I was contacted by someone who really liked the Four Button MIDI Box I had built but was hoping for a less expensive version, so I built one. The Four Button MIDI Box had some specific design requirements regarding size and power, which made it more expensive, but this version (dubbed “LC” for “Low Cost”) does not have such constraints, uses a different source of power, and different components.

This one actually gets power via Micro USB, so any old cheap phone charger should work just fine. Also, while this specific one only does MIDI out via the 5 Pin DIN port, it is capable of doing MIDI out via USB as well. In fact, it can send different data out of the DIN port and the USB port if desired, which is kind of cool.

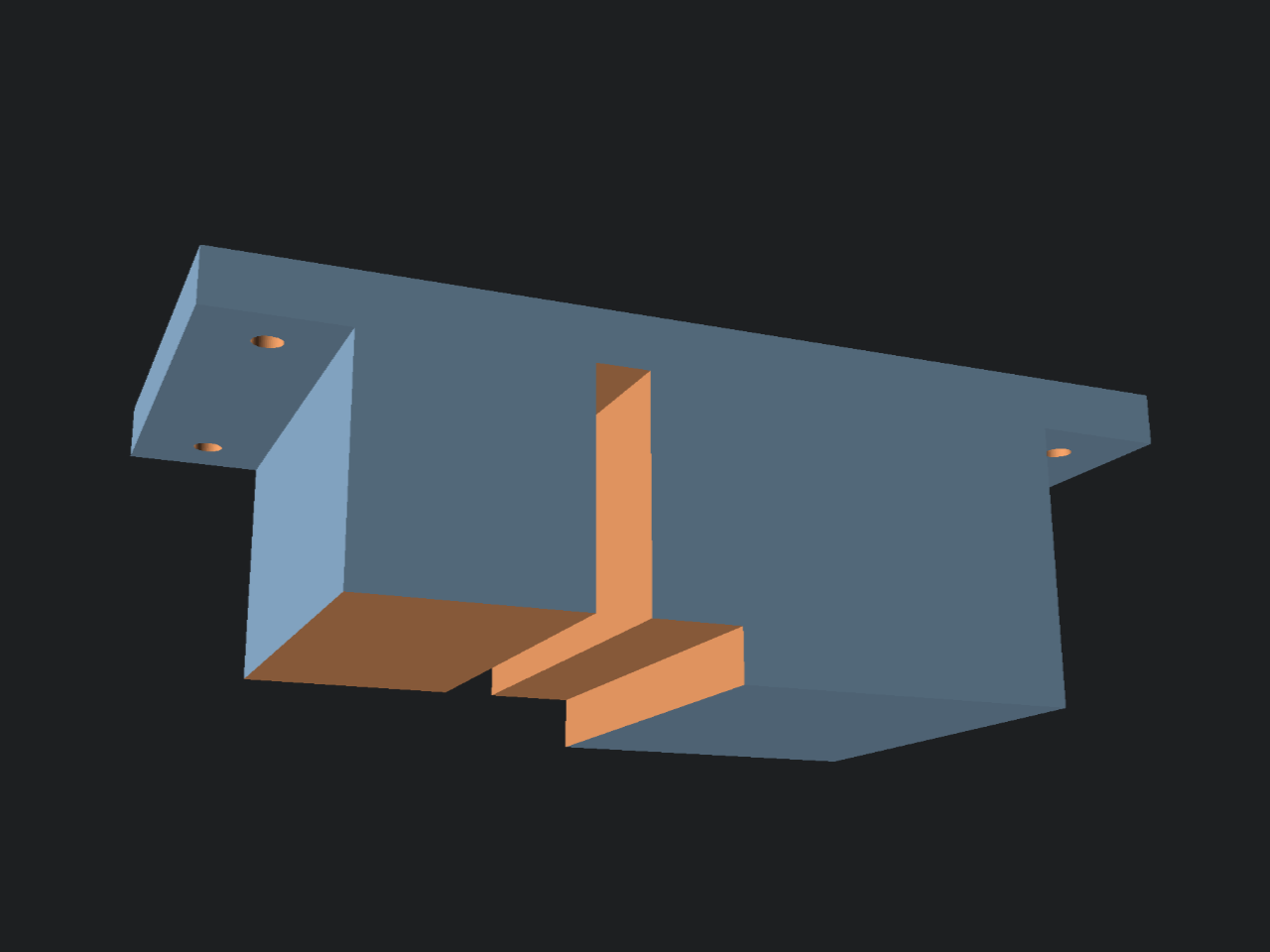

I usually start these kinds of projects doing some simple sketches to get an idea of size & scale of things. Once the customer and I agree on things I do a 3D model of the enclosure so it can be 3D printed.

It usually take between two and three prints to get it perfect. Sometimes I just do partial prints of certain parts (like the holes for the jacks) to make sure it’s all good. This time I did the math wrong so I did three prints to get things perfect. (I also printed a spare right away in case it was needed.)

I’m pretty happy about how this one turned out. Leaving a bit more room for wiring inside the enclosure really helps. I also used silicone wiring which is more flexible and easy to shove into place. In fact, I may build another one right away and add it to the shop in case someone else wants one.