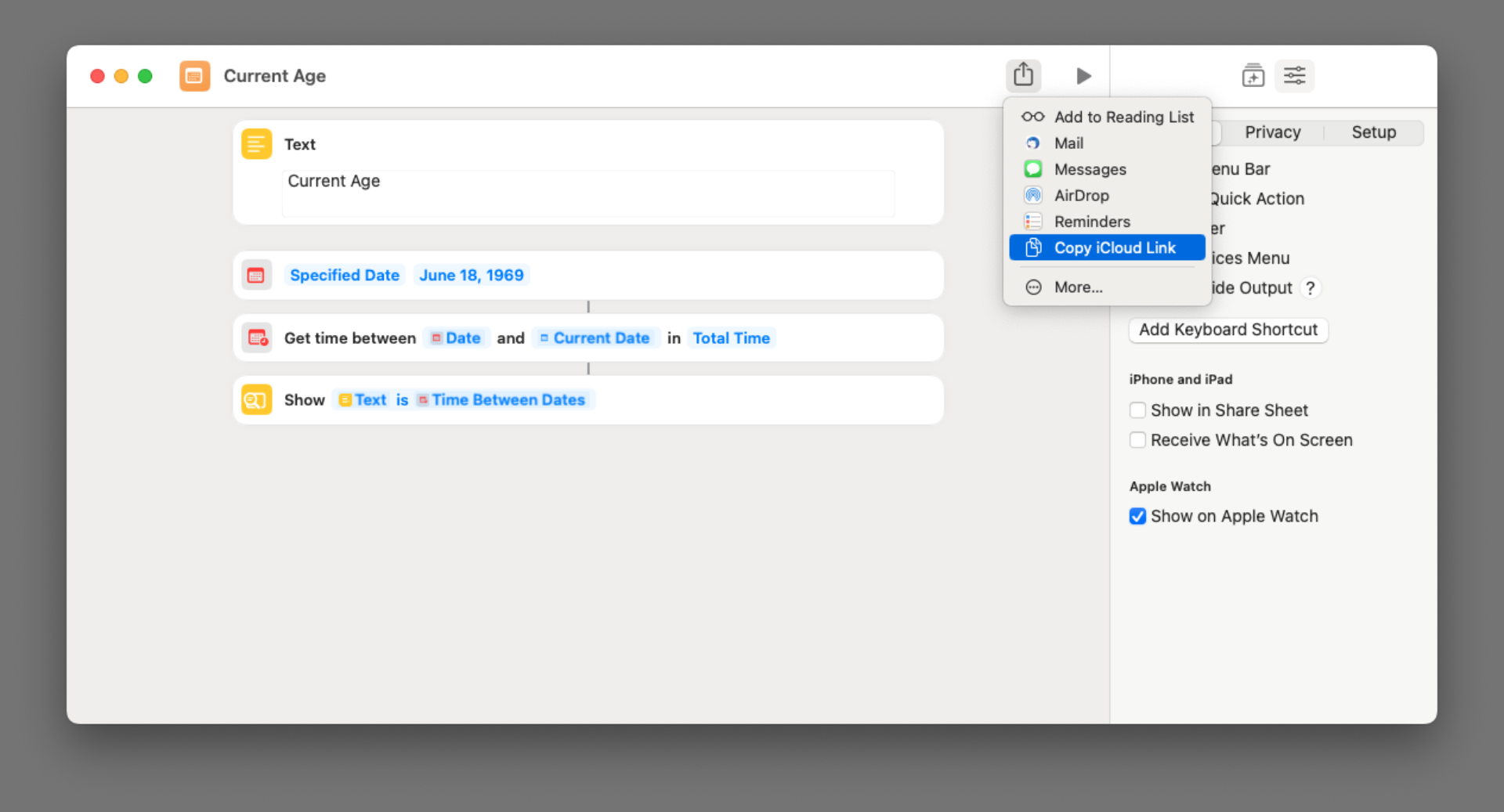

When I started messing around with Shortcuts for iOS and macOS I got inspired by Josh and ended up making my own “Current Age” shortcut which is slightly similar to what Josh created, at least in the output.

My Shortcut doesn’t display my age all the time though, you need to touch the Shortcut to run it, which is fine. I like the fact I was able to easily add this functionality to my phone.

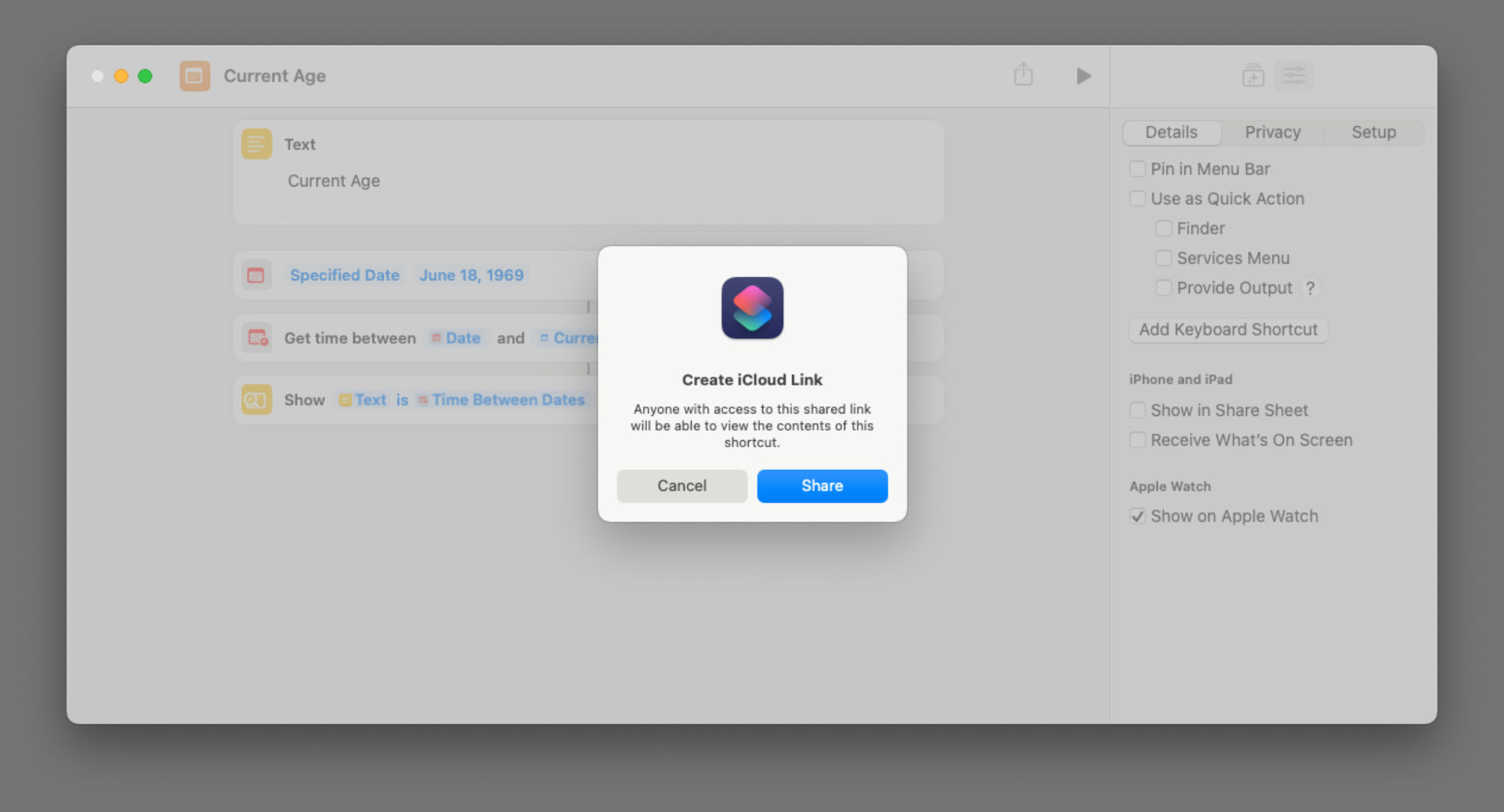

The other neat thing is that you can create Shortcuts on macOS, and some of them will work on the desktop or mobile… and some will work on the Apple Watch I guess. (I don’t have one, and probably will not have one in the future.)

I guess you can also share / publish these Shortcuts so others can use them, you know, so others can know when my birthday is!

I was a user of AppleScript many (many, many) years ago, and while Automator has been around awhile, I never really liked it. And even though it was fun playing with Shortcuts for a bit, on the desktop I was using Quicksilver for a few things, but recently stepped up to Keyboard Maestro, which is simply amazing for automation on macOS, but I should probably save that for another post.