It’s been an interesting six years… Back in 2012 I was just a lowly member of Milwaukee Makerspace who stopped by Kenilworth Open Studios to check out what was happening there, and mainly to meet Frankie Flood.

I remember running into Mike Massie at Kenilworth, and he said he had stopped to talk to Frankie on the third floor, so I went to find him. I’m gonna straight up say I was really excited to meet him, but what threw me off was how excited he was to meet me! It was weird, but totally awesome, and we hit it off right away. It’s safe to say becoming friends with Frankie on that day changed my life. (I’m sure many of his former students would probably say the same.)

A few months later we started the Milwaukee 3D Printing Meetup and later on I somehow got him involved with the e-NABLE project, then I left my job to attend grad school and work with him, then left grad school, then taught at UWM, then Frankie left, and I left, but Kenilworth is still an awesome place to visit each April.

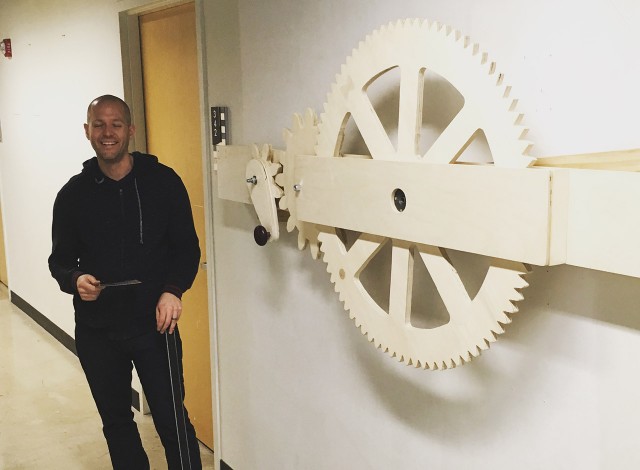

This year I saw co-workers, and former students, and friends, Sometimes people were all three of those. I saw the work of people I really don’t hang out with much, but follow online every day, and much of it was inspiring, and got me excited about art, and design, and making. (More excited than usual!)

Kenilworth (and UWM) will always hold a special place in my heart. I really would not be where I am in my life right now without it, and I’m thankful for that. Also, there’s really nothing that compares to seeing former students doing amazing work and being excited about it. My time teaching at UWM was brief, but I enjoyed every minute of it, and hope I had a positive impact on the students I interacted with.

I look forward to attending Kenilworth Open Studios next year, and for many years to come.