This is the method I use for creating 1280×720 (aka, 720p) time lapse video files from a GoPro camera using MPEG Streamclip.

I use the time lapse setting on the GoPro, which creates images that are 2592 pixels wide by 1944 pixels high, though we care less about the pixel width and height, and more about the aspect ratio, which is all wrong for a proper video. (In fact, you can use this method for any still images you wish to finish as a video file.)

I start by compiling all the stills into a video file, and I use QuickTime Player 7 for that. There are other tools, but that’s what I’m currently using, and no the most recent version of QuickTime Player is hobbled crap that won’t work. (Hey Apple, how about fixing that?)

OK, we have our video file, but it’s practically square! Terrible! So let’s fix that…

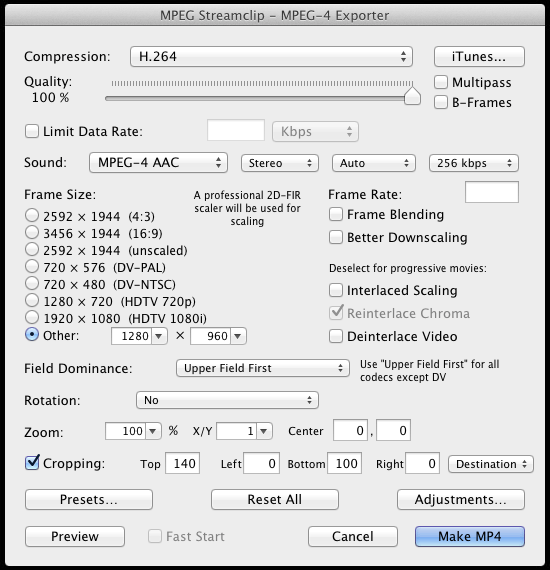

To choose the best crop I usually do a screen grab of the image area, and then open that in Photoshop (or whatever) and size it to 1280 wide. The height should be about 960 (depending on how accurate your screen shot is.) Time for Math! 960 – 720 = 240, so we need to crop 240 pixels from the height. You can easily just skip this step and plug 120 into the top and bottom crop, but this step will let you easily make some other decision, like 140 and 100. As long as your top and bottom crop add up to 240, you’re good.

Sometimes I like to make a marquee that’s 1280 x 720 to get a better idea of the crop… Feel free to skip this step if you don’t need the precision I require in every single thing I do.

OK! Here’s the export window in MPEG Streamclip, where you can see I’ve set the size of the video to “Other” and plugged in the 1280 x 960 values. I then put the 140 and 100 values in the top and bottom crop boxes, respectively. All the other settings are what I typically use for MPEG Streamclip. (The one thing I tend to change which isn’t show here is the ‘Limit Data Rate’ value. But that’s a post for another time. Oh, I didn’t do it here, but you can disable the audio track as well.)

Here’s our final video output at 1280 pixels wide by 720 pixels high. Now, since we started with a video that was 2592 pixels wide by 1944 pixels high, we could actually get all fancy and just select a portion of the video to output at the final resolution. This involved a lot more math, but it’s a possibility, so I’ll leave it up to you to explore.

Now go make some time lapse videos!