The crew at PCBWay got in touch with me to see if I’d like to try out their service. I’ve used other PCB manufacturers in the past, so I figured I’d give PCBWay a try to see how they worked. The ordering process was not the smoothest, but the boards turned out well, were very affordable, and they got to me pretty quickly.

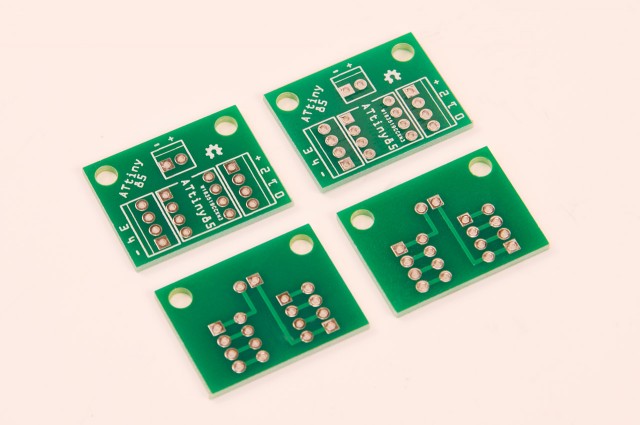

I designed this PCB years ago and I’ve used them a lot in my noisemakers and while I might modify them in the future, they are still pretty useful, so I figured I’d make more.

I had my Gerber files ZIP’d up and ready for upload, so I started the process with PCBWay, which I assumed would be similar to other PCB manufacturers I’ve used. Yup, pretty close. Note that for color you can choose green, red, yellow, blue, white, black, or “none” at the same cost, but choosing purple, matte green or matte black cost bit more. (Not quite double, but more than just a few bucks.) I’m not sure what “none” looks like, but I am curious.

So I added the boards to my cart, and I first noticed that I could not change the quantity. This was a little annoying, as I wanted to try different quantities to see how it affected the price. You can do that, but only at the first step in the process, at the “Online Quote” step, not once it’s in your cart, so make sure you know how many you want before your add them to your cart!

When I went to checkout I then found out I could not check out. Right, seems my boards were “Subject to audit.” Yes, they had to be approved by someone (a human I guess) before I could order them, which seemed weird. (Notice the yellow highlighting I added to the cart image above.)

Now, this is partially my fault, as I didn’t see this the first time I uploaded files. There is a little bit of text on the upload form that shows it could take “10min to 1 hours” for approval. I’m not sure exactly how long it took, as I did this late one night and didn’t get an email about approval until the next day. This was the most annoying part of the ordering process. When I want to order something I don’t want to have to wait hours, or even one hour between putting it in my cart and being able to order it. Perhaps they could make it so that you can place your order, and then if not approved for some reason (?) they could refund the order. Or who knows, maybe this whole “approval” thing is due to some new tariff laws. I have no idea.

Like I said, pricing is good. I got 75 boards for $32. That’s about 43 cents per PCB. These are tiny boards though, so obviously the price per board goes up when you get larger boards. With approval completed (by some human, I guess) I was able to move on to shipping options.

I went with shipping via DHL, which came in at $21, so the order total for 75 boards ended up being $53, making each board cost approximately 71 cents. (Obviously ordering more would probably bring that price down, but I really doubt I need more than 75 of these right now.)

I uploaded the PCB files on July 21st, and they were approved and ordered by July 22nd. Manufacturing was completed by July 25th and they were then shipped via DHL July 27th and I got them by July 30th. That’s about an 8 day turnaround for these printed circuit boards. (With some weekend days in there.) Not bad! For US shipping DHL is probably the best option for getting them fast. There were two cheap shipping options, one being an ePacket (which seems to be how I get most of my eBay electronics delivered) which was $8 but had a 10 to 15 day delivery time frame. There was also “China Post” option which was $7 but showed 25 to 40 days for delivery. Wow. So the ePacket is not too bad if you do not need your boards in a hurry.

The boards from PCBWay look good and got to me fast. They were also very affordable. Overall it was a good experience except for the issue of having to wait until files were approved before ordering and not being able to change quantities once the item is in your cart.