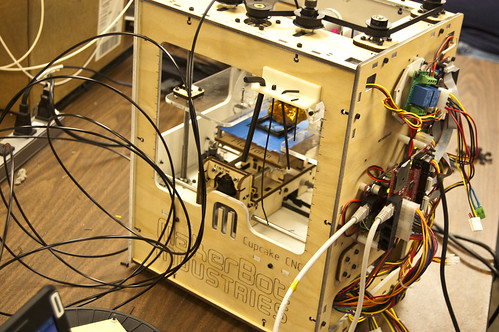

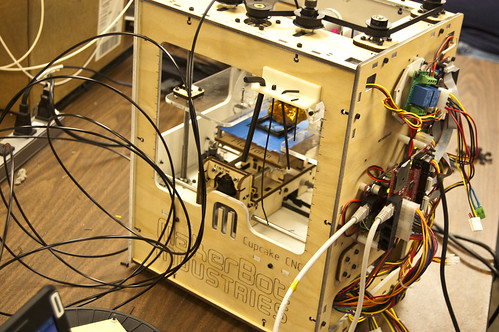

Drew’s MakerBot

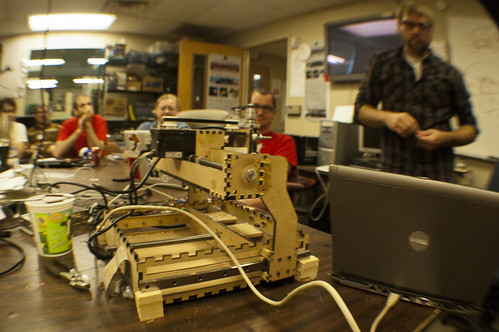

We had a great demo at the Milwaukee Makerspace last week when Drew demoed his MakerBot Cupcake, and if you don’t know by now, the MakerBot is an affordable 3D printer that squirts out hot plastic based on 3D design files you feed it. If you’re not much of a 3D designer, you can browse Thingiverse for some good stuff.

Holder in 3DTin

Our old pal Pehr was also there, and he brought his MakerBot too, and when we were talking about 3D design software he said “Just go to 3DTin.com” and then we did…

The interface was a bit confusing at first, though admittedly I’ve never been able to get very far with 3D software. I did manage to design this thing I’ve called a holder.

Exporting Holder from 3DTin

Once I was done with the design, I was able to export it as an .stl file to my desktop. (There are other export options as well.)

3DTin itself is a simple to use 3D design application that runs completely in a browser. You can use it for free, or for $4.99 you can pay for the “premium” version, which gives you a few more features and hides the ads. I can see playing with this a bit more, or even having the kids give it a try. Meanwhile, I still need to dig into tools like Sketchup, or maybe Blender.

Holder in ReplicatorG

After exporting an .stl file, I loaded it into ReplicatorG to take a look at it. Once in ReplicatorG you can scale, rotate, and move the object as desired. Once I had it centered and scaled properly, I saved the file to an SD card and handed it to Drew to stick into the MakerBot. (As I understand it, you can also just print directly to the MakerBot via USB cable.)

Holder (fresh from the MakerBot)

Once the holder was complete, it looked like this. You can see the strands still in place left from the printing process. These are from the print head moving between the two sides.

Holder (cleaned up)

Here’s what the holder looked like after I trimmed off the strands with an X-ACTO knife. This is obviously a simple object, but so far the process of designing it and printing it was well under an hour.

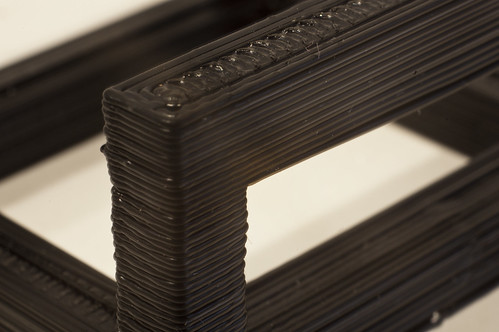

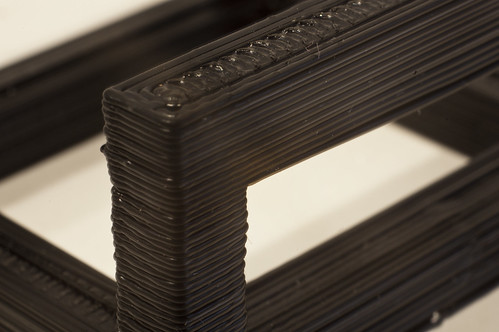

Holder (close-up)

Here’s a close up showing the strands from printing. Commercial 3D printer have much higher resolution, so you don’t really see these lines in the objects they create. Supposedly the MakerBot can be tweaked to run slower for better resolution, but for many purposes, this is still good, and pretty darn impressive.

I’ve got some idea for other things I’d like to design, but for now, you can grab this Holder from 3DTin, and while I had no clue what it would be good for when I designed it, it does seem to work to hold an iPhone in landscape mode, or even as a business card holder.

Big thanks to Drew for the demo and the help in getting started on the MakerBot. I can’t wait to get some serious time with it at the Makerspace.

Oh, it sounds like we’ll also have some good 3D printer action at BarCampMilwaukee6 if you want to come and check it out.

Since those guys (and girls!) at the Milwaukee Makerspace were kind enough to let me join and hang out there, I’ve also started blogging over there. I often post about my own weird projects, but I also try to post about interesting topics, demos we do, or just a typical night of hacking and making.

Since those guys (and girls!) at the Milwaukee Makerspace were kind enough to let me join and hang out there, I’ve also started blogging over there. I often post about my own weird projects, but I also try to post about interesting topics, demos we do, or just a typical night of hacking and making.